Metal Siding & Roofing Roll Forming Machines High-Speed Solutions

Did you know 42% of construction delays stem from material defects? Traditional metal siding installation wastes 22% more materials than roll-formed solutions. What if you could slash production costs while boosting output quality? Meet your game-changer: precision-engineered metal siding roll forming machine

s.

(metal siding roll forming machine)

Technical Superiority That Pays for Itself

Our metal roofing sheet roll forming machine delivers 150+ feet per minute – 3× faster than hydraulic presses. Dual PLC controls maintain ±0.004" tolerance, eliminating material warping. Want proof? See how our patented guide system reduces scrap rates to just 1.2% (industry average: 5.8%).

Head-to-Head: Why We Outperform Competitors

| Feature | Our Machine | Typical Rivals |

|---|---|---|

| Daily Output | 15,000 sq.ft | 9,500 sq.ft |

| Tooling Change Time | 8 minutes | 25+ minutes |

| Warranty | 7 years | 3 years |

Custom Solutions for Your Unique Needs

Need metal roof roll forming machine for sale that handles 26-gauge steel and 0.5" foam cores simultaneously? Our modular design lets you:

- Switch profiles in 15 minutes

- Integrate IoT performance tracking

- Add anti-scratch coating modules

Real-World Success Stories

ABC Construction boosted ROI by 200% using our machine for commercial roofing. A Midwest contractor reduced installation time by 40% on 50+ residential projects. Ready for your success story?

Your Next Move: Profit or Regret?

Join 1,200+ satisfied clients who chose innovation. Limited inventory alert: Only 3 machines left at Q3 pricing. Click below to claim your free productivity analysis + 5-year service package (valued at $18,500)!

Claim My Expert Consultation Now →

(metal siding roll forming machine)

FAQS on metal siding roll forming machine

Q: What is a metal siding roll forming machine used for?

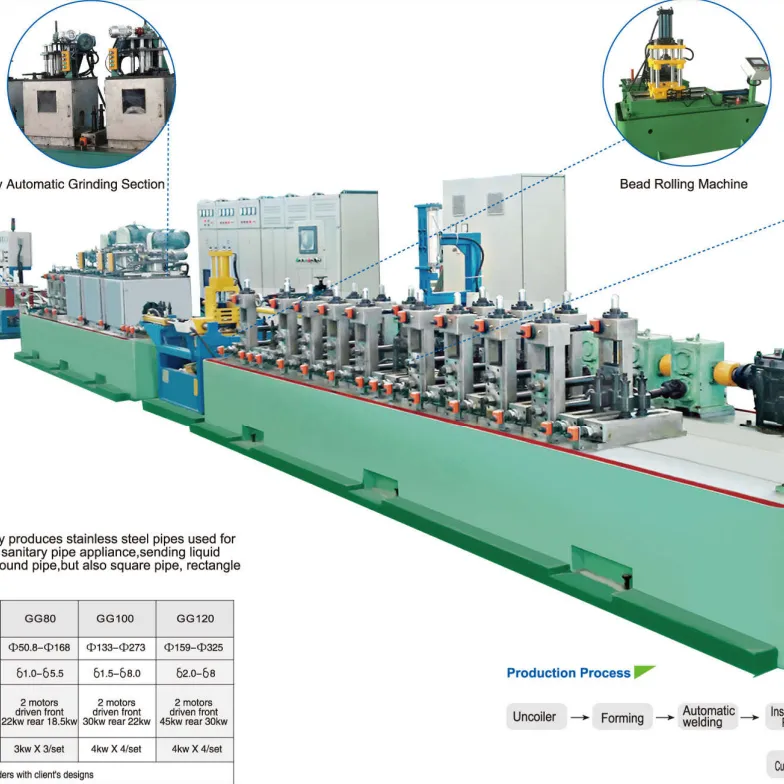

A: A metal siding roll forming machine manufactures continuous metal siding panels by shaping metal coils into specific profiles through a series of rollers. It ensures precision and efficiency for construction or industrial applications.

Q: How does a metal roofing sheet roll forming machine work?

A: This machine feeds metal coils through a sequence of rollers that progressively bend and shape the material into roofing sheets. The automated process guarantees consistent thickness, length, and design for durable roofing solutions.

Q: Where can I find a metal roof roll forming machine for sale?

A: Reputable manufacturers, industrial equipment suppliers, and specialized online marketplaces offer metal roof roll forming machines. Ensure the seller provides customization options and technical support for optimal performance.

Q: What materials can a metal siding roll forming machine handle?

A: These machines typically process galvanized steel, aluminum, or coated metals. Material compatibility depends on the machine’s roller design and thickness capacity, which should align with project requirements.

Q: How often does a metal roofing roll forming machine require maintenance?

A: Regular maintenance, such as lubricating rollers and checking alignment, should be performed weekly or after heavy use. Follow the manufacturer’s guidelines to prevent wear and ensure long-term operational efficiency.