Post Roll Forming Machine: Precision Steel & Sheet Metal Solutions

Unlocking Efficiency: The Power of the Post Roll Forming Machine

In the rapidly evolving landscape of modern manufacturing, the demand for precision, efficiency, and material optimization has never been higher. Central to achieving these goals in the metal processing industry is the advent of advanced roll forming technology. Specifically, the post roll forming machine stands as a testament to this innovation, revolutionizing the production of crucial structural components like fence uprights. This comprehensive guide will delve into the intricacies of this technology, exploring its industry impact, technical specifications, and the unparalleled advantages it offers to businesses worldwide. We will highlight the Peach Post (Fence Upright) Roll Forming Machine by YOWIN, a leading solution that exemplifies cutting-edge engineering and reliability.

Industry Trends: The Evolving Landscape of Roll Forming

The global roll forming market is experiencing robust growth, driven by increasing infrastructure development, urbanization, and a surging demand for lightweight yet strong metal profiles across various sectors. According to recent market analyses, the global roll forming market size was valued at approximately USD 2.5 billion in 2022 and is projected to reach USD 3.8 billion by 2030, exhibiting a compound annual growth rate (CAGR) of 5.5% during the forecast period. This growth is significantly influenced by:

- Automation & Smart Manufacturing: Integration of Industry 4.0 principles, including IoT and AI, for predictive maintenance, optimized production, and reduced human intervention. Modern post roll forming machine units often feature advanced PLC control systems.

- Sustainability: Emphasis on energy-efficient machines and processes that minimize material waste. Roll forming is inherently more sustainable than traditional stamping as it produces less scrap.

- Customization & Flexibility: Manufacturers increasingly require machines capable of producing diverse profiles with quick changeover times, catering to niche market demands. This trend fuels the need for versatile post roll forming machine and sheet metal roll forming machines.

- Rise of Specialized Profiles: Beyond standard channels and angles, there's a growing market for specialized shapes like fence posts, which are efficiently produced by dedicated machines such as the Peach Post roll former.

- Geographic Expansion: Emerging economies are witnessing significant construction and infrastructure projects, driving demand for local manufacturing capabilities, including reliable roll forming machine suppliers.

