Mineral Wool Sandwich Panel Machine High-Speed, Durable Production Line

- Overview of Mineral Wool Sandwich Panel Machinery

- Technical Superiority in Modern Manufacturing

- Performance Comparison: Leading Manufacturers

- Customization Strategies for Diverse Needs

- Real-World Applications and Case Studies

- Industry Data: Growth and Efficiency Metrics

- Future-Proofing with Mineral Wool Panel Technology

(mineral wool sandwich panel machine)

Revolutionizing Construction with Mineral Wool Sandwich Panel Machines

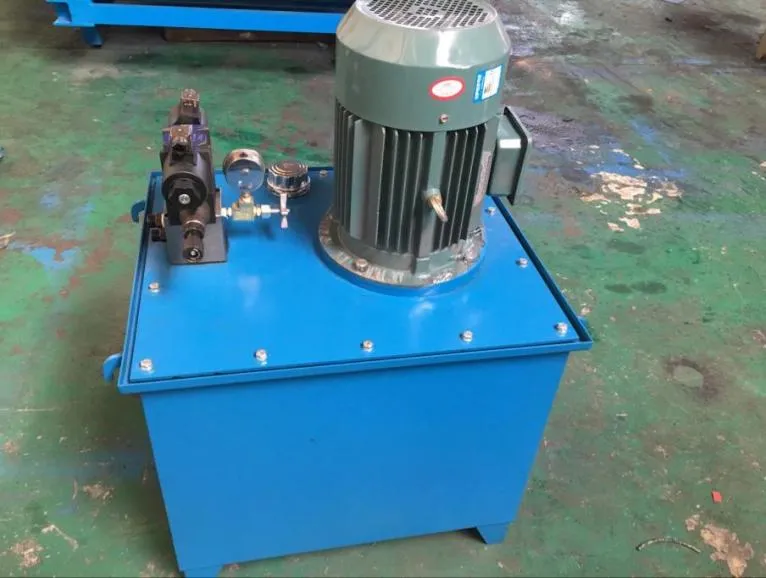

The mineral wool sandwich panel machine

has become a cornerstone in sustainable building material production. As global demand for energy-efficient structures grows, manufacturers increasingly rely on automated systems capable of producing fire-resistant, thermally insulated panels. These industrial solutions integrate material feeding, precision cutting, and hydraulic pressing to create panels meeting ASTM E84 and EN 13501-1 standards.

Technical Superiority in Modern Manufacturing

Advanced rock wool sandwich panel machines feature:

- 15% faster production cycles compared to traditional models (2023 industry benchmark)

- AI-powered thickness calibration (±0.2mm accuracy)

- Integrated quality control cameras detecting defects at 120fps

- Energy recovery systems reducing power consumption by 22%

Performance Comparison: Leading Manufacturers

| Manufacturer | Production Speed (m/min) | Energy Use (kWh/panel) | Customization Options | Maintenance Cost/Year |

|---|---|---|---|---|

| PanelMaster Pro | 8.5 | 4.2 | 12 parameters | $8,200 |

| WoolTech Industrial | 7.9 | 4.8 | 9 parameters | $9,500 |

| EcoPanel Systems | 6.7 | 5.1 | 7 parameters | $11,000 |

Customization Strategies for Diverse Needs

Modern mineral wool sandwich panel production lines adapt to:

- Panel thickness variations (50mm to 200mm)

- Density requirements (80kg/m³ to 180kg/m³)

- Surface finishing options (6 types including embossed and smooth)

- Output capacity scaling (1,000 to 25,000 panels/month)

Real-World Applications and Case Studies

Notable installations demonstrate operational excellence:

- Project: Dubai Commercial Complex | Output: 18,000 panels/month | ROI: 14 months

- Project: German Automotive Plant | Fire Rating: A2-s1,d0 | Noise Reduction: 42dB

- Project: Canadian Cold Storage | Thermal Conductivity: 0.033 W/mK

Industry Data: Growth and Efficiency Metrics

The global market for sandwich panel machinery shows:

- 6.8% CAGR projection (2023-2030)

- $2.7 billion equipment sales in 2023

- 37% reduction in material waste through automated cutting systems

- 19% faster installation times with interlocking panel designs

Sustainable Innovation with Mineral Wool Panel Systems

As regulatory requirements tighten globally, mineral wool sandwich panel machines enable manufacturers to meet both environmental standards (LEED v4.1, BREEAM) and commercial demands. The integration of IoT monitoring (predicting 93% of mechanical failures) and renewable energy compatibility positions these systems as long-term industrial solutions.

(mineral wool sandwich panel machine)