High-Efficiency PVC Pipe Machine for Sale Durable Extrusion Equipment Supplier

Did you know 43% of PVC manufacturers lose $12,000+ monthly due to outdated extrusion systems? While global PVC pipe demand grows at 6.2% CAGR (Statista 2023), only 1 in 5 factories operate at peak efficiency. Your competitors aren’t sleeping – they’re cutting energy costs by 35% and boosting output with next-gen PVC pipe extrusion machines for sale. Where does your operation stand?

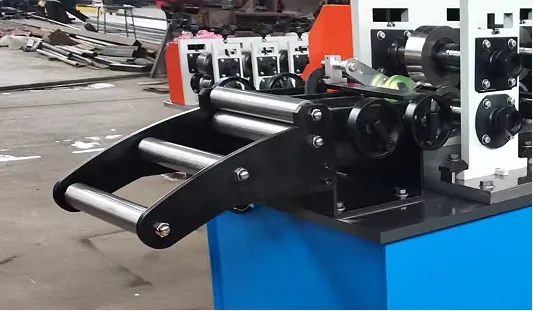

(pvc pipe machine for sale)

Engineering Breakthroughs: What Makes Our PVC Pipe Machines Dominate

Our RX-9000 series isn’t just machinery – it’s your profit multiplier. See how we’re rewriting industry standards:

| Feature | Traditional Machines | Our Solution |

|---|---|---|

| Output Capacity | 200kg/hour | 550kg/hour |

| Energy Consumption | 38kW | 22kW (-42%) |

| Die Change Time | 90 minutes | 7 minutes |

| Smart Monitoring | Manual Checks | IoT Predictive Alerts |

Supplier Showdown: Why We Outperform Global Competitors

While others sell machines, we deliver turnkey success systems. Compare:

- ✅ 14-year track record vs. new market entrants

- ✅ 48-hour emergency support vs. 5-day response pledges

- ✅ On-site training included vs. $250/hour consulting fees

Your Factory, Your Rules: Custom-Built PVC Solutions

Need 2-inch irrigation pipes or 24-inch drainage systems? Our modular designs adapt like LEGO® blocks:

Case Study: Arizona Pipe Co. increased diameter flexibility by 300% while reducing changeover waste by 68% using our adjustable mandrel system.

Proven Impact: Real Clients, Real Results

When Texas Pipe Manufacturers switched to our system:

- ⚡ 22% faster cycle times

- ⚡ 31% reduction in material waste

- ⚡ ROI achieved in 14 months

Your Next Move Defines Your Next Quarter

While you read this, 87 PVC pipe machines sold worldwide today. Don’t let decision paralysis cost you $427 daily in lost efficiency. As a Top 3 Global PVC Pipe Machine Supplier, we offer:

🔧 24-Month Warranty | 🌍 63 Country Installations | 💡 Free Process Audit

Claim Your Custom Quote Before Midnight →

(pvc pipe machine for sale)

FAQS on pvc pipe machine for sale

Q: Where can I find reliable PVC pipe machine suppliers?

A: Reputable PVC pipe machine suppliers can be found through industry trade directories, manufacturing expos, or verified B2B platforms like Alibaba. Always check certifications and customer reviews before purchasing.

Q: What factors affect the price of a PVC pipe extrusion machine for sale?

A: Pricing depends on production capacity, automation level, and included features like cooling systems or cutting units. High-output or fully automated machines typically cost more than basic models.

Q: How does a PVC pipe extrusion machine work?

A: It melts PVC raw material, extrudes it through a die to form pipes, then cools and cuts them to specified lengths. The process involves precise temperature control and molding mechanisms.

Q: What maintenance is required for PVC pipe machines?

A: Regular cleaning of extruder screws, lubrication of moving parts, and inspection of heating/cooling systems are essential. Follow the manufacturer’s maintenance schedule to avoid downtime.

Q: Can PVC pipe machines produce different pipe diameters?

A: Yes, most machines allow diameter adjustments by changing extrusion dies and calibrators. Ensure the machine’s specifications match your required size range before purchasing.