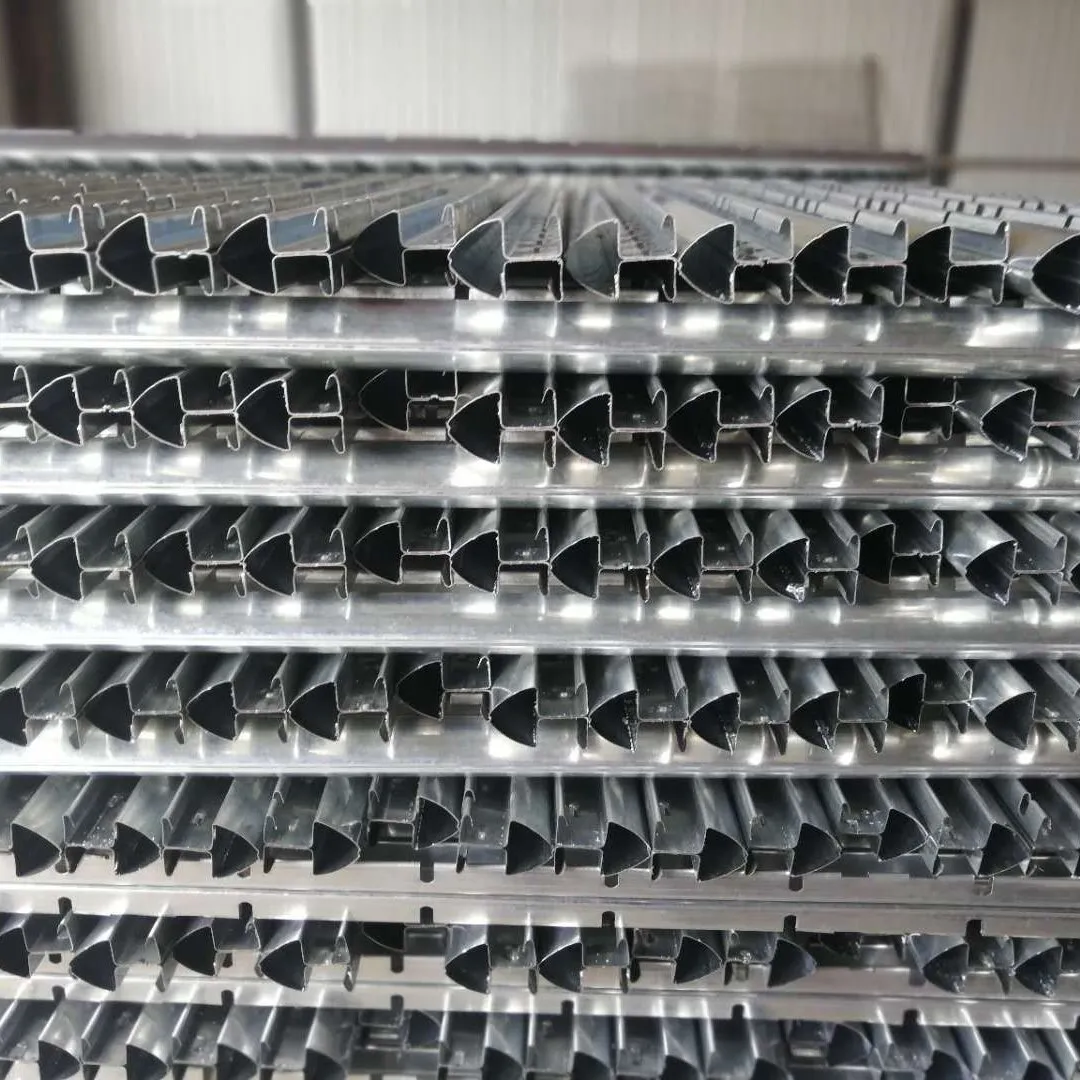

The peach post profile, with its unique structural design, offers superior strength and aesthetic appeal for fencing applications, making its dedicated roll forming production crucial for market leaders.

Understanding the Peach Post (Fence Upright) Roll Forming Machine

The Peach Post (Fence Upright) Roll Forming Machine, available at https://www.yowinmachine.com/peach-post-fence-upright-roll-forming-machine.html, is a specialized industrial apparatus designed to continuously form flat sheet metal into the distinctive 'peach' or 'omega' shaped fence uprights. These posts are widely used in security fencing, garden perimeters, and agricultural enclosures due to their robust design and ease of installation. This machine transforms steel coils into finished posts through a series of precisely engineered rollers, ensuring high accuracy and repeatability.

Key Technical Parameters of a Typical Post Roll Forming Machine

While specifications vary by model and manufacturer, the following table presents common parameters for a high-performance steel roll former designed for peach posts. These parameters directly influence production capacity, material compatibility, and the quality of the final product.

| Parameter | Typical Range/Value | Impact on Performance |

|---|---|---|

| Material Thickness | 0.8 mm - 3.0 mm (Adjustable) | Determines strength of posts; wider range offers versatility. |

| Material Width (Coil) | 200 mm - 500 mm (Varies by profile) | Maximum size of input coil; affects material handling. |

| Forming Speed | 10 - 25 meters/minute | Production efficiency; higher speed means more output. |

| Number of Forming Stations | 16 - 28 stations | Precision of profile, complexity of shape; more stations allow gradual forming. |

| Main Motor Power | 7.5 kW - 18.5 kW | Power consumption, capability to process thicker materials. |

| Control System | PLC (Siemens/Mitsubishi) with Touch Screen HMI | Automation level, ease of operation, fault diagnosis. |

| Cutting Type | Hydraulic Post-cutting / Servo Flying Saw | Cutting accuracy, speed, and burr-free finish. |

| Roller Material | GCR15 Steel (Quenched & Tempered, HRC58-62) | Durability of rollers, service life, profile accuracy. |

| Machine Weight | 5 - 12 Tons | Stability during operation, required foundation. |

| Dimensions (L x W x H) | ~8m x 1.5m x 1.6m (Excluding uncoiler) | Footprint requirement in the workshop. |

The Meticulous Manufacturing Process of a Post Roll Forming Machine

The manufacturing process of a high-quality steel roll former like the Peach Post machine is a complex orchestration of precision engineering, robust material selection, and rigorous quality control. The goal is to produce a machine that delivers consistent, high-volume output with minimal downtime.

