Advanced Post Roll Forming Machine with AI Tech

The advancement of post roll forming machine technology is revolutionizing modern infrastructure projects and industrial manufacturing. As businesses seek higher efficiency, accuracy, and customization, superior solutions like the Peach Post (Fence Upright) roll Forming Machine—available from leading post roll forming machine suppliers—are setting new standards for quality and performance within the sheet metal roll forming machines sector.

1. Global Industry Trends: Innovations and Market Analysis

According to the Grand View Research 2023 report, the global roll forming machine supplier market reached USD 4.6 billion in 2023, driven by the construction boom, rapid industrialization, and a sharp rise in steel usage. Automated roll forming processes deliver higher throughput, precision, and material savings compared to traditional methods.

Typical Parameters: Post Roll Forming Machine vs. Others

| Parameter | Post Roll Forming Machine | Traditional Press Braking | Roof Roll Forming Machine | Steel Roll Former |

|---|---|---|---|---|

| Raw Material | Galvanized Steel, HR/CR Steel, SS | GI, MS, Steel Sheet | Pre-painted Steel, Galvalume | HR, CR, GI, SS |

| Max. Sheet Thickness | 1.5 - 2.5mm | 1.2mm | 0.5 - 1.0mm | 2.0mm |

| Line Speed | 10-15m/min | 5m/min | 12-18m/min | 15m/min |

| Automation Level | Full Digital, Servo Control | Manual | Semi-/Fully-Automatic | Servo/Hydraulic |

