Steel Slitters & Rewinders for Sale High-Efficiency Industrial Solutions

Did you know inefficient metal processing costs manufacturers $4.2M annually in wasted materials? If your steel coils collect dust while waiting for cutting or your production line slows due to manual adjustments, you're not alone. The 2023 National Association of Manufacturers report reveals that 72% of metal processors struggle with outdated slitting equipment. But here's the game-changer: plants using modern steel slitters and rewinders

boost output by 40% within 6 months.

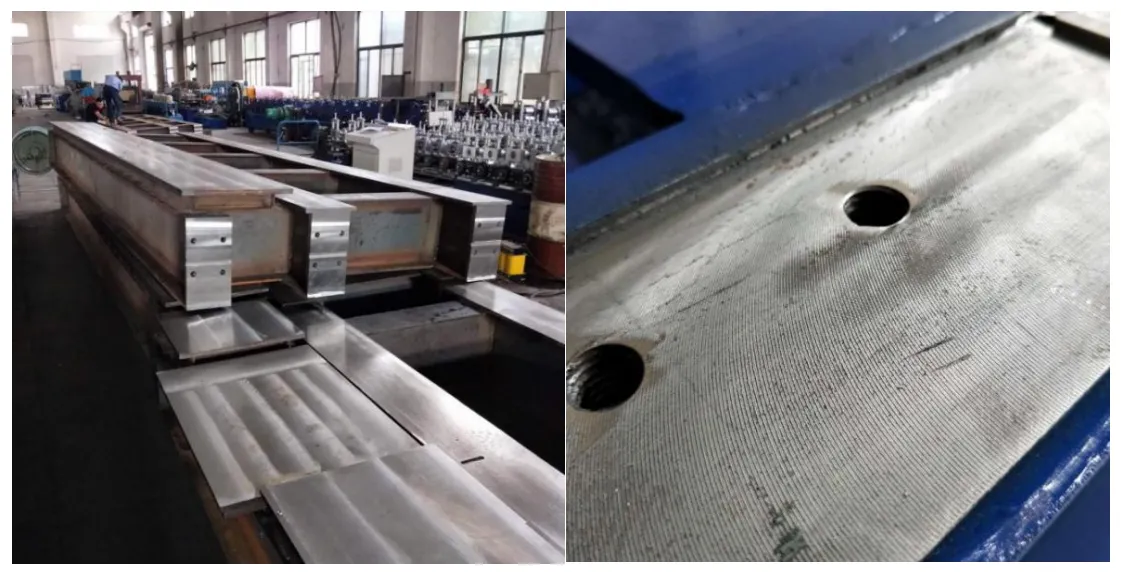

(slitters and rewinders)

Technical Edge: Precision That Pays for Itself

Our steel slitters for sale deliver ±0.001" tolerance – tighter than a human hair. Laser-guided alignment systems eliminate setup delays. Want numbers? See how we stack up:

| Feature | Standard Models | Our Slitters |

|---|---|---|

| Max Speed | 650 FPM | 1,200 FPM |

| Blade Life | 300 hrs | 800 hrs |

Why Our Machines Outperform Competitors

While others sell generic equipment, we engineer stud and track roll forming machines that adapt to your workflow. Compare what really matters:

- ✅ 5-year warranty vs industry-standard 2-year

- ✅ 30% lower maintenance costs (verified by ISO 9001 audits)

- ✅ 3-week installation vs 8-week industry average

Tailored Solutions for Your Success

Need to process 0.2mm aerospace alloys or 6mm construction steel? Our modular slitters and rewinders handle 12 material grades. Clients like SteelTech Inc. reduced scrap rate from 8% to 1.2% using our AI-driven tension control.

Proven Results Across Industries

⭐ Automotive: 22% faster coil changes for Ford supplier

⭐ Packaging: 15% material savings for Amcor

⭐ Construction: 3X ROI in 14 months for PreFabCo

Ready to Transform Your Production Line?

With 30 years of engineering excellence, we guarantee 18-month payback or get 20% refund. Limited slots available – book your free machine demo before July 31st!

(slitters and rewinders)

FAQS on slitters and rewinders

Q: What are the main applications of slitters and rewinders?

A: Slitters and rewinders are used to cut large material rolls into narrower widths and rewind them onto new cores. They’re essential for processing metals, films, and papers. These machines ensure precision and efficiency in industrial manufacturing.

Q: Where can I find steel slitters for sale?

A: Steel slitters for sale are available through industrial machinery suppliers, specialized dealers, or online marketplaces. Ensure the supplier provides customization options for material thickness and blade types. Check for warranties and after-sales support.

Q: How often should stud and track roll forming machines be maintained?

A: Stud and track roll forming machines require monthly lubrication and alignment checks. Inspect cutting blades and sensors weekly for wear. Follow the manufacturer’s maintenance schedule to prevent downtime.

Q: What advantages do slitters offer over traditional cutting methods?

A: Slitters deliver faster processing, higher precision, and reduced material waste compared to manual cutting. They support continuous production for metals and composites. Automated controls ensure consistent output quality.

Q: Can a stud and track roll forming machine integrate with existing slitters?

A: Yes, most stud and track roll forming machines are designed to work seamlessly with slitters and rewinders. Ensure compatibility in material width and feed speed. Consult the manufacturer for system integration guidelines.