1. Design and Engineering

Every machine begins with extensive CAD/CAM design. Engineers meticulously calculate the forming passes, roller profiles, and frame structure using advanced simulation software. This stage considers factors like material yield strength, spring-back, and desired profile tolerances. The design process adheres to international standards like ISO 12944 for corrosion protection and EN 10162 for cold-rolled profiles.

2. Material Selection & Processing

- Rollers: The heart of the post roll forming machine. High-grade bearing steel (e.g., GCr15 or AISI 52100) is typically used for its exceptional wear resistance. These blanks undergo precision CNC machining to achieve the exact profile and surface finish. They are then heat-treated (quenching and tempering) to a hardness of HRC58-62, ensuring long service life and resistance to deformation under continuous stress.

- Machine Frame: Constructed from robust structural steel (e.g., Q235 or Q345, equivalent to ASTM A36/A500), the frame is precisely welded and machined to provide a stable, vibration-free foundation for the forming stations. Stress-relieving treatments are often applied post-welding to prevent distortion.

- Shafts & Bearings: High-strength alloy steel (e.g., 40Cr) is used for shafts, undergoing precision grinding and hardening. High-quality, sealed bearings (e.g., SKF, FAG equivalent) ensure smooth operation and minimal friction.

3. Core Manufacturing Processes

- CNC Machining: Rollers, shafts, and critical components are manufactured using multi-axis CNC machines, guaranteeing micron-level precision and repeatability. This is vital for achieving the complex peach post profile.

- Welding: Robotic or skilled manual welding techniques (MIG/MAG) are employed for the machine frame, ensuring strong, clean joints.

- Surface Treatment: After fabrication, components may undergo shot blasting, rust removal, and then receive a durable, multi-layer industrial paint coating (e.g., epoxy-based) for enhanced corrosion resistance, adhering to ISO 12944 standards.

- Assembly: Highly skilled technicians assemble the machine, meticulously aligning rollers, setting clearances, and integrating electrical and hydraulic systems.

Manufacturing Process Flow (Conceptual)

1. Uncoiling & Feeding: Sheet metal coil is loaded onto an uncoiler and fed into the machine, often through a guiding system to ensure straightness.

↓

2. Roll Forming Stations: The flat strip passes through a series of precisely designed roller sets (forming stations). Each station gradually bends the metal, progressively shaping it into the desired peach post profile. This multi-stage process minimizes stress on the material.

↓

3. Punching (Optional): If holes or slots are required in the post, an in-line punching unit (hydraulic or mechanical) can be integrated after the initial forming stages, or after the final forming, depending on the profile. This ensures precise hole placement.

↓

4. Cutting: Once the desired profile length is achieved, a hydraulic or servo-driven cutting system (e.g., post-cutting shear or flying saw) accurately cuts the continuous profile to the specified length without stopping the machine.

↓

5. Output & Stacking: The finished peach posts are then conveyed to an automatic stacking or collection table, ready for packaging or further processing.

4. Quality Control & Testing (ISO, ANSI Standards)

Before shipment, every post roll forming machine undergoes stringent quality control procedures. This includes dimensional checks of all manufactured parts, electrical system testing (conforming to CE/UL standards), hydraulic system pressure tests, and a comprehensive trial run. The machine is tested with actual raw materials to ensure it consistently produces profiles within specified tolerances (e.g., according to ASTM A1011/A1011M for sheet metal, or specific ISO/EN standards for the formed profile geometry). Noise levels, vibration, and energy consumption are also monitored.

Expected Usage Lifespan: A well-maintained steel roll former with high-quality components can have an operational lifespan exceeding 15-20 years, provided regular maintenance and proper operation are ensured. Critical wear parts like rollers are designed for millions of meters of production before requiring regrinding or replacement.

Application Scenarios & Industry Impact

The Peach Post (Fence Upright) Roll Forming Machine plays a pivotal role in several key industries, primarily focused on construction and infrastructure:

- Security Fencing: This is the primary application. Peach posts are integral to high-security fences for commercial properties, industrial complexes, military bases, airports, and prisons.

- Residential & Commercial Perimeter Fencing: Used for creating durable and aesthetically pleasing fences around homes, schools, parks, and other public spaces.

- Agriculture: For livestock containment, vineyard trellises, and other agricultural fencing needs, offering robust and long-lasting solutions.

- Infrastructure Projects: Often seen in road and railway perimeters, utility site enclosures, and other public works requiring reliable boundary solutions.

