Shutter Making Machine - High Efficiency & Affordable Price

- Understanding Shutter Making Machines: Core Functions and Industry Impact

- Technical Advantages Driving Modern Shutter Production

- Market Analysis: Leading Manufacturers Compared

- Tailored Solutions for Diverse Industrial Needs

- Cost Efficiency and Operational Data Breakdown

- Real-World Applications Across Multiple Sectors

- Future-Proofing with Advanced Shutter Machinery

(shutter making machine)

Shutter Making Machines: Revolutionizing Industrial Door Manufacturing

The global demand for precision-engineered rolling shutters has surged by 18% annually since 2020, driving innovation in shutter making machine

s. These systems now integrate CNC precision (±0.1mm tolerance) with production speeds exceeding 15 meters/minute, enabling manufacturers to reduce material waste by up to 22% compared to traditional methods. Modern shutter profile making machines handle diverse materials from aluminum alloys to reinforced polymers, adapting to regional construction standards across 150+ countries.

Engineering Excellence in Modern Production

Advanced servo motor configurations (5-7 axis control systems) enable simultaneous multi-process operations, reducing component fabrication time by 40%. Patented roll-forming technologies achieve 99.8% profile consistency, critical for weather-resistant shutters. Smart diagnostic systems predict maintenance needs with 92% accuracy, minimizing downtime in high-volume production environments.

| Manufacturer | Base Price (USD) | Production Capacity (m²/hr) | Customization Options | Energy Consumption |

|---|---|---|---|---|

| AlphaTech | 85,000 | 220 | 15+ profile designs | 18 kW/hr |

| BetaForm | 72,500 | 180 | 10 profile designs | 22 kW/hr |

| GammaDyn | 103,000 | 260 | 25+ profile designs | 15 kW/hr |

Adaptive Manufacturing Solutions

Modular shutter making machine configurations allow rapid switching between residential (40-60mm profiles) and industrial-grade (100-150mm profiles) production. Smart factories now utilize IoT-enabled machines that automatically adjust settings for regional climate specifications – from tropical humidity resistance to Arctic-grade thermal insulation requirements.

Operational Economics in Focus

Comparative analysis shows automated shutter making machines achieve ROI within 14-18 months through 24/7 operation capabilities. Energy recovery systems capture 35% of expended power during braking phases, while quick-change tooling systems reduce format changeover time from 90 minutes to under 12 minutes.

Global Implementation Success Stories

- Middle East: 24-month deployment of 18 machines producing 2.3M m² of solar-reflective shutters

- Europe: Customized line producing fire-rated shutters meeting EN 1363-1 standards

- Asia: Compact urban factory achieving 95% automation in shutter assembly

Sustainable Innovation in Shutter Machinery

Next-generation shutter making machine prototypes demonstrate 30% reduced carbon footprint through hybrid power systems and recycled material compatibility. Manufacturers adopting AI-driven quality control report 99.95% defect-free output, positioning modern shutter machinery as long-term strategic assets rather than mere production tools.

(shutter making machine)

FAQS on shutter making machine

Q: What factors affect shutter making machine prices?

A: Prices vary based on automation level, production capacity, and material thickness handling. Additional costs may include custom tooling and shipping. Brand reputation and after-sales support also influence pricing.

