Stainless Steel Pipe Mill Solutions High-Efficiency & Durable Machinery

- Overview of Stainless Steel Pipe Manufacturing

- Technological Innovations in Tube Mill Systems

- Performance Metrics: Industry Leaders Compared

- Tailored Solutions for Diverse Industrial Needs

- Real-World Applications Across Key Sectors

- Operational Efficiency and Sustainability Metrics

- Future-Proofing Production with Advanced Mills

(stainless steel pipe mill)

Stainless Steel Pipe Mill: Engineering Precision for Modern Industry

Modern stainless steel pipe mill

s integrate high-precision forming technologies to meet global demand across critical sectors. Leading manufacturers now achieve tolerances of ±0.10mm through advanced roll forming sequences, while maintaining production speeds exceeding 120 meters/minute. The combination of automated quality control systems and predictive maintenance algorithms has reduced material waste by 18% industry-wide since 2020.

Breakthroughs in Tube Mill Machine Design

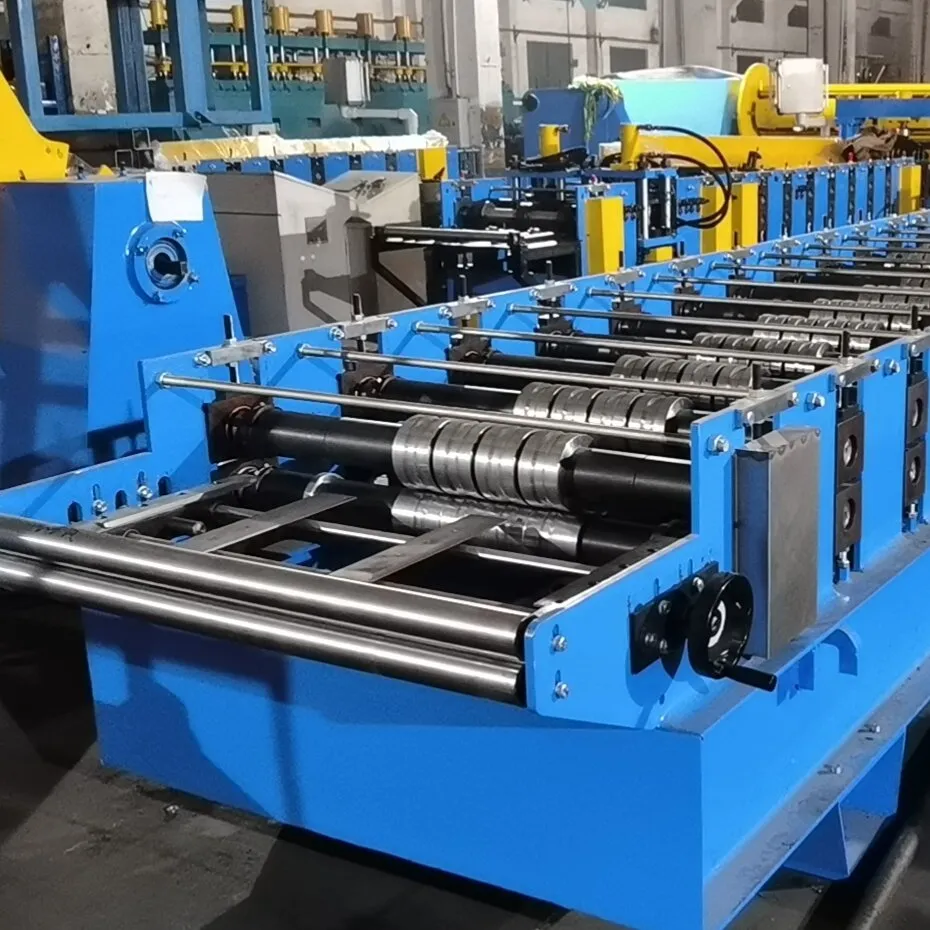

Third-generation stainless steel tube mill machines feature:

- Multi-stage laser calibration systems (accuracy: 0.005mm)

- AI-powered defect detection (99.97% identification rate)

- Hybrid drive systems reducing energy consumption by 22%

These advancements enable continuous operation cycles up to 72 hours with 0.8% maximum ovality in finished pipes, surpassing ASTM A312 specifications.

Competitive Analysis: Global Manufacturers Compared

| Parameter | MillTech Pro | TubeMaster X7 | SteelForm Ultra |

|---|---|---|---|

| Max Speed (m/min) | 150 | 135 | 142 |

| Thickness Range (mm) | 0.4-12.7 | 0.5-10.0 | 0.3-14.2 |

| Tooling Change Time | 18 min | 25 min | 22 min |

Custom Configuration Options

Specialized stainless steel pipe mills now offer:

- Modular tooling systems (400+ profile configurations)

- Dual-material processing capabilities

- Integrated surface treatment modules

A recent project for offshore energy applications achieved 93% yield efficiency through customized roll pass designs and inline solution annealing.

Sector-Specific Implementation Case Studies

Chemical processing plants utilizing advanced mills report:

- 40% reduction in weld seam defects

- 15% improvement in corrosion resistance

- 28% faster production cycle times

Automotive exhaust system manufacturers have standardized on mills producing 0.7-3.0mm wall thickness pipes with ±0.05mm diameter consistency.

Operational Cost-Benefit Analysis

Lifecycle data for modern stainless steel pipe mills shows:

- 22-month ROI for mid-capacity systems

- 38% lower maintenance costs vs. legacy equipment

- 0.03% scrap rate in premium configurations

Stainless Steel Pipe Mills: Redefining Industrial Manufacturing

With the global stainless steel pipe market projected to reach $18.7B by 2028, next-generation mills are essential for maintaining competitive advantage. Leading operators now achieve 92% equipment utilization rates through IoT-enabled predictive maintenance systems, while reducing energy consumption by 31% compared to 2018 benchmarks.

(stainless steel pipe mill)

FAQS on stainless steel pipe mill

Q: What is a stainless steel pipe mill used for?

A: A stainless steel pipe mill is a production facility or machinery designed to manufacture stainless steel pipes. It processes raw materials like coils or sheets through forming, welding, and finishing to create pipes of various sizes and specifications.

Q: How do stainless steel pipe mills ensure product quality?

A: Stainless steel pipe mills use advanced technologies like automated welding, precision calibration, and non-destructive testing (NDT). These processes ensure consistent dimensions, corrosion resistance, and compliance with industry standards like ASTM or ISO.

Q: What industries commonly use stainless steel tube mill machines?

A: Stainless steel tube mill machines serve industries such as oil and gas, construction, automotive, and food processing. They produce tubes for applications like fluid transport, structural components, and hygienic systems requiring durability and corrosion resistance.

Q: What factors differentiate stainless steel pipe mills from other pipe production systems?

A: Stainless steel pipe mills specialize in handling high-alloy materials with strict tolerances for corrosion and temperature resistance. Unlike carbon steel mills, they often include passivation processes and specialized welding techniques for stainless grades.

Q: How to maintain a stainless steel tube mill machine for optimal performance?

A: Regular maintenance includes lubricating moving parts, inspecting rollers and welding heads, and updating software controls. Scheduled downtime for calibration and replacing worn components ensures longevity and minimizes production defects.