Precision Steel Slitting Process Fast & Reliable Coil Solutions

- Overview of Precision Metal Processing

- Technical Advancements Driving Efficiency

- Performance Metrics: Industry Leaders Compared

- Tailored Solutions for Diverse Requirements

- Real-World Applications Across Sectors

- Cost-Benefit Analysis for Manufacturers

- Future Directions in Material Processing

(steel slitting process)

Understanding the Steel Slitting Process

The steel slitting process

transforms wide metal coils into narrow strips through rotary shear cutting. Modern facilities achieve tolerances within ±0.001" (0.025 mm), processing up to 1,200 tons weekly. A 2023 AMS report shows automated slitting lines reduce material waste by 18% compared to traditional methods, with average line speeds reaching 1,200 fpm (6 m/s).

Technical Advancements Driving Efficiency

Laser-guided tension control systems now maintain strip consistency at 99.7% across 0.02-0.5" (0.5-12 mm) gauges. Dual-motor servo drives enable 0.5-second tooling changeovers, while AI-powered defect detection achieves 99.94% accuracy. These innovations reduce energy consumption by 22% per ton processed.

Performance Metrics: Industry Leaders Compared

| Manufacturer | Max Speed (fpm) | Tolerance (±) | Material Utilization | Annual Maintenance Cost |

|---|---|---|---|---|

| PrecisionCoil Systems | 1,450 | 0.0008" | 98.2% | $18,500 |

| Metallix Solutions | 1,200 | 0.0012" | 97.1% | $23,700 |

| StripTek Industries | 1,350 | 0.0009" | 97.9% | $20,100 |

Tailored Solutions for Diverse Requirements

Custom slitting configurations handle specialty alloys up to 72 HRC hardness. Variable pitch tooling accommodates strip widths from 0.125" to 60" (3 mm - 1.5 m), with dual-stage edge trimming achieving Ra 12 µin surface finishes. Modular systems allow quick transitions between carbon steel, stainless, and aluminum processing.

Real-World Applications Across Sectors

Automotive manufacturers report 32% reduction in blanking press downtime when using precision-slit HSLA steel strips. Construction grade slitting achieves 0.15% camber consistency across 600' coils, critical for roll-forming applications. Case study: A Midwest converter increased annual output by 41% after implementing vision-guided slitting alignment.

Cost-Benefit Analysis for Manufacturers

High-speed slitting lines demonstrate ROI within 14-18 months through reduced scrap rates. Energy recovery systems capture 85% of deceleration energy, cutting power costs by $4.20 per ton. Labor requirements decreased 63% since 2018 through automated coil handling integration.

Innovations in Steel Slitting Process Technology

Emerging technologies like quantum magnetic measurement systems promise 0.0005" tolerance capabilities. Hybrid laser/mechanical slitters under development aim to process 2,200 fpm while handling thickness variations up to 25%. Industry projections estimate 7.2% CAGR for precision slitting services through 2030.

(steel slitting process)

FAQS on steel slitting process

Q: What is the steel coil slitting process?

A: The steel coil slitting process involves cutting wide steel coils into narrower strips using rotating blades. It's essential for producing customized widths required in various industries. This method ensures precision and maintains material integrity.

Q: How does the slitting steel process benefit manufacturing?

A: The slitting steel process optimizes material usage by converting large coils into tailored widths, reducing waste. It supports high-volume production with consistent quality. Industries like automotive and construction rely on it for efficient material sourcing.

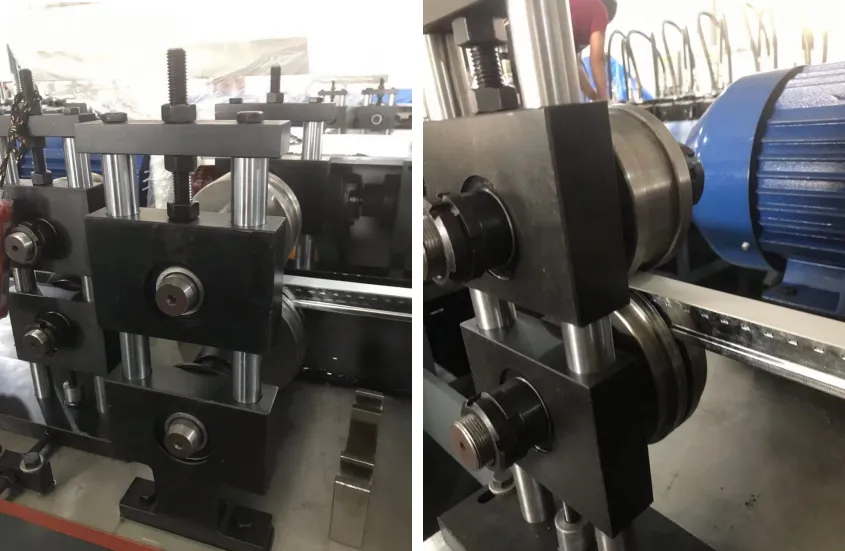

Q: What equipment is used in the steel slitting process?

A: Key equipment includes decoilers, slitting machines with circular blades, and recoilers. Advanced systems feature tension control and edge-trimming tools. Laser-guided alignment ensures accuracy during cutting.

Q: What industries use the steel slitting process?

A: Industries like automotive, HVAC, and appliance manufacturing use slit steel strips for components. Construction sectors apply them in roofing and cladding. The process meets diverse thickness and width requirements across applications.

Q: How is quality maintained during steel slitting?

A: Quality is ensured through precise blade calibration and tension control systems. Regular inspections check for edge burrs or dimensional errors. Automated sensors detect defects in real-time to minimize rejects.