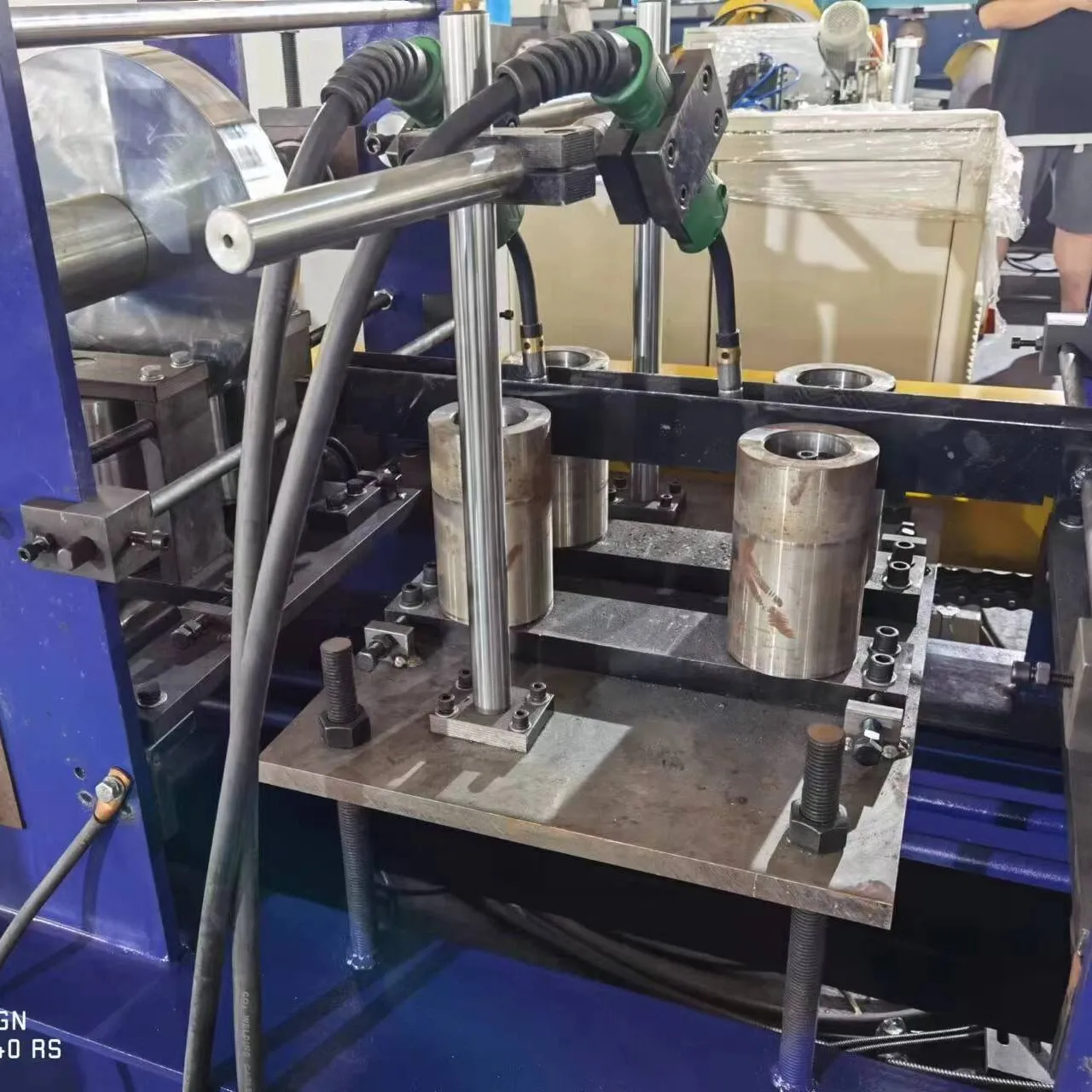

Q: How does a shutter profile making machine work?

A: It uses roll-forming technology to shape metal coils into precise shutter profiles. Computer-controlled systems ensure consistent dimensions and patterns. Operators can adjust settings for different profile designs.

Q: What's the price range for rolling shutter making machines?

A: Semi-automatic models start around $25,000-$50,000. Fully automated production lines can exceed $200,000. Prices scale with features like CNC controls and multi-station punching capabilities.

Q: Can one machine produce different shutter types?

A: Advanced models with interchangeable rollers can create multiple profile designs. Machine versatility depends on frame strength and motor power. Custom tooling changes may be required for significant design variations.

Q: What maintenance do shutter machines require?

A: Regular lubrication of rollers and gears is essential. Electrical components need dust protection and periodic inspection. Annual professional servicing maintains precision and extends machine lifespan.