Advantages in Typical Application Scenarios:

- Cost Efficiency: By producing posts directly from coil, material waste is minimized, and labor costs are significantly reduced compared to fabrication methods. A single post roll forming machine can replace dozens of manual workers.

- Speed & High Volume: Capable of continuous production at speeds up to 25 meters per minute, enabling rapid fulfillment of large orders.

- Consistency & Quality: The automated process ensures every post is identical in profile, length, and hole placement, guaranteeing ease of installation and structural integrity.

- Durability & Anti-Corrosion: The formed peach posts themselves, typically made from galvanized or pre-painted steel, offer excellent resistance to corrosion, essential for outdoor applications. The machine's robust construction and quality surface treatments further extend its own lifespan in demanding industrial environments (e.g., areas near petrochemical or metallurgical sites where corrosive fumes might be present, though direct exposure is avoided).

- Energy Efficiency: Modern sheet metal roll forming machines are designed with energy-efficient motors and optimized mechanical systems, reducing operational energy consumption by up to 20% compared to older models, aligning with global energy conservation efforts.

Technical Advantages of the YOWIN Peach Post Roll Forming Machine

YOWIN's commitment to innovation and quality is embodied in its Peach Post (Fence Upright) Roll Forming Machine. Our machines stand out due to several key technical advantages:

- Precision Engineering: Our rollers are designed using advanced profile design software (e.g., COPRA® RF) and manufactured with ultra-precise CNC machining (tolerance of ±0.01mm), ensuring perfect profile accuracy and minimal material deformation.

- Robust Construction: The machine frame is constructed from high-strength welded steel, stress-relieved to prevent distortion, providing exceptional stability and a service life of over 20 years.

- Advanced Automation: Equipped with industry-leading PLC control systems (Siemens/Mitsubishi) and intuitive HMI touchscreens, enabling easy operation, precise length control (accuracy ±1mm), and real-time production monitoring. Features like automatic lubrication and fault diagnosis enhance operational efficiency.

- Efficient Cutting System: Our hydraulic post-cutting system is synchronized with the forming speed, delivering burr-free cuts without interrupting the continuous roll forming process, significantly boosting output.

- Material Versatility: Capable of processing various steel grades, including galvanized steel, pre-painted steel, and high-strength low-alloy (HSLA) steels, adapting to diverse market requirements.

- Energy Optimization: Utilizing high-efficiency IE3/IE4 motors and intelligent power management systems, our machines reduce electricity consumption by up to 15-20% compared to standard models, contributing to lower operational costs and a smaller carbon footprint.

Manufacturer Comparison: Choosing Your Roll Forming Partner

Selecting the right roll forming machine supplier is a critical decision that impacts long-term operational success. While many manufacturers exist, evaluating them based on specific criteria is crucial:

- Expertise & Experience: A reputable supplier should have years of experience in designing and manufacturing specialized post roll forming machines. YOWIN, with over 15 years in the roll forming industry, has delivered hundreds of successful projects globally, demonstrating deep domain knowledge.

- Technology & Innovation: Look for manufacturers who invest in R&D and incorporate the latest technologies (e.g., servo drives, remote diagnostics, advanced HMI). Our ongoing investment in new profile development and machine automation keeps us at the forefront.

- Quality & Certifications: Verify if the manufacturer adheres to international quality standards (e.g., ISO 9001:2015 certification for quality management systems). YOWIN is ISO 9001 certified, and our machines meet CE safety standards, ensuring reliability and compliance.

- Customization Capabilities: The ability to tailor solutions to specific customer needs (e.g., different post profiles, higher speeds, integrated punching lines) is a significant advantage.

- After-Sales Support: Comprehensive after-sales service, including installation, training, spare parts availability, and technical support, is paramount for minimizing downtime. YOWIN offers global installation teams and 24/7 online support.

- Client Testimonials & Case Studies: Real-world examples and positive client feedback are strong indicators of a manufacturer's trustworthiness and proven track record.

