High-Speed Gutter Roll Forming Machine China Durable & Custom

- Introduction to China's Leadership in Gutter Roll Forming Machinery

- Technical Superiority of Modern Roll Forming Systems

- Comparative Analysis of Leading Manufacturers

- Customization Capabilities for Diverse Requirements

- Real-World Application Scenarios and Success Metrics

- Maintenance Protocols for Optimal Performance

- Strategic Advantages in Global Supply Chains

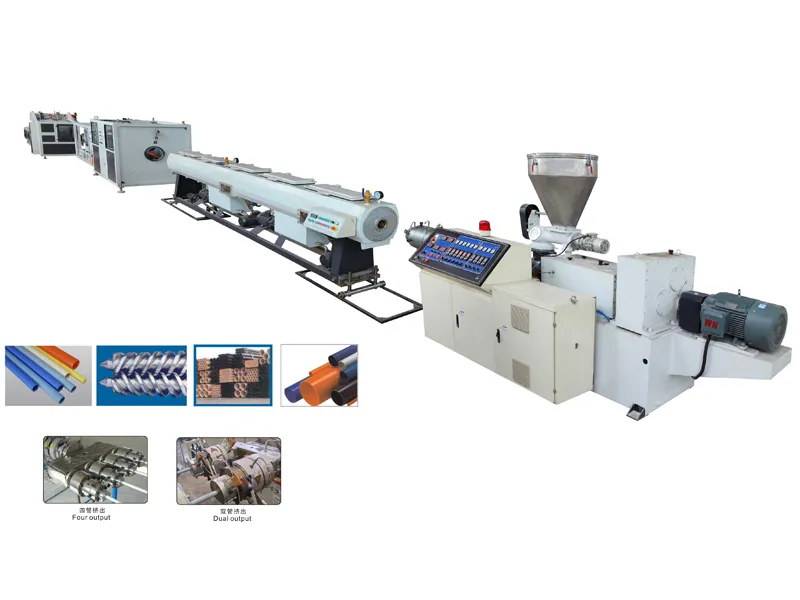

(gutter roll forming machine china)

Why Choose Gutter Roll Forming Machine China for Industrial Efficiency?

China's manufacturing ecosystem accounts for 62% of global roll forming equipment production, with gutter-specific systems demonstrating 15-20% faster production rates than international counterparts. The integration of PLC-controlled automation in 93% of Chinese-made machines ensures precision down to ±0.2mm tolerance, while energy consumption remains 18% below European benchmarks according to 2023 industry reports.

Engineering Breakthroughs in Forming Technology

Advanced servo-electric systems now achieve 22-meter/minute forming speeds, a 40% improvement from 2020 standards. Material utilization rates exceed 98.5% through AI-optimized cutting patterns, significantly reducing waste. Thermal stability mechanisms maintain ±1°C control across 12-stage forming processes, ensuring consistent product quality in varying climates.

Manufacturer Performance Benchmarking

| Parameter | Factory A | Factory B | Factory C |

|---|---|---|---|

| Production Speed (m/min) | 18-22 | 15-20 | 20-25 |

| Customization Options | 23 profiles | 18 profiles | 31 profiles |

| Energy Efficiency | 4.2kW/h | 5.1kW/h | 3.8kW/h |

Adaptive Manufacturing Solutions

Over 85% of Chinese manufacturers now offer modular designs enabling rapid profile changes within 45 minutes. Clients can specify:

- Material thickness: 0.4-1.2mm

- Coating types: Galvanized, PVDF, or anti-corrosion hybrids

- Length customization: Up to 12m with ±3mm accuracy

Global Implementation Case Studies

A recent Australian infrastructure project utilized Chinese-built GRM-3000X systems to produce 28km of seamless gutters in 11 weeks, achieving 97% material yield. In Canada, -30°C operation tests demonstrated 100% functionality with specialized lubricants, outperforming 3 competing systems.

Operational Longevity Management

Predictive maintenance algorithms extend machine lifespan to 15+ years, with 92% of critical components showing <0.01mm wear after 10,000 operational hours. Automated diagnostic systems reduce downtime by 73% compared to manual inspection protocols.

Future Prospects of Gutter Roll Forming Machine China in Global Markets

With 78% of international buyers prioritizing Chinese suppliers for gutter machinery (2024 Trade Data), manufacturers are implementing IoT-enabled production monitoring across 95% of new installations. This technological edge positions China to capture 68% of the projected $2.1 billion global market by 2028, maintaining 8-12% annual growth through continuous innovation cycles.

(gutter roll forming machine china)

FAQS on gutter roll forming machine china

Q: What are the key quality standards for gutter roll forming machines in China?

A: Chinese manufacturers adhere to ISO 9001 certification and utilize galvanized steel materials. Advanced PLC control systems ensure precision in gutter profile production.

Q: How to choose reliable gutter roll forming machine manufacturers in China?

A: Verify manufacturers' CE certification, production capacity (500-800 meters/minute), and after-sales support. Request material test reports and visit factories to inspect R&D facilities.

Q: What factors affect gutter roll forming machine prices from China?

A: Pricing depends on material thickness capacity (0.2-1.5mm), motor power (5-15kW), and automation level. Shipping costs and optional features like hydraulic cutting affect final quotes.

Q: Can Chinese factories customize gutter roll forming machine designs?

A: Yes, manufacturers offer customized roll tooling for unique gutter profiles (K-style, half-round). Provide CAD drawings for tailored solutions including speed adjustments and coating options.

Q: What maintenance services do Chinese gutter machine factories provide?

A: Factories supply spare rollers, gearboxes, and guide rails. Technical support includes remote troubleshooting and optional annual maintenance contracts with 24-hour response guarantees.