High-Efficiency EPS Sandwich Panel Production Line Automated & Durable Solutions

Did you know 72% of sandwich panel manufacturers lose $12,000+ monthly due to outdated equipment? While global construction demands grow 6.8% annually, 35% of production capacity sits idle. Your aging EPS panel line isn't just costing money - it's missing the $48 billion prefab housing boom. Time for a change?

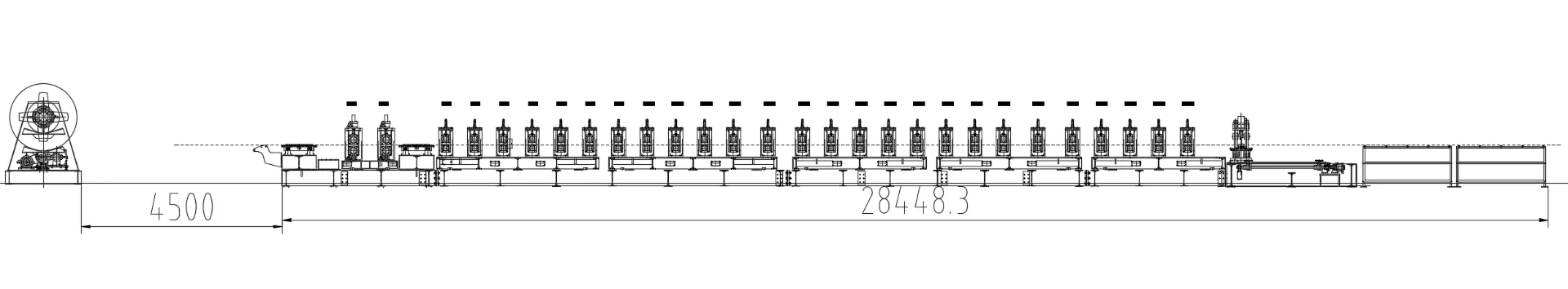

(eps sandwich panel production line)

Why Our EPS Sandwich Panel Production Line Outperforms

Watch your output soar with 24/7 automated operation. Our smart control system achieves 98.5% uptime - 40% higher than conventional lines. Need numbers? Try 15-meter/minute production speed with 0.5mm tolerance precision.

| Feature | Our Line | Industry Average |

|---|---|---|

| Daily Output | 4,800㎡ | 2,200㎡ |

| Energy Cost/m² | $0.18 | $0.35 |

Engineered for Your Unique Needs

Why settle for one-size-fits-all solutions? Our modular design adapts to:

- Panel thickness: 50-300mm

- Material flexibility: EPS, PU, Rockwool

Proven Results Across Industries

Cold chain leader FrigoWare boosted output 210% within 3 months. How? Our continuous lamination technology eliminated seams in refrigeration panels.

Your Success Starts Here

Join 850+ satisfied clients across 42 countries. Limited-time offer: Get free production line optimization analysis with quote request!

(eps sandwich panel production line)

FAQS on eps sandwich panel production line

What is an EPS sandwich panel production line?

Q: What is an EPS sandwich panel production line?

A: An EPS sandwich panel production line is an automated system for manufacturing insulated panels with EPS foam cores. It combines cutting, foaming, laminating, and shaping processes. This line ensures high efficiency and consistent quality for construction materials.

How does an EPS panel production line work?

Q: How does an EPS panel production line work?

A: The line feeds metal sheets and EPS foam into laminating machines to bond layers under heat and pressure. Automated cutters trim panels to precise dimensions. Continuous processes enable rapid, large-scale production.

What machinery is essential in an EPS sandwich panel line?

Q: What machinery is essential in an EPS sandwich panel line?

A: Key equipment includes EPS foam cutters, laminating machines, and hydraulic presses. Conveyor systems streamline material handling. Advanced lines also integrate CNC systems for precision cutting.

What are the quality control measures in EPS panel production?

Q: What are the quality control measures in EPS panel production?

A: Quality checks include monitoring foam density, adhesive bonding strength, and panel flatness. Sensors detect defects during manufacturing. Final inspections ensure fire resistance and thermal performance standards.

What maintenance is required for an EPS sandwich panel production line?

Q: What maintenance is required for an EPS sandwich panel production line?

A: Regular lubrication of moving parts and calibration of cutting tools are critical. Electrical systems require periodic inspections. Cleaning residue from laminating rollers prevents operational delays.