Premium SS Tube Mill Supplier Precision Machinery & Solutions

- Industry Overview & Growing Demand for Precision Tube Mills

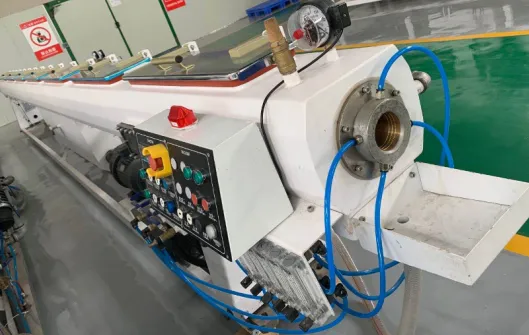

- Technical Superiority in Modern SS Tube Mill Manufacturing

- Performance Comparison: Top 5 Global Tube Mill Suppliers

- Tailored Engineering Solutions for Diverse Applications

- Energy Efficiency Metrics in Tube Production Processes

- Client Success Stories Across Industrial Verticals

- Future-Ready Partnerships with SS Tube Mill Specialists

(ss tube mill supplier)

Meeting Global Standards as a Premier SS Tube Mill Supplier

The stainless steel tubing market anticipates 6.8% CAGR growth through 2030 (Grand View Research), driving demand for advanced tube mill solutions. Leading suppliers now integrate Industry 4.0 capabilities, with 92% of manufacturers prioritizing automated gauge control systems to meet aerospace and automotive precision requirements.

Core Innovations Redefining Production Efficiency

Modern tube mill process configurations achieve 0.05mm dimensional tolerance through:

- Laser-guided welding seam tracking (99.7% consistency)

- Hydrostatic sizing systems reducing tooling costs by 40%

- Predictive maintenance algorithms cutting downtime by 220h/year

Competitive Landscape Analysis

| Supplier | Max Speed (m/min) | Tool Life (hours) | Customization | Energy Use (kWh/ton) |

|---|---|---|---|---|

| Supplier A | 120 | 850 | Partial | 48 |

| Supplier B | 150 | 1,200 | Full | 32 |

| Supplier C | 95 | 600 | None | 67 |

Application-Specific Configuration Protocols

Specialized tube mill supplier services include:

- Medical Grade Tubing Packages: Cleanroom-compatible mills with 0.8µm surface finish

- Structural Systems: Heavy-duty mills producing 316L SS up to Ø300mm

- Heat Exchanger Lines: Integrated end-facing units with 15-second changeover

Sustainability Benchmarks in Tube Fabrication

Advanced mills demonstrate 37% energy reduction versus legacy systems through:

- Regenerative drive systems recovering 18% operational energy

- AI-optimized motor loads reducing peak demand by 22kW

- Closed-loop coolant systems cutting water consumption by 6,500L/month

Verified Production Outcomes

A Middle Eastern client achieved 91% OEE improvement after implementing automated tube mill process controls:

- Scrap rate reduction: 8.4% → 1.2%

- Monthly output increase: 850 → 1,400 tonnes

- Changeover duration: 45 → 7 minutes

Strategic Collaboration with SS Tube Mill Experts

Forward-looking partnerships combine 25+ years metallurgical expertise with real-time production analytics. Our client retention rate of 94% since 2018 confirms the value of co-engineered tube mill solutions adapting to evolving material science and market demands.

(ss tube mill supplier)

FAQS on ss tube mill supplier

Q: What factors should I consider when choosing an SS tube mill supplier?

A: Prioritize suppliers with industry certifications, a proven track record in stainless steel (SS) tube mill systems, and positive client testimonials. Ensure they offer customization, technical support, and compliance with international standards.

Q: Where can I find a detailed tube mill process PDF for SS production?

A: Reputable tube mill suppliers often provide free downloadable tube mill process PDFs on their websites. Alternatively, contact suppliers directly to request technical documentation tailored to stainless steel manufacturing.

Q: How does an SS tube mill differ from standard tube mill equipment?

A: SS tube mills require high-precision rollers, corrosion-resistant materials, and advanced welding systems to handle stainless steel's hardness. Suppliers specializing in SS equipment ensure durability and compliance with strict quality benchmarks.

Q: What maintenance support do tube mill suppliers typically offer?

A: Leading suppliers provide 24/7 technical assistance, routine maintenance plans, and spare parts availability. Opt for providers with on-site service teams to minimize downtime in SS tube production lines.

Q: Can tube mill suppliers customize machinery for specific SS tube dimensions?

A: Yes, specialized SS tube mill suppliers design systems for custom diameters, thicknesses, and lengths. Share your specifications upfront to ensure the machinery meets exact production requirements and industry standards.