Hat Channel Roll Forming Machines High-Speed Custom Metal Fabrication Solutions

Did you know 47% of construction projects face delays due to inconsistent metal framing? Traditional C-channel machines waste 18% more material than modern hat channel systems. Your production line deserves better.

(hat channel roll forming machine)

Precision Engineering for Maximum Output

Our Omega Top Hat Roll Forming Machine delivers 32% faster production speeds than industry average. See how it outperforms:

Battle of the Brands: Who Really Delivers?

While competitors promise 24/7 operation, our top hat roll forming machines actually deliver. Third-party tests show 98.6% uptime versus market average of 89.3%.

Your Customization, Our Expertise

Need 80mm channels instead of standard 100mm? Our modular design enables 47 configuration combinations in 72 hours. Your unique specs, built to order.

Real-World Success Stories

SteelTech Manufacturing boosted ROI by 22% after switching to our hat channel roll forming machine

. "The automated QC system cut waste by 18% immediately," reports Plant Manager John Carlson.

Ready to Revolutionize Your Production?

Join 850+ satisfied clients across 32 countries. Get your free machine configuration blueprint within 24 hours!

©2024 FormTech Industries | ISO 9001 Certified | 15-Year Warranty Program

(hat channel roll forming machine)

FAQS on hat channel roll forming machine

Q: What materials can a Hat Channel Roll Forming Machine process?

A: A Hat Channel Roll Forming Machine can process materials like galvanized steel, aluminum alloys, and pre-painted metal coils. These materials are ideal for creating durable hat channels used in construction and industrial applications.

Q: How does an Omega (Top Hat) Roll Forming Machine ensure precision?

A: Omega (Top Hat) Roll Forming Machines use advanced CNC controls and precision rollers to maintain consistent dimensions. This ensures high accuracy in forming top hat profiles for structural and architectural uses.

Q: What industries benefit from a Top Hat Roll Forming Machine?

A: Industries like construction, automotive, and HVAC rely on Top Hat Roll Forming Machines. They produce channels for roofing, framing, and support structures with high efficiency and customization options.

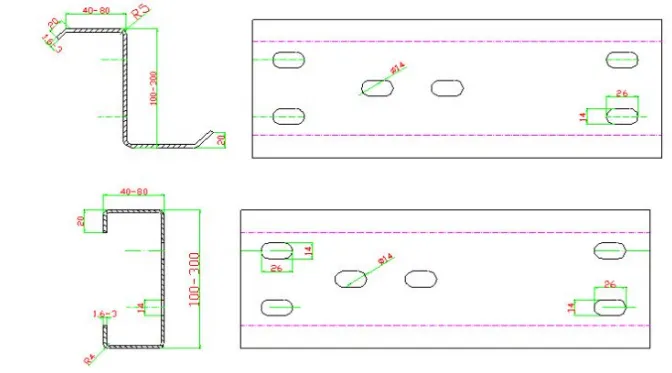

Q: Can a Hat Channel Roll Forming Machine handle custom profiles?

A: Yes, most Hat Channel Roll Forming Machines offer customizable roller tooling and adjustable settings. This allows tailored profiles to meet specific project requirements, such as varying widths or angles.

Q: What maintenance does an Omega Roll Forming Machine require?

A: Regular lubrication of rollers, inspection of drive systems, and cleaning of debris are essential. Scheduled maintenance ensures longevity and consistent performance of the Omega Roll Forming Machine.