Top Roll Forming Machine Manufacturers | AI Solutions

Top Roll Forming Machine Manufacturers | AI Solutions

Fri . 08, 2025

Roll forming machine manufacturers play a vital role in delivering high-precision solutions for building, automotive, and heavy industry sectors. Whether you are searching for a reliable roll forming machine supplier, optimizing for competitive roll forming machine price, or seeking advanced technology, understanding this sector is pivotal to making informed purchasing decisions.

This comprehensive guide explores current industry trends, core technology parameters, materials and processes, supplier comparisons, bespoke solutions, and real-world case studies—empowering you to partner confidently within the global roll forming market.

This comprehensive guide explores current industry trends, core technology parameters, materials and processes, supplier comparisons, bespoke solutions, and real-world case studies—empowering you to partner confidently within the global roll forming market.

2024 Industry Trends in Roll Forming Machine Manufacturing

According to a MarketsandMarkets report, the global roll forming machine market is projected to reach USD 6.2 Billion by 2026, exhibiting a CAGR of 5.4% from 2021. Key industry drivers:

- Surging demand for lightweight, energy-efficient building components.

- Adoption of IoT-enabled, CNC-controlled roll forming lines for precision and automation.

- Increase in use for solar mounting, automotive crash rails, and high-strength industrial profiles.

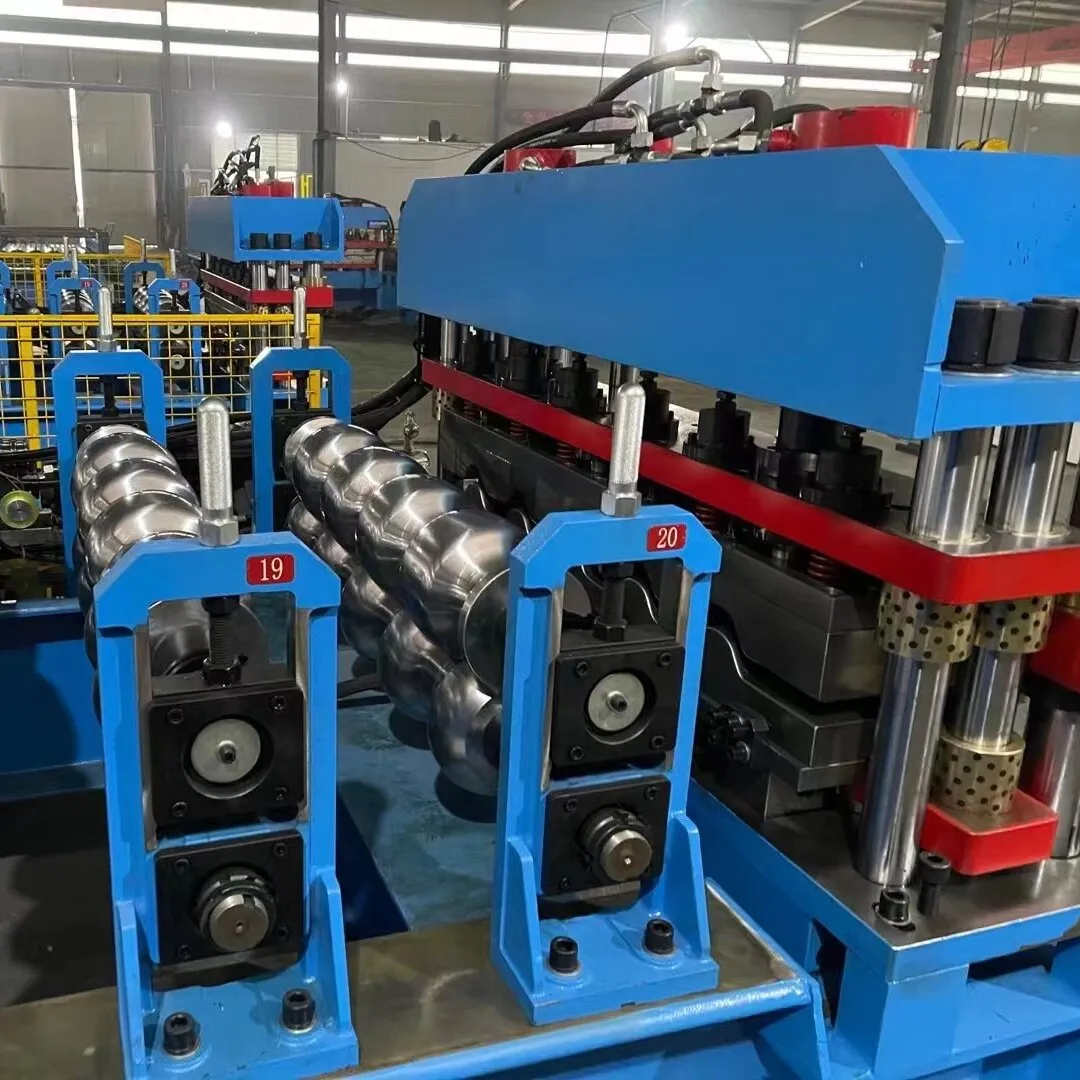

State-of-the-art roll forming line from leading manufacturers

| Manufacturer | Region | Annual Output | Global Clients | Core Certification | Avg. Machine Price (USD) |

