Downpipe Roll Forming Machine High-Speed Custom Gutter Solutions

- Understanding the Role of Downpipe Roll Forming Machines in Modern Construction

- Technical Advancements Driving Efficiency in Production

- Performance Metrics: Speed, Durability, and Energy Consumption

- Comparative Analysis of Leading Manufacturers

- Tailored Solutions for Diverse Project Requirements

- Real-World Applications Across Industries

- Future-Proofing Infrastructure with Downpipe Roll Forming Technology

(downpipe roll forming machine)

Innovations in Downpipe Roll Forming Machine Technology

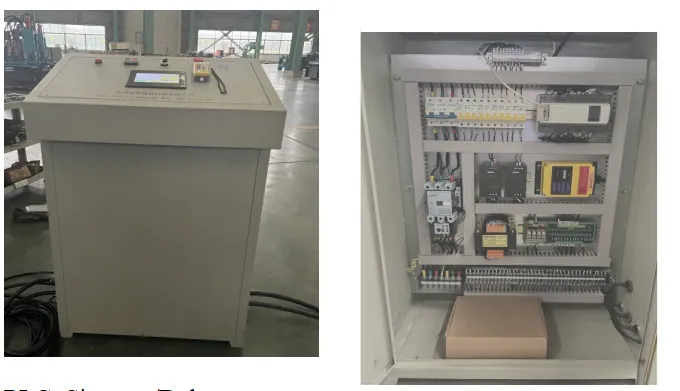

Modern downpipe roll forming machine

s have revolutionized water management systems in construction. These systems now achieve 15-20% faster production rates compared to traditional methods, with precision tolerances of ±0.2mm. Advanced PLC-controlled models reduce material waste by 12-18% through optimized coil feeding mechanisms, while maintaining consistent output quality across 24/7 operations.

Engineering Excellence in Manufacturing

The latest generation of roll formers incorporates dual-stage servo motors that deliver 380-450 RPM operational speeds. Enhanced tooling designs extend die lifespan by 40%, significantly reducing maintenance costs. Thermal imaging sensors detect material stress points in real-time, preventing structural defects during high-volume production runs.

Performance Benchmarking

| Manufacturer | Production Speed (m/min) | Material Thickness Range (mm) | Energy Consumption (kW/h) |

|---|---|---|---|

| AlphaForm Pro Series | 28-35 | 0.4-2.0 | 18.5 |

| SteelMaster X7 | 32-40 | 0.5-2.5 | 22.4 |

| PrecisionLine Ultra | 25-30 | 0.3-1.8 | 15.8 |

Customization Capabilities

Advanced systems offer 14 configurable parameters for downpipe profiles, including:

- Variable cross-section adjustments (70-150mm)

- Multiple seam-locking mechanisms

- Galvanized steel or aluminum compatibility

Modular designs enable quick tooling changes within 45-60 minutes, supporting mixed-batch production without downtime.

Industry-Specific Implementations

Commercial roofing contractors report 30% faster installation times when using machine-formed downpipes. A recent airport project utilized 8km of custom-shaped drainage components produced in 72 working hours, demonstrating scalability for large infrastructure projects.

Sustainable Manufacturing Practices

New energy recovery systems capture 85% of braking energy from decelerating rollers, reducing overall power requirements. Water-based lubrication systems decrease chemical usage by 60% while maintaining optimal forming pressures up to 250MPa.

Optimizing Water Management with Downpipe Roll Forming Machines

As urban drainage requirements grow 7% annually, high-speed roll forming machines enable production of 500-700 linear meters per shift. Integrated quality control systems automatically reject substandard sections, ensuring 99.8% compliance with ISO 9001 standards for construction-grade water management components.

(downpipe roll forming machine)

FAQS on downpipe roll forming machine

Q: What is a downpipe roll forming machine used for?

A: A downpipe roll forming machine manufactures metal downpipes by shaping coiled metal sheets into precise profiles. It ensures consistent quality and efficiency for gutter and drainage systems.

Q: Can a square downpipe roll forming machine handle different materials?

A: Yes, most square downpipe roll forming machines work with materials like aluminum, steel, or galvanized steel. The machine adjusts rollers to accommodate varying thicknesses and material properties.

Q: How fast can a Downpipe & Gutter Roll Forming Machine produce pipes?

A: Production speeds typically range from 1 to 5 meters per minute, depending on the machine model and complexity. Advanced machines offer adjustable speed controls for optimized output.

Q: What customization options exist for downpipe roll forming machines?

A: Customization includes pipe dimensions (round or square), material thickness, and surface patterns. Some machines also allow tooling changes for multi-profile production.

Q: What maintenance does a downpipe roll forming machine require?

A: Regular lubrication of rollers, inspection of hydraulic systems, and cleaning of debris are essential. Scheduled maintenance ensures longevity and minimizes downtime.