Floor Deck Roll Forming Machine-HEBEI YOWIN MACHINERY TECHNOLOGY CO., LTD.|Precision Steel Processing&Industrial Efficiency

Floor Deck Roll Forming Machine: Revolutionizing Steel Deck Production

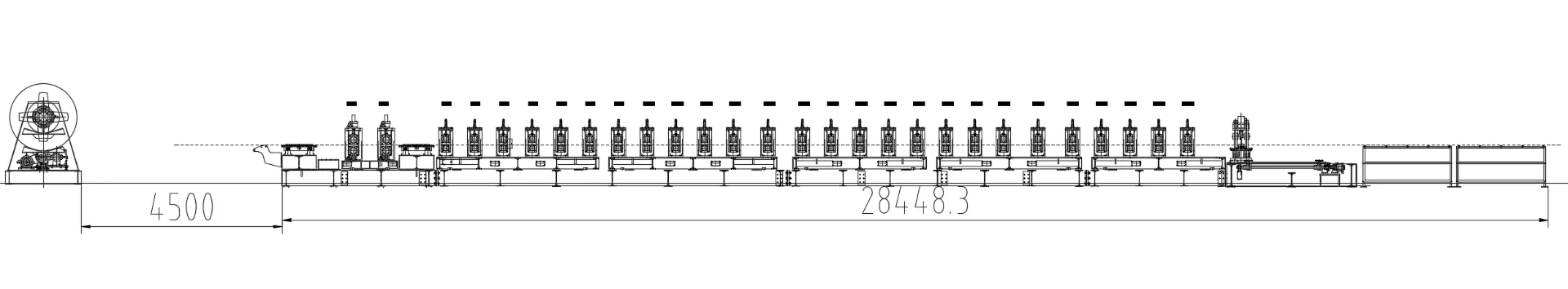

The Floor Deck Roll Forming Machine represents a cutting-edge solution for producing high-precision steel decks used in construction and industrial applications. This advanced machinery combines automated processes with robust engineering to deliver efficient, durable, and cost-effective steel profile production. Developed by HEBEI YOWIN MACHINERY TECHNOLOGY CO., LTD., this system exemplifies modern manufacturing innovation.

Key Features and Technical Specifications

The Floor Deck Roll Forming Machine is designed for precision, efficiency, and durability. Below is a detailed overview of its core components and technical parameters:

| Component | Specification |

|---|---|

| De-coiler | Manual decoiler with 5T bearing capacity, coil width 1250mm, inner diameter 470-560mm, coil diameter 1500mm. Main material: 40Cr. |

| Main Roll Forming Machine | Cast iron memorial archway with gear box. Shaft diameter Φ90, motor power 2x15KW, forming speed 0-20m/min, 25 stations. |

| Hydraulic Cutting System | Hydraulic cutting with Cr12 mould steel blades (HRC58-62). Tolerance: ±1.5mm. |

| PLC Control System | Delta PLC control with touch screen interface. Supports automatic length/quantity measurement and adjustment. |

| Run-out Table | 3m x 2 pieces, angle steel welding with roller support. Passive transmission mode. |

Working Process and Components

The Floor Deck Roll Forming Machine operates through a seamless sequence of processes, ensuring high-quality steel deck production:

- De-coiling: Manual uncoiling system with adjustable feeding rack.

- Roll Forming: 25-station forming with hardened chromium-plated rollers (40Cr quenching and tempering treatment, HB220-260).

- Hydraulic Cutting: Precision cutting with automatic length measurement and adjustable tolerance.

- Control System: PLC-based automation for length/quantity control and real-time adjustments.

- Output: 2-meter run-out tables with passive roller support for smooth material handling.

Technical Parameters

| Parameter | Details |

|---|---|

| Rolling Thickness | 0.6-1.5mm |

| Shaft Diameter | Φ90 |

| Motor Power (Forming) | 2x15KW |

| Forming Speed | 0-20m/min |

| Shear Blade Material | Cr12MOV, HRC58-62 |

| Control System | Delta PLC, touch screen interface |

| Hydraulic System | 5.5KW motor, automatic length measurement |

Applications and Industry Impact

The Floor Deck Roll Forming Machine is widely used in construction, industrial flooring, and infrastructure projects. Its ability to produce precise steel profiles makes it ideal for:

- Residential and commercial building floors

- Industrial warehouses and manufacturing facilities

- Bridge and road construction

- Roofing systems and load-bearing structures

By automating the production of steel decks, this machine reduces labor costs, minimizes material waste, and ensures consistent quality. According to NIST (National Institute of Standards and Technology), such automated systems are critical for advancing manufacturing efficiency and precision in the 21st century.

Company Background: HEBEI YOWIN MACHINERY TECHNOLOGY CO., LTD.

As a leading manufacturer of industrial machinery, HEBEI YOWIN MACHINERY TECHNOLOGY CO., LTD. specializes in designing and producing high-performance roll forming machines. With a focus on innovation and quality, the company has established itself as a trusted partner for businesses worldwide. Their commitment to NIST-aligned standards ensures that their products meet rigorous industry requirements.

The company’s expertise in steel processing machinery is evident in the Floor Deck Roll Forming Machine, which combines advanced engineering with user-friendly automation. This machine exemplifies the company’s dedication to delivering solutions that enhance productivity and reduce operational costs.

Why Choose This Machine?

The Floor Deck Roll Forming Machine offers several advantages that make it a preferred choice for manufacturers:

- High Precision: Advanced PLC control ensures accurate length and quantity measurements.

- Efficiency: 20m/min forming speed reduces production time and increases output.

- Durability: Hardened chromium-plated rollers and Cr12MOV shear blades ensure long-lasting performance.

- Customization: Adjustable feeding system and modular design allow for flexibility in production.

- Cost-Effectiveness: Reduced material waste and labor costs improve overall profitability.

Conclusion

The Floor Deck Roll Forming Machine is a testament to modern engineering excellence. With its advanced features, robust design, and user-friendly automation, this machine sets a new standard for steel deck production. Whether you're involved in construction, manufacturing, or infrastructure development, this system offers the precision and efficiency needed to stay competitive in today's market.

For more information about this product or to explore other solutions from HEBEI YOWIN MACHINERY TECHNOLOGY CO., LTD., visit their official website.

References

National Institute of Standards and Technology (NIST). "Driving Innovation: NIST's Role in Advancing Technology." Retrieved from https://www.nist.gov.