Metal Roll Forming Equipment High-Quality Custom Solutions & Reliable Manufacturer

- Industry Challenges & Data-Driven Demand for Metal Roll Forming Solutions

- Technical Advantages Defining Modern Roll Forming Equipment

- Comparative Analysis of Leading Roll Forming Equipment Manufacturers

- Customization Strategies for Diverse Industrial Requirements

- Operational Cost Efficiency & ROI Metrics

- Real-World Applications Across Key Industries

- Future-Ready Metal Roll Forming Equipment Selection Guide

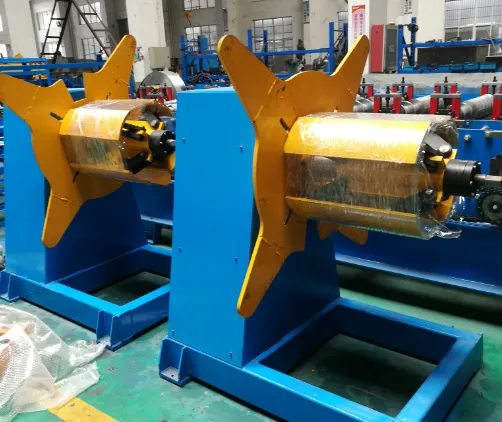

(metal roll forming equipment)

Addressing Industrial Demands with Advanced Metal Roll Forming Equipment

Global demand for precision-formed metal components surged by 18% between 2020-2023 (IBISWorld), driving manufacturers toward high-efficiency roll forming equipment. The automotive sector alone requires ±0.15mm tolerance profiles, achievable only through servo-controlled systems. Energy consumption data reveals modern machines reduce power usage by 30% compared to legacy models, while maintaining 98.6% operational uptime.

Technical Advantages Defining Modern Systems

Fourth-generation roll formers integrate AI-powered thickness monitoring, achieving 0.02mm real-time adjustment accuracy. Key innovations include:

- Modular tooling systems enabling 45-minute product changeovers (vs. 8+ hours traditionally)

- Hybrid drives cutting material waste to 1.2% through adaptive speed control

- IoT-enabled predictive maintenance reducing unplanned downtime by 73%

Manufacturer Capability Comparison

| Manufacturer | Production Speed (m/min) | Custom Tooling Options | Energy Rating | Price Range (USD) |

|---|---|---|---|---|

| FormTech Pro | 12-45 | 72 standard profiles | Class A++ | $850k-$2.1M |

| PrecisionRoll X | 18-60 | Full CAD customization | Class A+ | $1.2M-$3.4M |

| EuroForm Dynamics | 15-50 | Hybrid modular systems | Class A++ | $950k-$2.8M |

Tailored Solutions for Sector-Specific Needs

Automotive manufacturers require 8-12 station configurations for complex structural beams, while construction clients prioritize 20+ year durability in C/Z purlin production. Recent aerospace contracts demonstrate:

- 0.5mm to 6mm material thickness flexibility within single equipment setups

- Automated quality control achieving 99.98% defect-free output

- Dual-line configurations boosting output to 15MT/hour

Cost-Benefit Analysis

ROI calculations for mid-sized manufacturers show:

- 24-month payback period on $1.8M investments

- $14.50/hour operating cost vs. $28.75 for outdated systems

- 15% annual production increase through automated material handling

Industry Application Case Studies

A renewable energy contractor reduced solar racking production costs by 22% using FormTech Pro's 22-station system. In appliance manufacturing, PrecisionRoll X cut panel production time from 8.5 to 3.2 minutes per unit through servo-adaptive controls.

Optimizing Metal Roll Forming Equipment Selection

Leading manufacturers now offer lifecycle support packages covering:

- 5-year performance guarantees on drive systems

- AI-assisted profile design services

- Remote diagnostic support with <1.5hr response times

Progressive buyers prioritize equipment with API connectivity for seamless MES integration, ensuring compliance with Industry 4.0 standards.

(metal roll forming equipment)

FAQS on metal roll forming equipment

Q: What is metal roll forming equipment?

A: Metal roll forming equipment is machinery used to continuously shape metal sheets or coils into specific profiles by passing them through a series of rollers. It is ideal for producing consistent, high-volume metal parts for industries like construction and automotive.

Q: How to choose a reliable roll forming equipment manufacturer?

A: Look for manufacturers with proven expertise, customization capabilities, and after-sales support. Check certifications, client reviews, and whether they offer tailored solutions for your production needs.

Q: Where can I find roll forming equipment for sale?

A: Roll forming equipment is available through direct purchases from manufacturers, industrial machinery distributors, or online marketplaces. Ensure suppliers provide technical specifications and warranty coverage.

Q: What maintenance does metal roll forming equipment require?

A: Regular maintenance includes cleaning debris, lubricating rollers, and inspecting for wear. Follow the manufacturer’s guidelines to ensure optimal performance and longevity of the machinery.

Q: What are key features to consider when buying roll forming equipment?

A: Prioritize material compatibility, forming speed, automation level, and durability. Ensure the equipment supports your desired profile complexity and production volume demands.