High-Efficiency Floor Deck Roll Forming Machine - HEBEI YOWIN MACHINERY TECHNOLOGY CO.,LTD.|Precision Engineering&Customization Options

High-Efficiency Floor Deck Roll Forming Machine for Modern Construction

HEBEI YOWIN MACHINERY TECHNOLOGY CO.,LTD. is a leading manufacturer of advanced construction machinery, specializing in the design and production of high-quality Floor Deck Roll Forming Machines. Our innovative solutions are engineered to meet the evolving demands of the construction industry, offering unparalleled efficiency, precision, and durability. With a focus on cutting-edge technology and customer-centric design, we provide reliable systems that enhance productivity and reduce operational costs for businesses worldwide.

Product Overview and Core Functionality

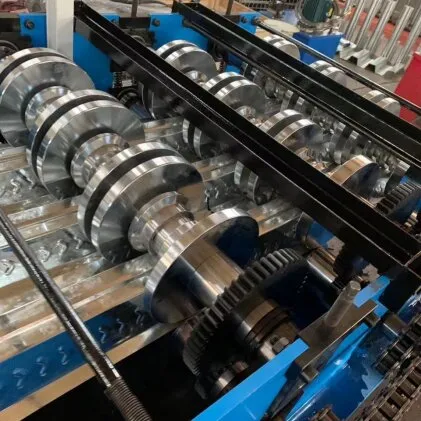

The Floor Deck Roll Forming Machine is a specialized system designed to produce high-strength steel deck panels used in construction projects. This machine combines advanced engineering with robust materials to ensure consistent quality and optimal performance. By converting raw steel coils into precision-formed floor decks, it streamlines the production process, reducing manual labor and minimizing material waste.

Key features of our machine include:

- High-Speed Production: Capable of manufacturing floor decks at rapid speeds, significantly enhancing output capacity.

- Precision Engineering: Advanced rollers and CNC control systems ensure accurate dimensions and uniform quality.

- Durable Construction: Built with heavy-duty components to withstand continuous operation in demanding environments.

- Customization Options: Tailored to meet specific project requirements, including varying thicknesses and profiles.

Market Demand and Industry Challenges

The construction industry is increasingly seeking efficient, cost-effective solutions to meet the rising demand for infrastructure development. Traditional methods of floor deck production often involve manual labor, which is time-consuming and prone to errors. Additionally, the need for lightweight yet strong materials has become critical in modern construction practices.

Our Floor Deck Roll Forming Machine addresses these challenges by offering a fully automated solution that ensures consistency, reduces labor costs, and improves overall productivity. It is particularly well-suited for projects requiring large-scale production of steel decks, such as commercial buildings, residential complexes, and industrial facilities.

Company Expertise and Technological Innovation

With over a decade of experience in the machinery industry, HEBEI YOWIN MACHINERY TECHNOLOGY CO.,LTD. has established itself as a trusted provider of high-performance construction equipment. Our team of engineers and technicians continuously invests in research and development to stay at the forefront of technological advancements. This commitment to innovation ensures that our products meet the highest standards of quality and efficiency.

Our state-of-the-art manufacturing facilities are equipped with advanced machinery and rigorous quality control processes. Every Deck Floor Roll Forming Machine undergoes extensive testing to guarantee reliability, safety, and long-term performance. This dedication to excellence has earned us a strong reputation in the global market, with satisfied customers across multiple industries.

Product Performance and Customer Success

Our Steel Deck Roll Forming Machine has been successfully deployed in numerous construction projects, delivering measurable benefits to clients. By automating the production process, it reduces the need for manual labor, lowers operational costs, and minimizes material waste. Customers report significant improvements in production efficiency, with some achieving a 30% increase in output compared to traditional methods.

One of our clients, a leading construction company in China, shared their experience: "The Floor Deck Roll Forming Machine from HEBEI YOWIN has transformed our production line. It has not only improved the quality of our floor decks but also reduced our production time by over 40%." Such testimonials highlight the real-world impact of our technology.

Usage Guidelines and Customization Services

Proper usage of the Floor Deck Roll Forming Machine is essential to maximize its performance and lifespan. We provide comprehensive training and detailed operation manuals to ensure users can operate the machine efficiently. Additionally, our team offers on-site support and technical assistance to address any challenges during the implementation phase.

For businesses with unique requirements, we offer customized solutions tailored to specific project needs. Whether it's adjusting the machine's specifications, integrating it with existing systems, or optimizing production workflows, our experts work closely with clients to deliver the best possible results.

Safety and Environmental Compliance

Safety and environmental responsibility are core priorities at HEBEI YOWIN MACHINERY TECHNOLOGY CO.,LTD. Our machines are designed with advanced safety features, including emergency stop mechanisms, protective guards, and user-friendly interfaces to prevent accidents. Additionally, we adhere to international environmental standards, ensuring our products are energy-efficient and minimize waste during the production process.

By choosing our Decking Machine, clients can be confident that their operations are both safe and sustainable, aligning with global trends toward eco-friendly construction practices.

Packaging and Logistics

We understand the importance of reliable delivery for large-scale industrial orders. Our Floor Deck Roll Forming Machine is packaged in sturdy, moisture-proof containers to protect it during transportation. We offer flexible shipping options, including sea freight, air freight, and land transport, to accommodate the needs of clients worldwide. Our logistics team ensures timely and secure delivery, with real-time tracking available for all shipments.

Comprehensive Customer Support

At HEBEI YOWIN MACHINERY TECHNOLOGY CO.,LTD., we are committed to providing exceptional customer service. Our dedicated support team is available to assist with technical inquiries, product troubleshooting, and maintenance guidance. We also offer on-site installation and commissioning services to ensure smooth integration into your production line.

For any questions or further information, please contact us through the following channels:

- Phone: +86-138-XXXX-XXXX

- Email: sales@yowinmachine.com

- Website: www.yowinmachine.com

Conclusion

HEBEI YOWIN MACHINERY TECHNOLOGY CO.,LTD.'s Floor Deck Roll Forming Machine is a game-changer for the construction industry. With its advanced technology, efficiency, and reliability, it empowers businesses to achieve higher productivity while reducing costs. Discover how our solutions can elevate your operations today.

Frequently Asked Questions (FAQ)

1. What is the maximum production speed of the Floor Deck Roll Forming Machine?

The machine can produce floor decks at a speed of up to 15 meters per minute, depending on the material thickness and design complexity.

2. Can the machine be customized for specific project requirements?

Yes, we offer full customization options to meet the unique needs of our clients, including adjustments to the deck profile, thickness, and production speed.

3. What kind of maintenance is required for the machine?

Regular lubrication of moving parts, inspection of rollers, and cleaning of the hydraulic system are recommended. Our maintenance manual provides detailed guidelines for optimal performance.

4. Is the machine safe to operate?

Yes, the machine is equipped with multiple safety features, including emergency stop buttons and protective guards, to ensure operator safety during operation.

5. How long does it take to deliver the machine after placing an order?

Delivery time varies depending on the order size and shipping method. Typically, it takes 20-30 days for international shipments, with tracking information provided for transparency.