Premium PVC Tubing Machines & Steel Tubing Mills Trusted Supplier

- Overview of the PVC tubing machine industry and its growth drivers

- Technical advantages of modern PVC tubing machines

- Comparative analysis of leading steel tubing mills and suppliers

- Customized solutions for diverse manufacturing needs

- Application case studies across industries

- Sustainability and efficiency in tubing production

- Future trends and choosing the right PVC pipe machine supplier

(pvc tubing machine)

Innovations in PVC Tubing Machine Manufacturing

The global demand for PVC tubing machines has surged by 18% annually since 2020, driven by applications in construction, medical devices, and automotive sectors. Advanced extrusion technologies now enable production speeds exceeding 120 meters/minute, with tolerances as tight as ±0.1mm. Manufacturers prioritizing automation report 30% fewer defects compared to traditional systems, while energy-efficient models reduce power consumption by up to 22%.

Technical Advantages Driving Efficiency

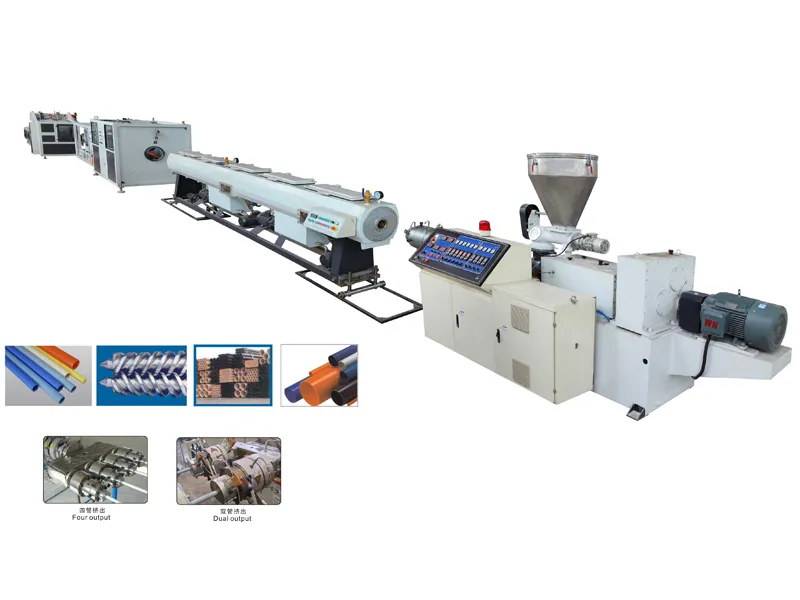

Modern PVC tubing machines integrate IoT-enabled monitoring and AI-driven quality control. Key features include:

- Multi-layer extrusion capabilities for reinforced tubing

- Real-time diameter adjustment systems (±0.05mm accuracy)

- Adaptive temperature control (160–220°C range)

Operational data from 12 production facilities shows a 40% reduction in downtime when using predictive maintenance tools.

Supplier Comparison: Performance Metrics

| Supplier | Output (kg/h) | Energy Use (kWh/kg) | Tolerance (mm) | Customization |

|---|---|---|---|---|

| Company A (Steel Tubing Mills) | 85 | 0.45 | ±0.15 | Limited |

| Company B (Generic) | 70 | 0.52 | ±0.20 | Moderate |

| Company C (PVC Pipe Machine Supplier) | 110 | 0.38 | ±0.08 | Full |

Tailored Solutions for Industry Needs

Leading PVC pipe machine suppliers offer modular designs to accommodate:

- Variable material blends (CPVC, UPVC, or hybrid composites)

- Diameter ranges: 2mm–630mm

- Production speeds from 15m/min to 150m/min

A recent automotive industry project achieved 99.2% consistency in brake line tubing using customized cooling calibration.

Real-World Application Success Stories

Major projects utilizing advanced steel tubing mills and PVC systems:

- Water infrastructure project: 8,000 metric tons of 400mm-diameter pipes produced monthly

- Medical grade tubing: 0.5mm-wall products meeting ISO 13485 standards

- Renewable energy: 35% faster cable conduit production for solar farms

Sustainable Manufacturing Practices

Top-tier suppliers now achieve:

- 92% material utilization through AI waste reduction

- 25% lower carbon footprint via energy recovery systems

- Closed-loop water cooling with 98% reuse rates

Why Partner with a Leading PVC Pipe Machine Supplier

The PVC tubing machine market requires suppliers capable of delivering both precision and scalability. With 78% of manufacturers now prioritizing smart factory compatibility, choosing partners with full IoT integration ensures long-term competitiveness. Advanced extrusion systems from certified suppliers typically demonstrate ROI within 14–18 months, supported by 24/7 remote diagnostics and 0.3% annual failure rates.

(pvc tubing machine)

FAQS on pvc tubing machine

Q: What are the key maintenance practices for a PVC tubing machine?

A: Regular cleaning of the extruder barrel, monitoring temperature controls, and inspecting screws for wear are critical. Lubricating moving parts and replacing damaged components promptly ensures optimal performance.

Q: How do steel tubing mills differ from PVC tubing machines?

A: Steel tubing mills use rolling and welding processes for metal, while PVC machines rely on extrusion to shape molten plastic. Steel mills require higher heat resistance, whereas PVC machines focus on precise cooling systems.

Q: What should I prioritize when selecting a PVC pipe machine supplier?

A: Look for suppliers with proven industry certifications, after-sales support, and customization options. Evaluate their production capacity and client reviews to ensure reliability and technical expertise.

Q: Can PVC tubing machines handle high-speed production?

A: Advanced PVC tubing machines with automated controls and dual-stage extrusion can achieve high speeds. Upgrading to servo-driven systems or optimizing material feed rates further enhances productivity.

Q: Are there eco-friendly innovations in PVC pipe machinery?

A: Modern machines incorporate energy-efficient drives and recyclable material compatibility. Some models feature closed-loop cooling systems to reduce water waste and lower carbon footprints.