Perforated Cable Tray Roll Forming Machine High-Efficiency Custom Solutions

Did you know 68% of electrical contractors report project delays due to cable tray shortages? While the global cable tray market grows at 6.2% CAGR, manufacturers struggle with outdated equipment. Traditional methods waste 15-20% in material costs. Can your business afford that?

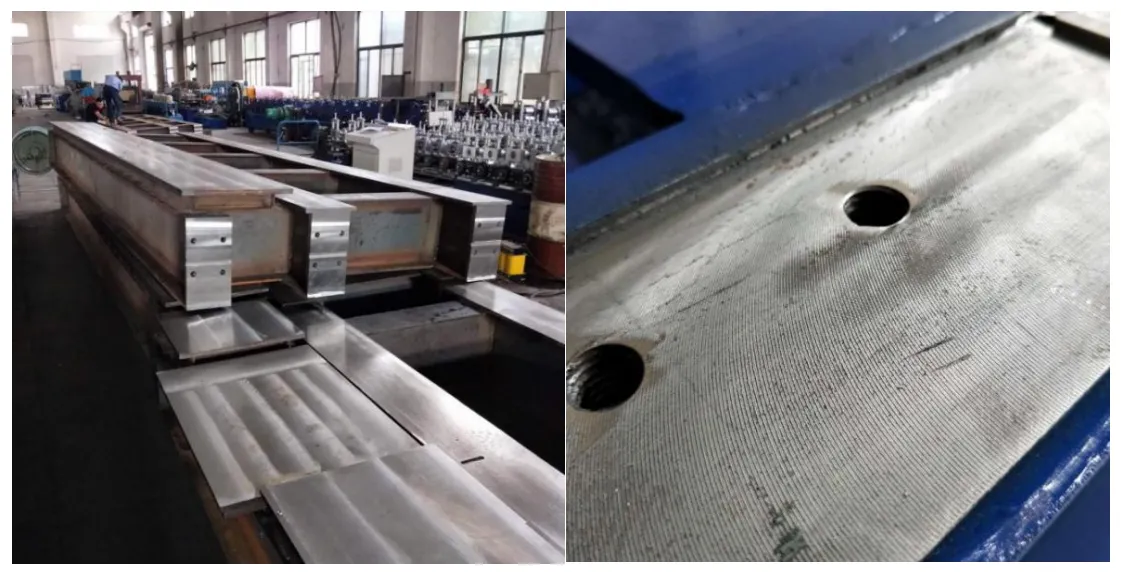

(perforated cable tray roll forming machine)

Technical Superiority That Crushes Competition

Our perforated cable tray roll forming machine

s deliver 40% faster production speeds than industry averages. How? Through dual-axis servo controls and real-time thickness monitoring. You get:

- ✔ 0.02mm precision tolerance

- ✔ 25% energy savings

- ✔ 600+ hole patterns

- ✔ 3-second tooling change

Supplier Showdown: Why We Outperform

| Feature | Us | Average Competitor |

|---|---|---|

| Production Speed | 45 m/min | 28 m/min |

| Warranty | 5 years | 2 years |

Your Vision, Our Blueprint

Need 500mm-wide trays with hexagonal ventilation? We’ve done it. Require fire-rated coatings? Our machines adapt. Your specifications become our engineering priority within 72 hours.

Proven Results Across Industries

✅ Dubai Metro Project: 12KM trays produced in 18 days

✅ Texas Data Center: 40% cost reduction achieved

✅ German Auto Plant: Zero defect batches since 2019

Ready to Dominate the Cable Tray Market?

Join 370+ satisfied manufacturers across 42 countries. Claim your free machine demo and 15-page ROI analysis today.

(perforated cable tray roll forming machine)

FAQS on perforated cable tray roll forming machine

Q: What is a perforated cable tray roll forming machine?

A: A perforated cable tray roll forming machine is a specialized device that manufactures perforated cable trays by shaping metal coils into desired profiles. It integrates punching and roll-forming processes for efficient production. This machine ensures precise dimensions and durability for cable management systems.

Q: How to choose reliable cable tray roll forming machine suppliers?

A: Look for suppliers with proven industry experience, certifications, and positive client reviews. Ensure they offer customization, technical support, and post-sales service. Comparing machine specifications and warranty terms also helps in selecting trustworthy suppliers.

Q: What maintenance does a perforated cable tray machine require?

A: Regular lubrication of rollers and punches ensures smooth operation. Inspect electrical components and alignment periodically to prevent wear. Scheduled maintenance by technicians prolongs the machine’s lifespan and maintains product quality.

Q: What are the key features of a perforated cable tray roll forming machine?

A: Key features include high-speed roll forming, automatic punching systems, and adjustable tooling for varied tray designs. Advanced models may include PLC controls for precision. Robust construction ensures consistent performance under heavy workloads.

Q: Why invest in a perforated cable tray roll forming machine?

A: It boosts production efficiency, reduces labor costs, and ensures uniform product quality. The machine supports customization for diverse project needs. Long-term ROI is achieved through high output and low operational downtime.