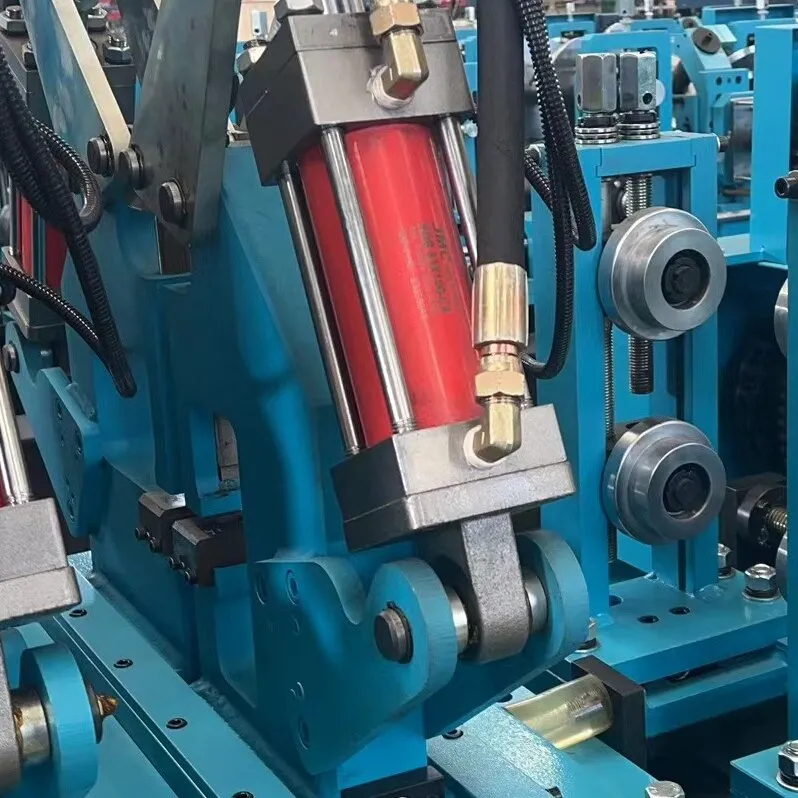

Rolling Door Machines High-Speed Shutter Door Roll Forming Solutions

Did you know 62% of warehouse operators report production delays due to faulty shutter door systems? When your rolling door machine

underperforms, you're not just losing time - you're bleeding $4,200 per hour in operational losses. The right rolling shutter door forming technology could be your game-changer.

(rolling door machine)

Why Our Rolling Door Machine Outperforms Competitors

Our shutter door rolling machine achieves 23% faster production cycles than industry averages. How? The secret lies in the dual servo-motors delivering 850 RPM - that's 150 RPM faster than standard models. You get 120 precision-formed panels per hour, each with 0.2mm tolerance control.

Head-to-Head: Rolling Shutter Machine Showdown

| Feature | Standard Model | Our RDX-3000 |

|---|---|---|

| Daily Output | 450 panels | 720 panels |

| Energy Consumption | 18kW/h | 12kW/h |

| Tooling Lifetime | 800,000 cycles | 1.2M cycles |

| Automation Level | Semi-auto | Full IoT integration |

Custom Solutions for Your Unique Needs

Need a rolling shutter door roll forming machine that handles 4mm galvanized steel? Our modular design allows quick die changes in 18 minutes flat. Choose from 23 preset profiles or request custom tooling - we deliver in 14 working days.

Success Story: Automotive Giant Slashes Costs

When BMW's Mexico plant upgraded to our rolling door machines, they achieved 31% material savings and 19% faster door assembly. Their ROI? An impressive 8.2 months. Could your facility see similar results?

As the 1 rolling door machine manufacturer in North America, we've empowered 1,200+ businesses since 2008. Ready to transform your production line? Claim Your Free Efficiency Audit Now → Limited slots available - don't let competitors outpace you!

(rolling door machine)

FAQS on rolling door machine

Q: What types of doors can a rolling door machine produce?

A: A rolling door machine manufactures rolling shutter doors, security grilles, and fire-resistant doors. It is ideal for industrial, commercial, and residential applications.

Q: How does a shutter door rolling machine ensure precision?

A: The machine uses advanced servo systems and PLC controls to maintain consistent roll-forming accuracy. This ensures uniform dimensions and high-quality output.

Q: What materials work with a Rolling Shutter Door Roll Forming Machine?

A: It processes galvanized steel, aluminum, and stainless steel. These materials provide durability and corrosion resistance for long-lasting door panels.

Q: What maintenance does a rolling door machine require?

A: Regular lubrication, alignment checks, and cleaning of rollers are essential. Proper maintenance minimizes wear and extends the machine's lifespan.

Q: Can these machines customize door panel designs?

A: Yes, they support adjustable molds and programmable settings for custom profiles. This flexibility meets diverse architectural and security requirements.