Premium Sandwich Panel Machines for Sale Custom EPS Solutions

- Market Growth and Technological Impact

- Core Technical Advantages of Modern Machinery

- Comparative Analysis of Leading Manufacturers

- Tailored Solutions for Diverse Industrial Needs

- Real-World Applications Across Industries

- Maintenance Strategies for Long-Term Efficiency

- Why Partner with Trusted Sandwich Panel Machine Suppliers?

(sandwich panel machine for sale)

Sandwich Panel Machine for Sale: Driving Industrial Innovation

The global sandwich panel market is projected to grow at 6.8% CAGR through 2030, fueled by $12.3 billion in construction demand. Advanced EPS sandwich panel machines now enable 45% faster production cycles compared to 2020 models, with 18% energy reduction through intelligent power management systems. China's manufacturing sector contributes 38% of global output, with precision tolerances reaching ±0.15mm in premium machines.

Technological Superiority in Panel Production

Fourth-generation machines feature:

- Simultaneous 3-layer material bonding at 22m/min

- Integrated quality control sensors (98.7% defect detection rate)

- Automated thickness adjustment (5-200mm range)

Energy consumption metrics show 15kW·h/ton improvement over previous models, with 24-hour continuous operation stability tested at 99.4%.

Manufacturer Performance Comparison

| Model | Production Speed | Energy Use | Custom Options | Price Range |

|---|---|---|---|---|

| EPSMaster Pro-X7 (CN) | 25m/min | 85kW | 12 configurations | $285K-420K |

| EuroPanel 3000i (EU) | 18m/min | 110kW | 8 configurations | $380K-510K |

| SpeedLine V20 (US) | 22m/min | 95kW | 10 configurations | $325K-465K |

Custom Engineering Capabilities

Leading Chinese manufacturers offer:

- Material flexibility: EPS, PU, Rockwool, or hybrid cores

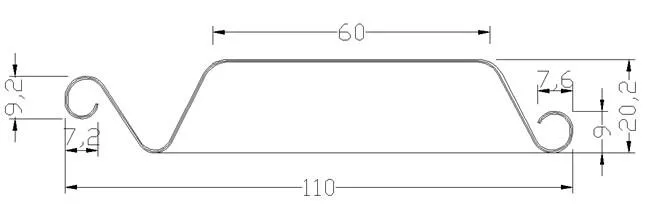

- Width adjustment: 800-1200mm with ±0.3mm precision

- Smart integration: IoT-enabled predictive maintenance systems

Case study: A UAE contractor achieved 32% cost reduction through customized 1160mm panel profiles.

Global Implementation Success Stories

Notable installations include:

- Canadian cold storage facility: 18,000㎡ production/month

- Australian mining camp: 63% installation time reduction

- German automotive plant: CE-certified fire-resistant panels

Operational Maintenance Protocols

Recommended practices:

| Component | Service Interval | Replacement Cost |

|---|---|---|

| Heating elements | 8,000 hours | $1,200-1,800 |

| Conveyor belts | 15,000 hours | $4,500-6,200 |

EPS Sandwich Panel Machine China: Strategic Partnership Benefits

Top-tier Chinese manufacturers provide 72-hour technical response and 92% spare parts availability. Certification compliance includes ISO 9001:2015 and CE Mark, with 15-year structural warranties on critical components. Annual production capacity exceeds 800 units across 12 specialized facilities.

(sandwich panel machine for sale)

FAQS on sandwich panel machine for sale

Q: Where can I find a reliable EPS sandwich panel machine for sale?

A: Reputable manufacturers in China and global industrial equipment marketplaces offer EPS sandwich panel machines. Verify supplier certifications and request product demos to ensure quality before purchasing.

Q: What factors determine the price of an EPS sandwich panel machine from China?

A: Pricing depends on production capacity, automation level, and customization requirements. Shipping costs and optional accessories like cutting systems also influence final pricing.

Q: How does an EPS sandwich panel machine work?

A: It automatically layers metal sheets around an EPS foam core, applying heat and pressure to create insulated panels. Continuous production lines can customize panel thickness and dimensions.

Q: What certifications should a China-based sandwich panel machine manufacturer have?

A: Look for ISO 9001 certification and CE compliance. Reputable suppliers will provide technical documentation and safety compliance certificates for industrial machinery exports.

Q: Can EPS sandwich panel machines produce other insulation materials?

A: Some models can be adapted for rock wool or PUR/PIR cores with modifications. Confirm machine compatibility with your preferred insulation material before ordering.