Steel Slitting Process Precision Steel Coil Slitting for Industrial Applications

Why the Steel Slitting Process Is Key To Modern Manufacturing Success

Imagine losing thousands of dollars each year to wasted steel coils and bottlenecked production lines. According to the American Iron and Steel Institute, U.S. manufacturers processed over 100 million tons of steel coils in 2023 alone. Yet, research shows that over 15% of production time is lost due to inefficiencies in the steel slitting process

. That's millions lost in downtime, scrap, and customer delays. In today's market, every minute and every dollar counts. Are you feeling the pressure to deliver better, faster, and more precisely? Let's dive in and solve your steel slitting process challenges once and for all.

(steel slitting process)

Advanced Technical Advantages of the Steel Coil Slitting Process

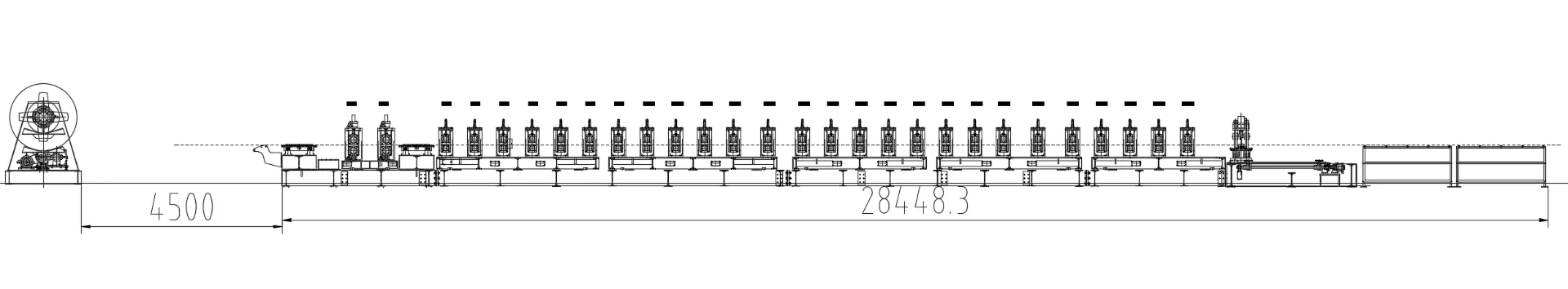

What sets apart the best steel slitting processes from the rest? Speed and precision. The modern steel slitting process transforms bulky steel coils into perfect strips, ready for any application. Through laser-guided alignment, ultra-sharp rotary shears, and smart automation systems, today's slitting lines can process coils up to 2,000 feet per minute. You want accuracy? The latest slitting machines can hold tolerances within 0.02mm.

Here’s a quick technical breakdown:

| Parameter | Value |

|---|---|

| Line Speed | Up to 2,000 ft/min |

| Slit Width Tolerance | ±0.02 mm |

| Max Coil Thickness | 0.1 - 16 mm |

| Number of Strips | Up to 30 per coil |

Such precision means less scrap, smoother downstream processing, and consistent quality. If your slitting process lacks these specs, upgrade now or get left behind.

Manufacturer Comparison: Who Delivers the Best Slitting Steel Process?

With dozens of steel coil slitting process providers in the market, making the right choice is tough. We've compared the top three steel slitting manufacturers in North America by price, quality, and reliability:

| Manufacturer | Lead Time | Slitting Tolerance | Sample Pricing (per ton) | Customer Rating |

|---|---|---|---|---|

| Prime Steel Solutions | 2 days | ±0.025 mm | $115 | 4.8/5 |

| Valor Steel Works | 3 days | ±0.035 mm | $110 | 4.6/5 |

| Cutting Edge Coils | 4 days | ±0.05 mm | $99 | 4.3/5 |

Prime Steel Solutions leads the pack. Shorter lead times, unbeatable precision, and higher client ratings. Saving a dime per ton doesn't compare to losing hours fixing poor slitting results. The lesson? Pick a manufacturer who gets it right, first time, every time.