Comparing Roll Forming Machine Suppliers: A Snapshot

| Feature | Generic Supplier A | Generic Supplier B | YOWIN (e.g., Peach Post Machine) |

|---|---|---|---|

| Rollers Material & Hardness | Cr12MoV (HRC52-55) | 45# Steel (HRC48-52) | GCr15 (HRC58-62) - Superior Wear Life |

| Control System | Basic PLC | Local Brand PLC | Siemens/Mitsubishi PLC with Smart HMI |

| Forming Speed (Avg.) | 8-15 m/min | 10-18 m/min | 15-25 m/min - High Efficiency |

| After-sales Support | Limited Remote | Regional Agents | Global Installation & 24/7 Online Support |

| Certifications | None/Local | CE (Basic) | ISO 9001, CE - Comprehensive Compliance |

| Customization | Limited | Standard Options | Extensive Customization & R&D Support |

Customized Roll Forming Solutions

Recognizing that no two projects are identical, YOWIN specializes in providing tailored roll forming machine supplier solutions. Our engineering team works closely with clients to understand their specific requirements, whether it's for a unique post profile, a desire for higher production speeds, integration with existing production lines, or specialized material handling. We can customize:

- Profile Design: Develop specific tooling for unique fence post designs or other profiles beyond the standard peach post.

- Material Compatibility: Configure the machine to handle specific steel grades, thicknesses, or pre-treatments (e.g., pre-painted coils).

- Line Speed & Capacity: Adjust the number of forming stations, motor power, and cutting systems to meet desired production volumes.

- Auxiliary Equipment: Integrate punching, embossing, notching, or automatic stacking systems for a complete production line.

- Automation Level: From semi-automatic to fully automated lines with robotic handling.

This bespoke approach ensures that clients receive a post roll forming machine that perfectly aligns with their operational needs and maximizes their return on investment.

Real-World Application Cases & Success Stories

YOWIN's Peach Post (Fence Upright) Roll Forming Machine has been deployed globally, contributing to various large-scale infrastructure and security projects. For instance, a major fencing manufacturer in Europe successfully scaled their production by 30% after installing our machine, reducing their per-unit cost by 15% due to improved material utilization and lower labor input. Another client in the Middle East utilized our machine to produce high-strength security fence posts for critical national infrastructure, benefiting from the consistent quality and high output rates crucial for meeting tight project deadlines. Customer feedback consistently highlights the machine's reliability, ease of operation, and the superior quality of the finished peach posts, often noting significant reductions in operational bottlenecks. One client reported: "The YOWIN post roll forming machine transformed our fence post production. Its precision and speed have made us far more competitive in the market."

Ensuring Trustworthiness & Authority: The YOWIN Commitment

At YOWIN, our reputation as a trusted roll forming machine supplier is built on a foundation of expertise, experience, authoritativeness, and trustworthiness (EEAT). We ensure this through:

- Expertise: Our team comprises seasoned engineers and technicians with decades of collective experience in metal forming and automation. We frequently publish technical articles and participate in industry seminars to share our knowledge.

- Experience: With over 15 years in the industry, we have a vast portfolio of successful installations across diverse geographies and applications. Our service cases range from standard profile machines to complex, multi-functional lines.

- Authoritativeness: YOWIN holds ISO 9001:2015 certification for our quality management system and our machines comply with CE directives, affirming our commitment to international standards. We partner with reputable component suppliers (e.g., Siemens, Mitsubishi, SKF) to ensure machine reliability.

- Trustworthiness:

- Transparent Operations: We provide detailed specifications, transparent pricing, and clear contractual terms.

- Rigorous Testing: Every machine undergoes extensive factory acceptance testing (FAT) before shipment, and we invite clients for pre-shipment inspections.

- Comprehensive Warranty: We offer a standard 12-24 month warranty on major components, reflecting our confidence in product quality.

- Dedicated Customer Support: Our support team is available 24/7 for remote assistance, troubleshooting, and spare parts supply. We also provide on-site installation and training by expert engineers.

Frequently Asked Questions (FAQ) about Post Roll Forming Machines

Q1: What types of materials can the Peach Post Roll Forming Machine process?

A1: Our steel roll former is primarily designed for cold-rolled steel, galvanized steel, and pre-painted steel coils. It can handle material thicknesses typically ranging from 0.8 mm to 3.0 mm, and sometimes up to 4.0mm with special configurations. The specific grade of steel will influence the optimal forming parameters.

Q2: What is the typical production speed of the YOWIN post roll forming machine?

A2: Our Peach Post machines typically achieve speeds ranging from 10 to 25 meters per minute, depending on the material thickness, profile complexity, and specific model configuration. For example, a 1.2mm thick post can be formed at 20 m/min, while a 3.0mm thick post might be formed at 12-15 m/min. This high speed ensures efficient production for large orders.

