High-Speed Steel Slitting Line Machines Precision Coil Cutting Solutions

- Overview of Steel Slitting Line Technology and Market Trends

- Technical Superiority: Precision, Speed, and Material Compatibility

- Comparative Analysis of Leading Steel Slitting Line Manufacturers

- Customized Solutions for Diverse Industrial Requirements

- Real-World Applications: Case Studies Across Industries

- Maintenance and Operational Best Practices

- Future Innovations in Steel Coil Slitting Line Systems

(steel slitting line)

Understanding the Role of Steel Slitting Line Machines

Modern manufacturing relies on advanced machinery like steel slitting line

s to process coiled steel into precise widths. These systems are critical for industries requiring high-volume metal fabrication, such as automotive, construction, and appliance production. According to industry reports, the global demand for steel slitting equipment is projected to grow at a CAGR of 4.2% through 2030, driven by increasing infrastructure investments. A steel coil slitting line typically integrates decoiling, slitting, recoiling, and automation controls, ensuring consistent output with tolerances as tight as ±0.1 mm.

Technical Superiority in Modern Slitting Systems

Leading steel slitting line machines distinguish themselves through:

- Cutting speeds exceeding 600 meters per minute

- Adaptability to material thicknesses from 0.2 mm to 12 mm

- AI-powered defect detection systems reducing waste by 18%

Recent advancements include laser-guided alignment systems that improve edge quality by 32% compared to traditional mechanical methods. Energy-efficient models now reduce power consumption by up to 25% while maintaining throughput.

Manufacturer Performance Comparison

| Manufacturer | Max Speed (m/min) | Thickness Range (mm) | Automation Level | Annual Maintenance Cost ($) |

|---|---|---|---|---|

| Alpha SteelTech | 720 | 0.3-10 | Full | 12,500 |

| Beta Precision | 650 | 0.2-8 | Partial | 9,800 |

| Gamma Industrial | 580 | 0.5-12 | Semi | 14,200 |

Tailored Solutions for Industrial Needs

Customization options address specific operational requirements:

- Dual-motor tension control for specialty alloys

- Modular designs enabling quick width changes (under 15 minutes)

- Integrated IoT monitoring compatible with Industry 4.0 standards

A recent project for an automotive supplier incorporated robotic stacking systems, increasing production efficiency by 22% while reducing manual handling risks.

Application Case Studies

Steel slitting lines demonstrate versatility across sectors:

- Appliance manufacturing: 35% faster material preparation for refrigerator panel production

- Renewable energy: Precision slitting of solar panel mounting components with 99.4% accuracy

- Transportation: Annual processing of 85,000 tons of truck trailer components

Operational Optimization Strategies

Proactive maintenance protocols extend equipment lifespan by 40-60%. Key practices include:

- Bi-weekly blade calibration checks

- Predictive maintenance using vibration analysis sensors

- Operator training programs reducing downtime by 31%

Advancing Steel Coil Slitting Line Technology

The next generation of steel coil slitting lines integrates machine learning algorithms that optimize blade wear patterns, potentially extending tool life by 45%. Hybrid systems combining mechanical and laser slitting are achieving unprecedented precision levels of ±0.05 mm, meeting aerospace-grade specifications. As sustainability pressures increase, manufacturers are developing closed-loop coolant systems that reduce environmental impact by 60% while maintaining cutting performance.

(steel slitting line)

FAQS on steel slitting line

Q: What is a steel slitting line used for?

A: A steel slitting line processes large steel coils into narrower strips. It ensures precise width and edge quality for industries like automotive and construction.

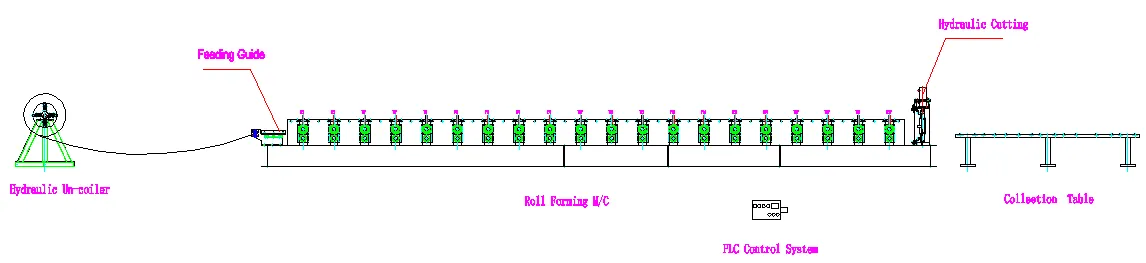

Q: How does a steel slitting line machine work?

A: The machine unwinds a steel coil, feeds it through slitting knives to cut into strips, then recoils the slit material. Automation ensures speed and accuracy.

Q: What industries benefit from a steel coil slitting line?

A: Automotive, appliance manufacturing, and construction industries use slit steel for parts, panels, and structural components due to its customized dimensions.

Q: What are key components of a steel slitting line?

A: Essential parts include decoilers, slitting heads, tension systems, and recoilers. Advanced models feature CNC controls for precision adjustments.

Q: How to maintain a steel slitting line machine?

A: Regular lubrication, blade inspections, and alignment checks are critical. Follow manufacturer guidelines to minimize downtime and ensure consistent performance.