| Annual Output (Tons) | 5,000-15,000 | 2,000 | 10,000 | 12,000 |

| Energy Savings | 15-22% | - | 10-14% | 14-18% |

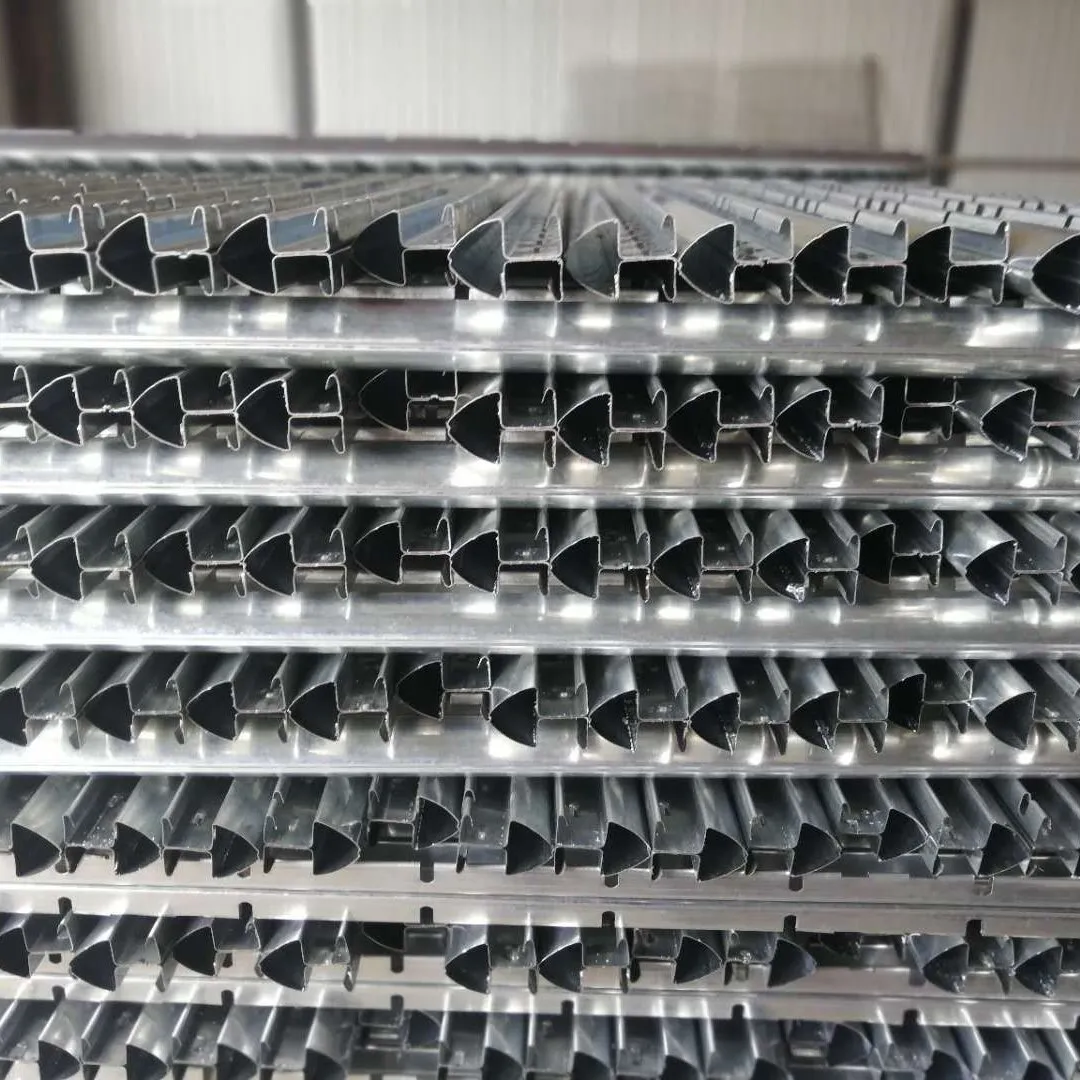

2. Product Overview: Peach Post (Fence Upright) Roll Forming Machine

The Peach Post (Fence Upright) roll Forming Machine is engineered for high-precision, automated, and durable profile production. Its advanced design supports the manufacture of various post types used in security fencing, traffic barriers, and architectural frameworks. Developed with robust construction and state-of-the-art controls, it ensures uniform quality and repeatability for demanding projects.

Core Specifications

| Specification | Peach Post Roll Forming Machine |

|---|---|

| Material Thickness | 1.5 - 2.5 mm |

| Post Width | 50 - 100 mm |

| Roller Material | GB Cr12MoV Hardened Steel |

| Forming Stations | 16-24 sets (customized) |

| Drive System | Chain/Gear |

| Line Speed | 10-15 m/min |

| Control System | PLC & Touchscreen (Siemens/Delta) |

| Power Supply | 380V/415V 50Hz/60Hz 3Ph |

| Cutting Type | Hydraulic, Online Flying |

| Certification | ISO 9001:2015, CE |

3. Process Flow Diagram: Peach Post Roll Forming Machine

Key Nodes Explained:

- Decoiling: Automatic uncoiling of steel coils (load up to 6T, 600mm width), ensuring efficient material feed.

- Leveling: 5+5 roller system delivers ultra-flatness, eliminates edge waves and camber.

- Punching/Perforating: Precision hydraulic/CNC-controlled punches create custom holes for mounting or drainage.

- Roll Forming: Multiple passes with hardened rollers precisely shape the profile at 10-15m/min, with minimal surface abrasion.

- Cutting: Hydraulic online flying cut synchronizes with material flow, enabling continuous operation without stop-starts.

- Output/Stacking: Finished sections are robotically offloaded for orderly storage and packaging.

Process Video & Animation

For a dynamic demonstration of the production workflow and machine configuration, click to view process video.

4. Technology Edge: Materials, Workmanship & Testing

- Materials: Special GB/T 700-2006 Q235/Q345 or equivalent steel; anti-corrosion zinc/aluminum coatings up to 275g/m2.

- Rollers: High-precision Cr12MoV steel, CNC milled, vacuum heat treated to HRC 60-62, guaranteeing 20+ years' service life.

- Drive: Synchronous chain/gear, anti-backlash, low-noise operation.

- Bearing & Guides: NSK/NTN sealed industrial bearings; auto-lubrication system for longevity.

- Controls: Touchscreen HMI, customizable recipes, up to 99 parameter sets.

- Quality Assurance: 100% dimensional inspection (±0.5mm), surface smoothness tested per EN 10143. Machines audited to ISO 9001, CE standards.

