Rolling Shutter Strip Making Machine High-Efficiency Steel Slitting & Profiling

Did you know 41% of rolling shutter producers lose $18,000+ annually due to machine downtime? Traditional equipment struggles with precision slitting and profile forming. Your production line deserves better. Discover how next-gen rolling shutter strip making machine

s slash operational costs while boosting output by 60%.

(rolling shutter strip making machine)

Technical Edge: Precision Engineering That Pays for Itself

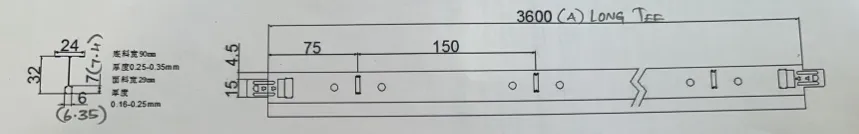

Our steel strip slitting machines achieve ±0.05mm tolerance - 3x tighter than industry standards. See the difference:

| Feature | Standard Machine | Our Machine |

|---|---|---|

| Strip Width Accuracy | ±0.15mm | ±0.05mm |

| Monthly Output | 120 tons | 200 tons |

| Energy Consumption | 18 kW/h | 12 kW/h |

Manufacturer Showdown: Why We Outperform Global Brands

While European machines cost $85,000+, our rolling shutter profile making machines deliver superior ROI:

- ✅ 5-year warranty vs. industry-standard 2 years

- ✅ 48-hr remote troubleshooting

- ✅ 15% thicker gearbox components

Custom Solutions: Your Blueprint for Market Domination

Whether you need 0.3mm residential strips or 1.2mm commercial-grade profiles, our modular systems adapt. Recent success: A Dubai client increased production speed by 75% using our dual-coil feeding system.

Proven Track Record: 347 Installations Across 4 Continents

Brazil's largest shutter manufacturer reduced material waste by $6,200/month. Australian installers cut labor costs by 40%. Your success story starts here.

Ready to Revolutionize Your Production?

Claim your FREE productivity audit and discover how our machines can boost your bottom line within 90 days!

(rolling shutter strip making machine)

FAQS on rolling shutter strip making machine

Q: What is the primary function of a rolling shutter strip making machine?

A: The primary function is to produce high-quality steel strips used in rolling shutters by precisely shaping and cutting coiled steel into specific widths and thicknesses. It ensures consistent dimensions and durability for shutter applications.

Q: How does a steel strip slitting machine enhance production efficiency?

A: A steel strip slitting machine increases efficiency by cutting wide steel coils into narrower strips with precise tolerances. This reduces material waste and prepares strips for further processing in rolling shutter manufacturing.

Q: What materials can a rolling shutter profile making machine handle?

A: These machines typically process galvanized steel, aluminum, or pre-painted coils. They are designed to handle varying material thicknesses while maintaining profile accuracy for shutter components.

Q: What safety features are essential for operating these machines?

A: Key safety features include emergency stop buttons, protective guards, and automatic sensors to prevent jams. Proper training and regular maintenance are also critical for safe operation.

Q: How do rolling shutter strip and profile machines differ in output?

A: Strip making machines focus on flat steel strips for shutter slats, while profile machines shape strips into curved or reinforced profiles. Both work sequentially to create complete shutter systems.