|---|---|---|---|---|---|

| Yowin Machinery | China | 380+ Sets | 60+ | ISO9001, CE | 13,000 - 36,000 |

| GASPARINI | Europe | 270+ Sets | 70+ | ISO, UNI EN 10162 | 18,000 - 60,000 |

| Metform | USA | 210+ Sets | 48+ | ANSI, ISO, ASTM | 22,000 - 55,000 |

| Rollforming Solutions | India | 340+ Sets | 55+ | ISO9001, CE | 8,800 - 29,500 |

| Hangzhou Roll Forming Tech | China | 390+ Sets | 80+ | CE, ISO | 11,000 - 38,000 |

Manufacturing Process of Roll Forming Machines

Top roll forming machine manufacturers follow a sophisticated and standardized manufacturing workflow to guarantee product consistency and high performance.

1. Material Selection

High-grade steel/iron alloys screened for core components.

2. Forging/Casting

CNC-controlled forging & casting of stands, rollers.

3. Machining

Precision CNC, turning & grinding for ±0.02mm tolerance.

4. Assembly

All units assembled under ISO & CE protocols.

5. Electrical Integration

Install motors, PLC panels, safety systems (ANSI); wiring & testing.

6. Calibration & QC Testing

Run-in phase using load profiles, COF testing; inspection to ISO 9001.

- Materials: Forged alloy steels (42CrMo, 45#), hardened for longevity.

- Standards: Full compliance with ISO9001, ANSI, DIN.

- Inspection: Coordinate Measuring Machine (CMM), ultrasonic crack testing, & hardness evaluation ensure reliability.

- Longevity: Typical service span > 15 years in heavy cycles (validated by client records).

CNC-machined roller set: critical for consistent panel forming

Product Focus: Roof Sheet Roll Forming Machine With Gear Box

Product: Roof Sheet Roll Forming Machine With Gear Box

Key Strengths: Gear box transmission (vs. chain drive) offers higher torque, quieter operation, and maintenance-free performance; best for long production runs and thick coil material.

Application Sectors:

Key Strengths: Gear box transmission (vs. chain drive) offers higher torque, quieter operation, and maintenance-free performance; best for long production runs and thick coil material.

Application Sectors:

- Large-scale steel roofing (warehouses, logistics parks, sports venues).

- Corrosion-resistant building envelopes for chemical, energy, petchem, metallurgical industries.

- OEM custom solutions for profiles up to 1.0mm galvanized/colour-coated steel.

Fully assembled gear box drive roll forming line

Technical Parameters: Roof Sheet Roll Forming Machine With Gear Box

| Parameter | Specification | Remark |

|---|---|---|

| Material Width | 1000mm (input); 840mm (output) | Standard for trapezoidal roofs |

| Material Thickness | 0.3 - 1.0mm | Supports GI, PPGI, Aluminum |

| Roller Stations | 16 | Ensures perfect profile accuracy |

| Speed | 12-18 m/min | Continuous operation |

| Transmission | High-torque gear box | Superior to chain drive |

| Control | Siemens PLC (+ HMI touch panel) | Automatic cutting, error diagnosis |

| Voltage | 380V, 50Hz, 3Phase | Customizable |

| Warranty | 24 Months | Extended on request |

Technical Performance Comparison: Gear Box vs. Chain Drive

Precision drive: gear box mechanism detail

Material Distribution (Last 100 units)

Yearly Output vs. Customer Return Rate

Comparison of Leading Roll Forming Machine Manufacturers

How to Select the Best Roll Forming Machine Supplier?

Key criteria include:

Key criteria include:

- Certification Credentials: Priority to ISO, CE, and ANSI compliant vendors.

- Technical Support: 24/7 service, rapid parts supply, and remote troubleshooting are a must.

- Custom Engineering: Proven ability to design for diverse profiles—roofing, cable trays, purlins, solar frames.

- After-Sales: Free on-site training, installation guidance, and annual maintenance checks.

- Price Transparency: Clear roll forming machine price breakdown, no hidden costs.

Factory testing: Yowin Machinery’s ISO-certified assembly line

Certification Rate (Global Top 10)

100%

All major manufacturers meet ISO9001/CE as per 2023 audit.