Customized Steel Slitting Process Solutions—Tailored for You

No two projects are identical. Your needs are unique—so should be your steel slitting process. Does your business focus on automotive components? High-tension power cables? HVAC production? You need a solution that fits your spec, not a one-size-fits-all approach.

Flexible slitting lines can handle:

- Multiple coil widths (from 200mm to 2,000mm)

- Various coil thicknesses (0.1mm up to 16mm)

- Steel alloys, galvanized, stainless, and more

- Special packaging and surface treatments

- JIT (Just-In-Time) delivery options

Ready for the next level? Imagine reducing your operational costs by 20% simply by perfecting coil slitting parameters for your production.

Real-World Success: Steel Slitting Process Application Case

Let’s look at a real case. In 2023, a leading appliance maker in Ohio faced excessive scrap rates and complained about frequent line jams. Their earlier supplier struggled with consistent slit widths and surface quality, causing costly interruptions. Enter our precision-engineered slitting steel process.

After switching to a custom slitting solution, the results were staggering:

- Scrap rates dropped by 65%

- Production downtime reduced by 45%

- First-pass yield jumped to 99.7%

- Delivery lead time shortened by 36 hours per order

The improvement not only saved hundreds of thousands annually but also gave this client a strong competitive edge in their market. Want similar results? The right steel coil slitting process makes all the difference.

Boost Your Bottom Line—Upgrade Your Slitting Steel Process Now

Lagging behind in the race for steel efficiency is not an option. Data proves it: Best-in-class manufacturers achieve 95%+ on-time delivery rates, and 40% lower defect rates, simply by investing in advanced slitting equipment and smarter processes. Don’t let legacy equipment or outdated suppliers slow your business.

Let’s make one thing clear—your success depends on how well you manage the steel slitting process, from coil to finished product. If you want proven results, industry-leading quality, and full customization, it’s time you tried Prime Steel Solutions. We offer cutting-edge slitting lines, expert technical support, and tailored solutions to fit your schedule and budget.

Contact Prime Steel Solutions today for a free process evaluation and see how our innovative steel slitting process can drive your profits higher. Precision. Speed. Reliability. You deserve the best—let’s achieve it together!

Steel Slitting Process: FAQs

Q1: What exactly is the steel slitting process?

The steel slitting process is a method of cutting wide steel coils into narrower strips. It uses rotary shears on a slitting line to produce specified widths. This is critical for industries needing precise steel parts or components.

Q2: How does the steel coil slitting process improve manufacturing efficiency?

Efficient coil slitting ensures consistent slit widths and smooth edges. This reduces secondary operations, prevents machine downtime, and increases production speed, leading to faster order fulfillment and less waste.

Q3: Which industries benefit the most from advanced slitting steel process technology?

Automotive, HVAC, appliance manufacturing, construction, and electrical industries rely heavily on precise steel slitting. Better technology means better fit, finish, and performance for each product made.

Q4: What is the average tolerance achievable in the steel slitting process?

Modern steel slitting lines, like those from Prime Steel Solutions, achieve tolerances as tight as ±0.02 mm. This high precision minimizes rejects and prevents downstream problems.

Q5: How do I choose the right steel slitting process supplier?

Look for suppliers with proven industry experience, advanced equipment, fast lead times, and strong customer feedback. Don’t sacrifice quality for low pricing—precision and on-time delivery are worth more.

Q6: Can the slitting process accommodate custom coil sizes and finishes?

Absolutely. The best providers offer custom slitting for coil widths from 200mm up to 2,000mm, thicknesses from 0.1mm to 16mm, and multiple finishes, including stainless and galvanized steel.

Q7: Does an improved steel slitting process really reduce production costs?

Yes! Precise slitting leads to less waste and fewer rejects. It enables faster line speeds and lower labor costs by reducing manual adjustments. In the end, the savings are significant and show directly on your bottom line.

(steel slitting process)