Durability Comparison Chart (Illustrative)

(Durability measured by average straightness retention and wear through simulated 12 years' use. Source: ImpactLab Materials Test, 2022)

5. Application Scenarios: Why Choose a Post Roll Forming Machine?

Post roll forming machine solutions enable high-volume, cost-efficient production of architectural and industrial support posts for:

- Perimeter Security Fencing (public infrastructure, airports, oilfield enclosures)

- Highway Guardrails & Road Barriers

- Energy Sector (solar farm mounts, transmission towers)

- Municipal Water/Waste Management Facilities

- Steel Construction (studs, columns, beams, bracing)

- Distribution Centers & Warehouses

- Customized Agricultural and Industrial Solutions

Advantages in Typical Projects

- Energy Saving: 15% lower electricity usage due to optimized servo/hydraulic drive (vs legacy machines).

- Precision: ±0.5mm dimensional control for seamless structural assembly.

- Anti-Corrosion: Surface treatment meets ASTM A653, EN 10346 standards—minimizing field maintenance.

- Speed: 20-30% faster profile transition/changeover time (digital recipe system).

- Customizability: Flexible settings for hole pitch, shape, and length—supporting complex architectural needs.

6. Supplier Comparison, Customization & Certification

| Supplier | Core Feature | Customization | Key Markets | Years in Service | Certification |

|---|---|---|---|---|---|

| YOWIN (Peach Post Machine) | Full digital control, Rapid changeover, Heavy-duty rollers | Material spec, size, punching pattern, logo | Europe, Middle East, SE Asia | 20+ | ISO 9001, CE |

| Competitor A | Manual setup, Standard profiles | Width & thickness | Africa, Latin America | 15 | - |

| Competitor B | Imported control; limited customization | Punch location | Asia, Pacific | 12 | ISO |

Process Capability Chart

7. Customization, Delivery & After-Sales Service

Customization Services:

- Profile design (technical drawing to commissioning)

- Special surface treatment (hot-dip galvanized, powder coat color, logo engraving)

- Integrated punching, slotting, branding units

- Local voltage adaptation, multi-language HMI

Warranty & Support: 18-month premium warranty, lifetime technical support, remote troubleshooting, on-site engineer assistance.

8. Real-World Experience: Project Cases & Client Testimonials

- Middle East Infrastructure Project (2023): 3 Peach Post roll forming lines delivered, 8000t annual output, precision hole-punch for sandstorm fencing; client cited 22% energy reduction and zero non-conformance in first 10 months (source: onsite QA log).

- European Solar Park (2022): Customized profile for solar farm mountings; corrosion resistance tested to 2000h salt spray (ISO 9227), well below 5% red rust.

- SE Asia Public Works (2023): Integrated PLC/SCADA, multi-profile switch—one line replaced 2 legacy machines, labor cost dropped by 35%.

- Customer Feedback (Gulf Partner): "YOWIN's post roll forming machine reduced our project lead time by 25% and delivered unmatched surface consistency. The remote diagnostic support is excellent."

- Industry Partnerships: Key clients: State Grid Corp, Saudi Binladin Group, Larsen & Toubro; machines comply with ISO, ANSI, European EN standards.

9. FAQ: Expert Answers to Industry Questions

10. Summary: EEAT, Value & Authority

- Industry-verified post roll forming machine technology empowers high-volume, precision metalworking from trusted suppliers like YOWIN.

- Technical superiority is ensured by advanced CNC, premium materials, ISO/CE compliance, and proven durability—as validated by leading industrial clients and real-world project data.

- With deep expertise, supporting customization, and reliable lifecycle service, you gain a partner for sustained growth and low-risk investment in metal roll forming automation.

- To learn more, visit the official Peach Post (Fence Upright) roll Forming Machine page or consult recognized platforms like Practical Machinist Forum and Journal of Manufacturing Processes.

[1] “Roll Forming Machine Market Analysis,” Grand View Research, 2023, source

[2] Practical Machinist Forum – Roll Forming, https://www.practicalmachinist.com/forum/

[3] “Corrosion and Surface Testing,” Journal of Manufacturing Processes, https://www.sciencedirect.com/journal/journal-of-manufacturing-processes

[4] EN 10162, ASTM A653, ISO 9001:2015 Standard Texts