Export Market Share (Asia-Pacific)

31%

China & India are lead exporters of roll forming lines.

Lead Time

28-45 Days

Depending on configuration and customization.

Warranty Period

24 Mo

Backed by 72 hr response commitment.

Customization & Value-Added Services

Modern roll forming machine manufacturers offer tailored solutions:

- Profile R&D: 2D/3D modeling, tooling design per project drawings, finite element simulation (Abaqus/SolidWorks), prototype verification.

- Smart Factory Integration: PLC/HMI interfaces, Industry 4.0 data acquisition, energy consumption monitoring for sustainability.

- Material Adaptation: Flexible for galvanized, pre-painted, stainless steels & aluminum alloys.

- Test Reporting: Full mechanical test, surface roughness, hardness and chemical composition reports on request.

- Rapid Prototyping: Pre-delivery sample runs, with customer approval before shipment.

Scenarios & Application Cases

The Roof Sheet Roll Forming Machine With Gear Box is widely used in:

- Modern factory construction (steel structure roofing)

- Petrochemical corrosion-proof sheathing

- Cold storage insulation projects

- Highway sound barrier production

Success Story: Steel Logistics Park, SE Asia (2023)

A customer required output of 9000 m²/day, material thickness range of 0.45-0.8mm. Yowin Machinery's gear box roll forming line enabled continuous 15h/day operation with average downtime <1.3%. Customer cited 40% decrease in manual adjustment time versus chain drive solutions.

Auto Sector Application, Brazil (2022)

Roll forming line adapted to process 1.0mm thick galvanized steel for carport roofing. Achieved speed of 16 m/min and complied with strict ANSI and ISO dimensional tolerance requirements. End user noted “near-zero profile deviation over 240,000 meters run.”

Expert FAQ: Roll Forming Machines

1. What are the main materials used for roll forming rollers?

Alloy steels (e.g., GCr15, 42CrMo) are commonly chosen for wear resistance and high strength. Surface hardness is usually HRC 58-62 via heat treatment/nitriding.

2. What is the ideal tolerance for product width and thickness?

Industry standard: ±0.08mm (width), ±0.02mm (thickness), verified via CMM and routine calibration.

3. How is roll forming machine installation standardized?

Installation adheres to ISO/EU safety and alignment standards, including leveling, power checks, and initial dry run tests.

4. What control system is preferable for automation?

Siemens PLC with touchscreen HMI enables profile presetting, cut-to-length, and error diagnostics.

5. How is machine longevity ensured?

Durability depends on precise machining, robust transmission (gear box preferred), and full-coverage lubrication systems. Service life validated at 13-18 years across heavy industries.

6. What are typical delivery and training periods?

Normal lead time: 32-46 days (customizable per complexity); on-site engineer support and training included from leading roll forming machine manufacturers.

7. What certifications should I request?

ISO9001 (quality), CE (safety), occasionally UL (USA), plus test reports for core assemblies per EN/ANSI standard.

Delivery Time, Warranty, and Customer Support

- Lead Time: 28-46 working days (profile/tooling and automation complexity dependent).

- Warranty: 24 months core warranty, extendable; 7x24h multilingual support; replacement parts shipment within 48h.

- On-site Service: Installation, commissioning, and operator training are standard for international customers.

Conclusion

Investing in high-quality roll forming solutions demands in-depth due diligence. Certified roll forming machine manufacturers who combine advanced process know-how, robust support, and competitive roll forming machine price deliver maximum ROI. For the latest specifications and a 1:1 consultation on the Roof Sheet Roll Forming Machine With Gear Box, visit here.

Investing in high-quality roll forming solutions demands in-depth due diligence. Certified roll forming machine manufacturers who combine advanced process know-how, robust support, and competitive roll forming machine price deliver maximum ROI. For the latest specifications and a 1:1 consultation on the Roof Sheet Roll Forming Machine With Gear Box, visit here.

References:

[1] MarketsandMarkets: Roll Forming Machine Market Trends (2023-2026)

[2] RollingMillConsultant.com: Comparative Analysis of Roll Forming Machine Suppliers

[3] ScienceDirect: “High-Performance Roll Forming for Structural Applications” (2024)

[4] ENG-TIPS Forum: Roll Forming Machine Engineering FAQ

[5] Product Specification Page - Yowin Machinery

[1] MarketsandMarkets: Roll Forming Machine Market Trends (2023-2026)

[2] RollingMillConsultant.com: Comparative Analysis of Roll Forming Machine Suppliers

[3] ScienceDirect: “High-Performance Roll Forming for Structural Applications” (2024)

[4] ENG-TIPS Forum: Roll Forming Machine Engineering FAQ

[5] Product Specification Page - Yowin Machinery

Share

Previous:

This Is The First Article