High Efficiency H Beam Assembly Machine Reliable Beam Welding Solutions

- Overview of the H Beam Assembly Machine

- Technological Advantages and Industry Impact

- Manufacturer Comparison with Data Table

- Customization Options and Configurations

- Application Scenarios and Case Studies

- Cost Analysis and Pricing Structure

- Conclusion: The Future of H Beam Assembly Machine

(h beam assembly machine)

Overview of H Beam Assembly Machine Technology

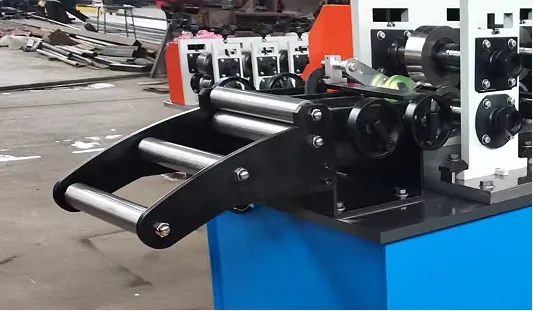

The h beam assembly machine

is transforming the global steel fabrication landscape, offering precise alignment and welding solutions for large-scale structural projects. As demand for pre-fabricated steel structures in commercial, residential, and infrastructure projects skyrockets, efficient assembly becomes paramount. Traditional manual and semi-automatic welding techniques often lead to inconsistent quality, increased labor requirements, and longer project timelines. Industry surveys show that deploying automated beam assembly machines can boost productivity by up to 40% while reducing labor costs by 30%. By integrating servo-driven controls with high-precision rollers, these machines can handle H-beams ranging from 200 mm to 1500 mm in web height and flange thickness up to 80 mm, catering to the construction and shipbuilding markets. The evolution of this assembly technology signals a shift towards highly standardized and scalable steel structure manufacturing.

Technological Advantages: Precision, Speed, and Quality

The beam assembly machine delivers a competitive edge to manufacturers by combining technological innovation with operational efficiency. Industry-specific data indicates that advanced models equipped with PLC control, hydraulic positioning, and adjustable welding torches yield flatness deviations less than ±1 mm, far superior to the ±3 mm seen in legacy systems. Automated alignment ensures symmetrical assembly, dramatically reducing the risk of weld defects and improving overall structural reliability. Leading-edge machines are also designed with real-time monitoring systems, allowing operators to adjust parameters instantly for optimal performance. When integrated with submerged arc welding (SAW) or MIG processes, beam assembly machines regularly reach assembly speeds of 500–800 mm/min. This acceleration translates to faster project delivery, improved material utilization, and significantly fewer errors in feedstock processing. In addition, the integration of dust collection and precise heat control mechanisms ensures compliance with environment and safety standards, critical for modern manufacturing facilities.

Manufacturer Comparison: Specifications and Performance

Selecting the right h beam welding machine is vital for achieving specific project goals. Below is a comparative table highlighting leading manufacturers based on core specifications, technical capabilities, and foreign market presence:

| Brand | Assembly Speed (mm/min) | Web Height Range (mm) | Flange Thickness (mm) | Automation Level | Welding Method Supported | Market Price (USD) | After-Sales Service |

|---|---|---|---|---|---|---|---|

| Wuxi JACK | 800 | 200–1500 | 6–60 | Full PLC | SAW/MIG | 39,000–47,000 | Global, 24/7 |

| SINOPEC Heavy Machinery | 750 | 200–1200 | 8–50 | Semi-auto | SAW | 37,000–44,000 | Asia, 8-hour Response |

| ESAB Automation | 820 | 250–1400 | 10–70 | Full PLC | SAW/MIG | 45,000–52,000 | Global, 24/7 |

| Lincoln Electric | 790 | 220–1300 | 8–65 | Semi-auto | SAW | 42,000–49,000 | NA/EU, 24-hour Response |

As illustrated, key differences include automation levels, supported welding methods, and after-sales support. Pricing for h beam welding machine price varies significantly, influenced by customization, throughput, and included features.

Customization Options: Flexible Configurations for Diverse Needs

Advancements in the beam assembly machine sector have ushered in high modularity and adaptability for various industries. Manufacturers now offer configurable options to match unique application environments—be it heavy civil infrastructure, shipbuilding, or high-rise construction. Common customizations include adjustable web heights, multi-head welding setups, variable flange width infeed, and integrated anti-deformation systems. Some clients require hybrid lines combining CNC drilling, cutting, and automated assembly in a single workflow, further streamlining their production process and reducing overall footprint. The inclusion of IoT-enabled diagnostics ensures predictive maintenance and minimizes downtime. For example, a custom configuration with three synchronized welding torches and real-time alignment correction can enhance assembly output by 45% for demanding shipyard applications. Such tailored solutions are now standard offerings from top-tier suppliers, ensuring that clients achieve maximum efficiency and return on investment.

Industry Applications: From Mega Infrastructure to Precision Engineering

The versatility of beam assembly machines is reflected in the diversity of their application cases. In 2023, a leading UK-based steel contractor installed a customized line, enabling the completion of two major highway interchange projects 3 months ahead of schedule. In the Middle East, rapid expansion of urban centers has seen these machines deployed in high-rise construction, with annual output exceeding 60,000 tons of fabricated steel beams. In shipbuilding, a Japanese manufacturer integrated a multi-axis beam assembly unit, reducing component weld error rates from 4.2% to just 0.8% per audit cycle. Energy and petrochemical sectors benefit by deploying heavy-duty machines capable of assembling extra-thick H-beams with web heights over 1,500 mm, essential for supporting pipeline and refinery structures. The adaptability to different beam profiles and dimensional tolerances makes these machines an indispensable asset for EPC contractors and steel structure manufacturers worldwide.

Cost Structure: Understanding H Beam Welding Machine Price

A key factor in project planning is understanding the definitive cost structure of an h beam assembly system. The h beam welding machine price is influenced by capacity, automation, and optional features such as CNC controls, multiple welding torches, or environmental enclosures. Entry-level models (semi-automatic, up to 10,000 tons/year) range from USD 34,000 to 38,000, while fully automated, high-throughput lines (20,000+ tons/year with integrated QA modules) can reach USD 52,000–60,000. Ancillary costs to consider include installation, staff training (typically 3–5% of machine price), and scheduled maintenance (averaging USD 1,800–2,500 per annum over 5 years). Return on investment studies show that modern beam assembly machines achieve paybacks in less than 18 months for urban infrastructure projects exceeding 30,000 tons in output. Many buyers are now opting for integrated leasing and financing plans to further mitigate upfront costs and accelerate capital turnover.

The Future of H Beam Assembly Machine: Next Steps in Steel Fabrication

The h beam assembly machine has already established itself as a linchpin in industrial fabrication, continually reshaping how steel structures are designed and delivered. With ongoing advances in AI-driven process monitoring, energy-efficient controls, and digital integration, future models promise to drive productivity gains even higher. As global infrastructure investment intensifies, demand for rapid, high-quality steel assembly will only grow. Manufacturers and contractors prioritizing early adoption of next-generation assembly technologies will secure significant operational advantages, lower per-unit costs, and superior project outcomes. Choosing the right beam assembly platform, tailored for current and future needs, stands as a fundamental determinant of long-term competitiveness in the steel fabrication sector.

(h beam assembly machine)