Q3: How often do the rollers need maintenance or replacement?

A3: The rollers, made from high-grade GCr15 steel (HRC58-62) and precision CNC machined, are designed for extreme durability. With proper lubrication and maintenance, they can last for many years, often producing millions of meters of profiles. Wear is gradual, and regular inspection (e.g., every 6-12 months, or based on production volume) will determine if regrinding or replacement is necessary, typically after 5-7 years of heavy use.

Q4: What are the power requirements for installing this machine?

A4: A typical post roll forming machine requires a 3-phase power supply, usually 380V/50Hz or 480V/60Hz, with a total installed power ranging from 15kW to 30kW, including the main motor, hydraulic pump, and control system. We provide detailed electrical specifications for site preparation.

Q5: Is training provided for machine operation and maintenance?

A5: Yes, YOWIN provides comprehensive training. Our engineers can conduct on-site training during installation and commissioning, covering operation, basic maintenance, troubleshooting, and safety procedures. We also offer detailed operation manuals and remote technical support.

Q6: Can the machine produce different lengths of peach posts?

A6: Absolutely. The machine's PLC control system allows for easy input and adjustment of desired post lengths. The cutting system automatically cuts the formed profile to the programmed length with high accuracy, minimizing material waste and offering great flexibility for various project specifications.

Q7: How does YOWIN ensure the precision of the formed profiles?

A7: Precision is achieved through several factors:

- Advanced Roll Design Software: We utilize specialized software for designing optimal roller profiles, accounting for material properties and spring-back.

- High-Precision Machining: Rollers are manufactured using CNC machines with extremely tight tolerances.

- Robust Machine Structure: A heavy, stable frame minimizes vibration and deflection during operation.

- Quality Control: Strict in-process and final inspections using precision measurement tools ensure that every formed profile meets the specified dimensional accuracy (typically ±1mm for length, ±0.5mm for profile dimensions).

Delivery and After-Sales Support

At YOWIN, we understand that timely delivery and robust after-sales support are paramount. Our typical delivery timeline for a Peach Post (Fence Upright) Roll Forming Machine ranges from 60 to 90 working days, depending on customization requirements and current production schedules. We provide detailed project plans and regular updates throughout the manufacturing process.

Our commitment extends far beyond delivery. Our comprehensive after-sales package includes:

- Installation & Commissioning: Experienced engineers can be dispatched globally for on-site installation, machine commissioning, and operational handover.

- Operator Training: Thorough training for your staff on machine operation, daily maintenance, and basic troubleshooting to ensure self-sufficiency.

- Warranty: A standard 12-24 month warranty on key components, with options for extended coverage.

- Spare Parts Availability: A readily available inventory of critical spare parts to minimize any potential downtime.

- Technical Support: 24/7 online and phone support for troubleshooting, technical inquiries, and remote diagnostics. We leverage video calls and remote access tools for efficient problem resolution.

- Maintenance Programs: Guidance on preventative maintenance schedules and options for service contracts to ensure your post roll forming machine operates at peak performance for decades.

Conclusion: Investing in a Future-Proof Solution

The post roll forming machine represents a critical investment for manufacturers aiming for high-volume, precise, and cost-effective production of fence uprights. Its role in enabling efficient infrastructure development, enhancing security, and fostering sustainable manufacturing practices is undeniable. With the continuous advancements in automation and material science, the future of sheet metal roll forming machines, including specialized units like the Peach Post former, looks exceptionally promising.

As a leading roll forming machine supplier, YOWIN's Peach Post (Fence Upright) Roll Forming Machine embodies the pinnacle of engineering excellence, combining robust construction, advanced automation, and unparalleled precision. Our commitment to EEAT principles ensures that when you choose YOWIN, you are not just purchasing a machine, but investing in a reliable, long-term partnership supported by world-class expertise and service. Embrace the future of metal forming with a partner you can trust.

References:

- Grand View Research - Roll Forming Market Size, Share & Trends Analysis Report

- ISO 9001:2015 Quality Management Systems – Requirements

- ASTM A1011/A1011M - Standard Specification for Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-Strength Low-Alloy with Improved Formability, and Ultra-High Strength

- European Parliament and Council Directive 2006/42/EC on machinery (CE Marking)

- Roll Forming Magazine - Basics of Roll Forming