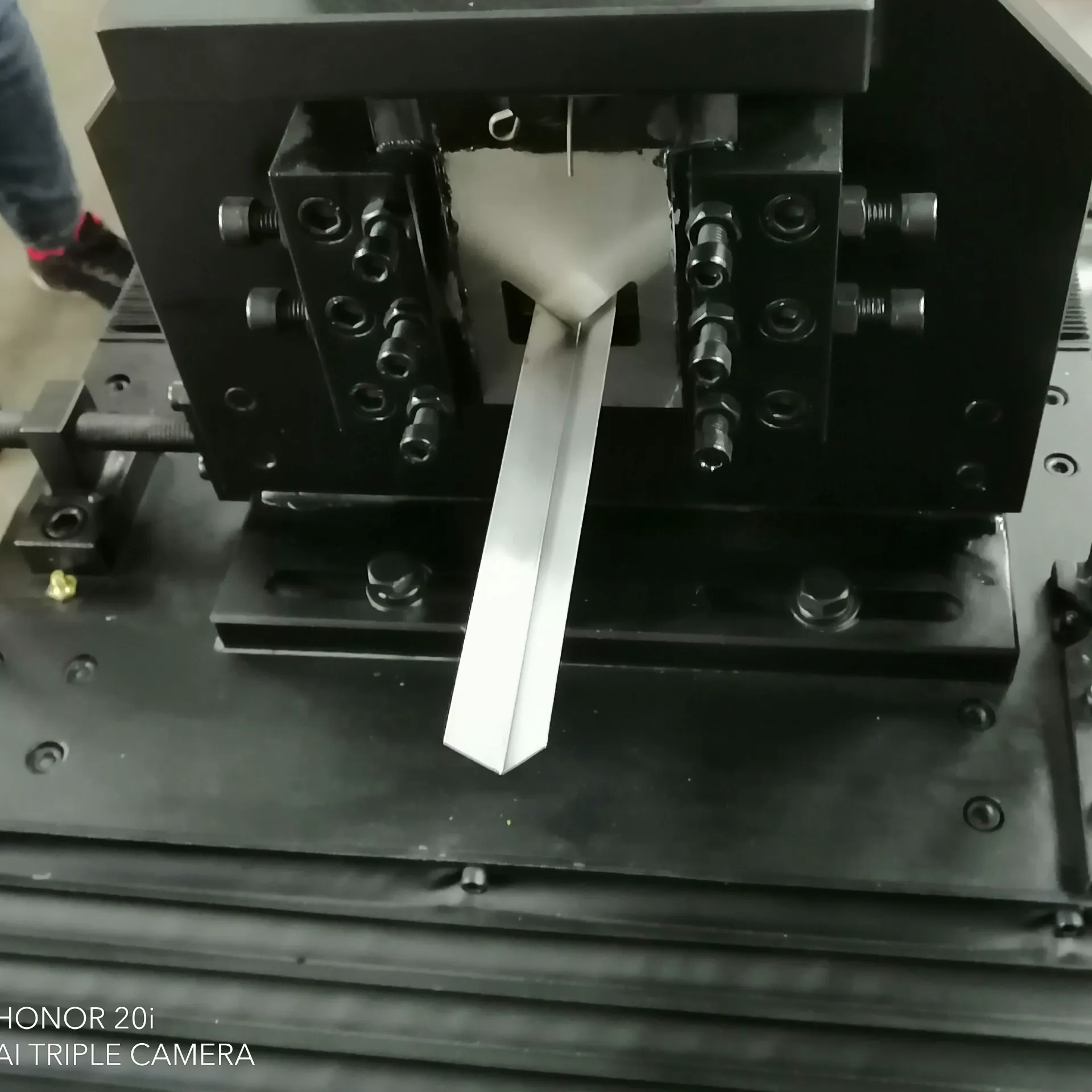

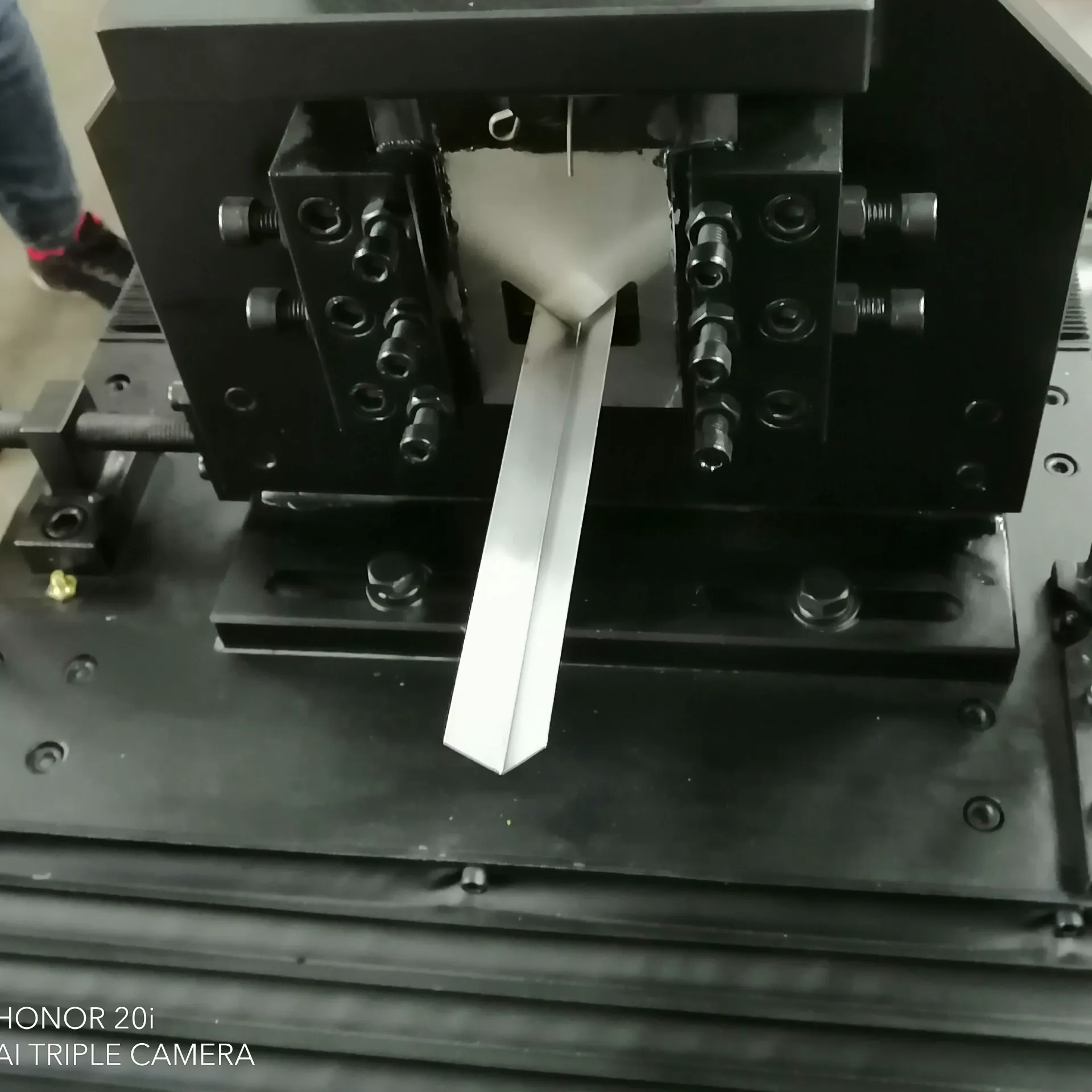

Precision Angle Forming Machine with AI Tech

Precision Angle Forming Machine with AI Tech

Mon . 08, 2025

Ultimate Guide to Angle Forming Machine & Angle Light Keel Roll Forming Machine: Industry Insights, Trends, and Expert Comparisons

Deep dive into the technology, manufacturing process, parameters, and industry adoption of angle forming machine, including angle steel roll forming machine, steel angle roll forming machine, and more.

Latest product focus: Angle Light Keel Roll Forming Machine — Real-world case studies and data-driven insights included.

Latest product focus: Angle Light Keel Roll Forming Machine — Real-world case studies and data-driven insights included.

