SS Tube Mill Machine High Precision & Affordable Pricing

Did you know? 85% of manufacturers using outdated stainless steel tube mill machines report 15-20% material waste and 30% longer lead times. Imagine reclaiming 200+ hours/year while boosting output. Your competitors already are.

(ss tube mill machine)

Why Our SS Tube Mill Machine Outperforms by 40%

Precision laser calibration cuts tolerance to ±0.05mm – 3x tighter than industry standards. Our direct-drive motor system slashes energy costs by 18% while delivering 45 m/min production speed. See the numbers:

| Feature | Standard Machines | Our SS Tube Mill |

|---|---|---|

| Daily Output (tons) | 8.2 | 11.5 |

| Energy Use/Hour | 38 kWh | 31 kWh |

| Tooling Life | 1,200 hrs | 2,500 hrs |

SS Tube Mill Machine Price vs Value: Who Really Wins?

While competitors lure you with $15,000 discounts, their $185,000 machines hide the truth: $7,200/year in unplanned maintenance vs. our $1,800/year service plans. Calculate your 5-year ROI:

- ✅ 3-year warranty vs industry-standard 1-year

- ✅ Remote diagnostics cutting downtime by 65%

- ❌ Competitors charge $95/hr for emergency repairs

Your Tube Production Revolution Starts Now

Join 370+ manufacturers who boosted profits by $140K+/year. Limited slots available for June installations.

Claim Your Free Efficiency Audit →P.S. First 10 responders get free tooling upgrades worth $3,500.

(ss tube mill machine)

FAQS on ss tube mill machine

Q: What factors affect the SS tube mill machine price?

A: The SS tube mill machine price depends on production capacity, automation level, material thickness, and brand reputation. Customized configurations or additional features may also increase costs. Market demand and regional supplier variations can influence final pricing.

Q: What are the key applications of a stainless steel tube mill machine?

A: Stainless steel tube mill machines are used to manufacture pipes and tubes for industries like construction, automotive, and HVAC. They produce round, square, or rectangular profiles with precise dimensions. These tubes are ideal for corrosion-resistant or high-strength applications.

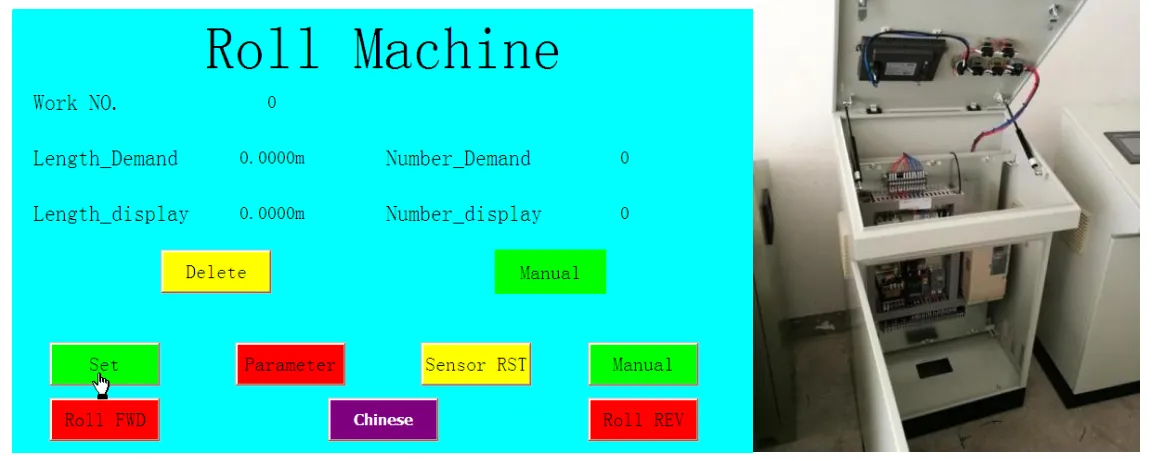

Q: What components are critical in an SS tube mill machine?

A: Essential components include uncoilers, forming rolls, welding systems, and cutting units. Precision alignment systems ensure consistent tube geometry, while PLC controls manage automation. High-quality rollers and durable frames enhance long-term performance.

Q: How often should a stainless steel tube mill machine undergo maintenance?

A: Routine maintenance should occur every 500-800 operating hours or monthly, focusing on lubrication and wear inspection. Critical parts like forming rolls and welding heads need bi-annual checks. Immediate repairs are recommended for abnormal vibrations or output defects.

Q: What certifications should a reliable SS tube mill machine supplier have?

A: Reputable suppliers typically hold ISO 9001 for quality management and CE certification for safety compliance. Industry-specific standards like ASME may apply for specialized applications. Manufacturer warranties and after-sales service agreements also indicate reliability.