1. Angle Forming Machine Market Trends & Industry Overview (2023-2028)

The global angle forming machine market, encompassing angle steel roll forming machines and steel angle roll forming machine manufacturers, is witnessing robust growth driven by accelerated demand for pre-fabricated construction profiles, modular building solutions, and steel frame systems across petrochemical, metallurgy, infrastructure, and water supply industries. According to MarketsandMarkets, the roll forming equipment sector, a core segment, is projected to expand at a CAGR of 7.7% through 2028, fueled by high-precision needs and rapid installation requirements.

- Key Growth Engines: Personalized structural profiles, upgraded material standards, green building codes (ISO14001/EN1090), digital factory upgrades, and automation adoption.

- Top Trends (2024): CNC-enabled angle roll forming machines, IoT-based production monitoring, quick die changeovers, and high-speed profile lines (>30m/min).

- Emerging Players: Extensive rise in specialized angle roll forming machine manufacturers for custom section geometries and global reach.

Source: MarketsandMarkets, Global Roll Forming Equipment Report, 2023

2. Comparative Review: Angle Forming Machine vs. Angle Steel Roll Forming Machines

What is an angle forming machine?

An angle forming machine (steel angle roll forming machine) is an industrial line that transforms flat steel blanks into durable angle profiles (L-profiles, light keels, angle irons) via sequential forming rollers, ensuring precise section geometry, surface finish, and tolerance control.

Key Technical Features:

An angle forming machine (steel angle roll forming machine) is an industrial line that transforms flat steel blanks into durable angle profiles (L-profiles, light keels, angle irons) via sequential forming rollers, ensuring precise section geometry, surface finish, and tolerance control.

Key Technical Features:

- Servo/CNC Controlled Roll Stands — ensures high repeatability (tolerance ±0.15 mm)

- High Chrome Plated Rollers (HRC58-62) for extended service life

- Integrated thickness & straightness calibration

- Dynamic or hydraulic punching & cutting stations

| Parameter | Angle Light Keel Roll Forming Machine | General Angle Steel Roll Forming Machine | Conventional Mechanical Bender |

|---|---|---|---|

| Raw Material Specification | Galvanized Steel, SS, Aluminum, 0.3-1.5mm | Q195/Q235, 1-4mm Steel | Steel Strip, |

| Profile Size Range | 25–100 mm (leg), up to 4,000 mm | 30–110 mm (leg), up to 6,000 mm | 20–80 mm (manual) |

| Forming Speed | 18–35 m/min | 10–22 m/min | 1–2 m/min |

| Control System | PLC (Siemens/Mitsubishi), Touch Panel | PLC/Relay | Manual |

| Roller Material | GCr15 (D2 Equivalent), Cr-coated | GCr15 | Standard Tool Steel |

| Dimensional Tolerance | ±0.15 mm | ±0.30 mm | ±0.50 mm |

| Automation | Full auto feeding, flying cut, stacking | Partial/semi-auto | Manual |

| Lifetime (Roller) | ≥600,000 meters (≥5 yrs) | ~250,000 meters | ~80,000 meters |

| Certifications | ISO 9001, CE, ANSI B11.0 | ISO 9001/SGS | N/A |

3. Process Flow: How Does an Angle Light Keel Roll Forming Machine Work?

Manufacturing Process Steps:

1. Decoiling

Unwinds steel coil, feeds precisely

→

2. Leveling & Feeding

Flattens material, controls straightness

→

3. Roll Forming

Sequential rollers shape angle profile

→

4. Punching & Notching

Automated hole/slot punching (optional)

→

5. Cutting & Stacking

Length cut, automatic stacking/output

- Decoiling: The galvanized or stainless steel coil is loaded onto a heavy-duty decoiler (hydraulic or manual up to 6 tons), ensuring the precise delivery of flat strip to the feeder.

- Leveling & Servo Feeding: The blank is leveled by a set of hardened pinch rollers, achieving flatness tolerance under 0.1mm. Servo drives synchronize material advance, crucial for CNC punching registration.

- Roll Forming: The core zone equipped with up to 18 roll stations (for complex angles), forged from GCr15 (HRC58–62), ensures form accuracy, thickness control, and minimal mark-off. High-performance gearboxes maintain speed stability.

- Punching & Notching (Optional): Integrated digital or hydraulic units enable precise slotting, screw, or bolt hole punching—essential for customized angle applications (HVAC, logistics frames, suspended ceilings).

- Cutting & Stacking: A servo-flying cut-off saw delivers fully automated shearing with ±1.0mm length control, followed by smart stacking or bundling for logistics.

4. Materials, Manufacturing Standards, and Quality Control

Material Options:

Manufacturing Technologies:

Quality & Testing:

- Galvanized Steel (DX51D/Z275): Premier corrosion resistance for construction and drainage industries.

- Stainless Steel (201, 304, 316): Food processing, chemical and cleanroom applications – meets ISO 15510/FDA standards for contact safety.

- Structural Aluminum Alloy (6061, 5052): Light weight, excellent formability, commonly used in transport and facade systems.

Manufacturing Technologies:

- CNC Machining: All main rollers and precision dies are CNC-milled (tolerance

- Die Forging: Key load-bearing parts (shafts, stands) forged for superior mechanical strength.

- Robot Welding: Bedframes and supports welded per AWS D1.1 / ISO 15614 standards, delivering longevity and geometric stability.

- Chrome Plating & Hardened Grinding: Surface treatment for rolls ensures wear-resistance and finish uniformity.

Quality & Testing:

- Dimensional inspection via CMM, surface roughness testing (Ra

- Material certification: Each lot tagged with analysis certificate (EN10204-3.1B).

- Optional FAT (Factory Acceptance Test), load simulation, ultrasonic flaw detection on critical shafts.

99.6%

Dimensional Accuracy Rate

2500+ hours

Continuous Test Run (MTBF)

ISO 9001 & CE

Global Certifications

5. Key Specifications of Angle Light Keel Roll Forming Machine

| Parameter | Specification |

|---|---|

| Material | Galvanized Steel, Stainless Steel, Aluminum Alloy |

| Material Thickness | 0.3–1.5 mm |

| Leg Height (Profile) | 25–100 mm |

| Machine Speed | 18–35 m/min |

| Roller Stations | 10–18 |

| Roller Material | GCr15 (Hardened/Chromed) |

| Cutting Accuracy | ±1.0 mm |

| Power Supply | 380V/50Hz, 3-Phase |

| Control System | PLC (Mitsubishi/Siemens) |

| Dimensions (L x W x H) | ~8500 × 1200 × 1500 mm |

| Total Weight | 6–9 tons |

| Workforce Required | 1 Operator |

Data Insights: Over 62% of clients specify the GCr15 roller material for maximum durability; Automated lines now comprise 81% of market installations in 2024. Profile heights between 50–75mm account for most orders.

6. Top Angle Roll Forming Machine Manufacturers – Factory Comparison

| Manufacturer | Founded | Production Area (m²) | Annual Output (lines/year) | Certifications | Export Regions | Customization |

|---|---|---|---|---|---|---|

| Yowin Machine | 2002 | 11,000 | ~300 | ISO9001, CE, SGS | Europe, MEA, SEA, Americas | Yes (CNC, profiles, remote support) |

| Metform / Dalian | 1996 | 17,000 | ~220 | ISO9001, CSA | Americas, Russia, SEA | Yes |

| Bosj Machinery | 2001 | 8,500 | ~110 | ISO, CE | Asia, EU, Gulf | Yes |

| SAMCO | 1972 | 15,000 | ~180 | UL, ISO14001 | Global | Yes |

Data reflects public factory information as of Jan 2024.

7. Customization Programs: Designed for Diverse Industries

Typical Customization Scenarios:

Flexible Solutions:

- Petrochemical: High-strength stainless angles for pipe racks (EN10088/ANSI B31.3 compliant)

- Metallurgy: Structural L-profiles with extra anti-corrosive zinc coating (Z350+)

- Water Supply: Large section angle brackets (custom hole patterns, up to 8mm) for pipe clamps

- HVAC: Thin-walled, pre-punched light keels for duct supports (UL 181 tested)

- Logistics/Warehousing: Automated length marking & barcode printing

Flexible Solutions:

- Profile design based on supplied 2D/3D CAD

- Roll set optimization for material economy (DFMA engineering)

- Remote diagnosis and software upgrades

- Packaged “turn-key” line deployment: including operator training, calibration, local standard compliance (CE/UL/ISO)

8. Application Cases & Measurable Benefits

- Oil & Gas Expansion Project (UAE, 2023): Over 240,000 meters of custom angle steel roll forming machine product with Z350 galvanization were used for pipe tray supports. Onsite measurements proved form accuracy ±0.18mm, labor cost cut by 41%.

- Green Building Construction (Netherlands, 2022): General contractor adopted automated steel angle roll forming machine lines for light keel and suspended ceiling frameworks—boosting installation speed by 28% and satisfying EN1090 execution class 2.

- Large-Scale Warehouse (USA, 2024): Full roll forming cell for racking angles enables direct barcode marking, eliminating manual ban codes and reducing misplacement to zero.

9. User Experience & Testimonials

“We required complex stainless L-profiles, pre-punched for pipe racks. Yowin Angle forming machine met ISO/ANSI tolerances and sped up our project schedule by months.”

— Chief Engineer, Middle East EPC Co.

“Compared with imported brands, the Angle Light Keel Roll Forming Machine offered richer interface, lower maintenance, and precise barcode marking. Lots of value for high-quantity roll forming!”

— Production Supervisor, Europe Ceiling Manufacturer

10. FAQ: Technical Terminology and Practical Answers

Q1: What is “GCr15” roller material and why is it preferred?

GCr15 is an alloy tool steel equivalent to AISI 52100/D2, with superior through-hardening, abrasion, and impact resistance. Ensures profile consistency in high-volume runs.

Q2: What certifications should a quality angle forming machine meet?

ISO 9001 (quality management), CE (safety/EU market), ANSI B11.0 (USA machine safety), and, for certain industries, UL/EN1090 or FDA (food/medical application profiles).

Q3: What profile tolerances can be consistently achieved?

With CNC roll stands and servo control, dimensional tolerances as tight as ±0.15mm (across 4m lengths) are standard. Custom tight tolerance options available for precision installation needs.

Q4: Which industries require customized punching on angle profiles?

HVAC, petrochemical, construction, and utility sectors regularly demand pre-punched holes/slots for connectors, anchors, or conduit passage.

Q5: Is “quick die change” possible on all angle roll forming machine models?

Latest models support hydraulic quick-change systems (10–25 mins roll set swap), minimizing downtime on multi-profile or flexible production lines.

Q6: How is instrument calibration and operational validation handled?

Profile inspection via CMM, laser micrometer, and test samples are performed onsite. Remote diagnosis and parameter upload are available per request.

Q7: What is the typical installation and commissioning period?

For modular factory models, full install + test run usually completes within 3–4 weeks after equipment arrival. Operator training and ISO process validation are included in the service package.

11. Delivery Time, Warranty, and After-sales Service

- Standard Delivery: 50–65 days from deposit/payment, including functional test and export packaging.

- Warranty Period: 18–24 months mainframe warranty (extendable). Lifetime free technical support and software updates.

- Onsite/Remote Support: Global engineer dispatch for installation, troubleshooting, and training (English, Spanish, Russian available).

- Spare Parts: In-stock critical parts ready for express shipment internationally.

- Documentation: Full manual, mechanical & electrical drawing set, 3D model delivery, video tutorials.

12. Industry References & Further Reading

For further reading on angle forming machine trends, standards, and academic analysis please refer to:

- Sheet Metal Forming and Applications, International Journal of Advanced Manufacturing Technology: https://link.springer.com/article/10.1007/s00170-020-06187-8

- Best Practices for Automated Roll Forming Production, The Fabricator Forum: https://www.thefabricator.com/thefabricator/article/rollforming/best-practices-for-automated-roll-forming-production

- ISO/TC 167: Steel and aluminum structures – Roll Forming Technical Committees: https://www.iso.org/committee/53074.html

Reference sources adapted from peer-reviewed journals and leading trade forums as of 2024.

Share