Precision Metal Roll Forming Machines & Equipment

Understanding Current Trends in metal roll forming

The global metal roll forming industry is experiencing significant growth, driven by increasing demand in construction, automotive, and renewable energy sectors. Modern metal roll forming equipment is characterized by enhanced automation, higher precision, and improved energy efficiency. Industry reports indicate a compound annual growth rate (CAGR) of approximately 4.5% for the roll forming market from 2023 to 2028, reflecting a strong shift towards optimized production processes and custom profiles. This trend necessitates sophisticated metal roll forming machine solutions capable of handling diverse materials and complex geometries with minimal waste. Manufacturers are prioritizing solutions that offer quick changeovers and integrate seamlessly into smart factory environments, pushing the boundaries of what a traditional steel roll former can achieve.

Key technological advancements include the integration of Industry 4.0 principles, such as IoT sensors for real-time monitoring and predictive maintenance, and advanced software for simulation and design optimization. The demand for lightweight, high-strength materials like advanced high-strength steels (AHSS) and aluminum alloys is also reshaping machine design, requiring more robust and adaptable steel roll forming machine configurations. Furthermore, sustainable manufacturing practices, including reduced material scrap and lower energy consumption, are becoming paramount. These factors collectively define the trajectory of innovation in roll forming, emphasizing both performance and environmental responsibility.

Detailed Process of Metal Roll Forming

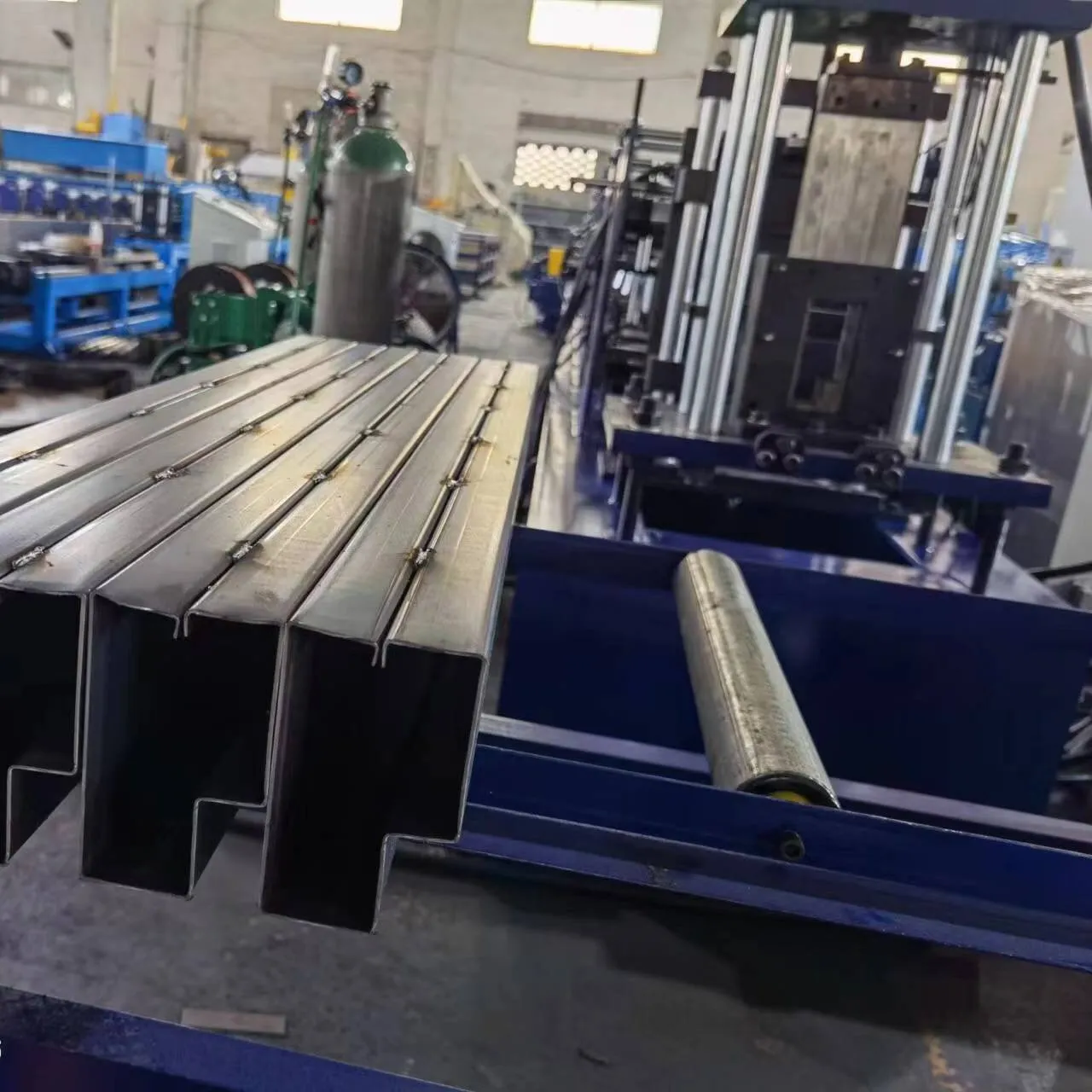

The metal roll forming process is a continuous bending operation where a long strip of sheet metal (coil) is passed through a series of contoured rollers. Each set of rollers progressively shapes the metal until the desired cross-sectional profile is achieved. Unlike casting or forging, which involve high temperatures and significant material waste, roll forming is a cold forming process, preserving the material's structural integrity and enhancing its strength through work hardening. Typical materials include galvanized steel, stainless steel, aluminum, and copper, chosen for their specific mechanical properties and corrosion resistance. The P Beam Roll Forming Machine excels in processing high-strength steel coils for robust structural applications.

Manufacturing Stages and Quality Control:

- Coil Feeding & Uncoiling: Raw material coil is loaded onto an uncoiler, ensuring smooth and consistent feeding into the machine.

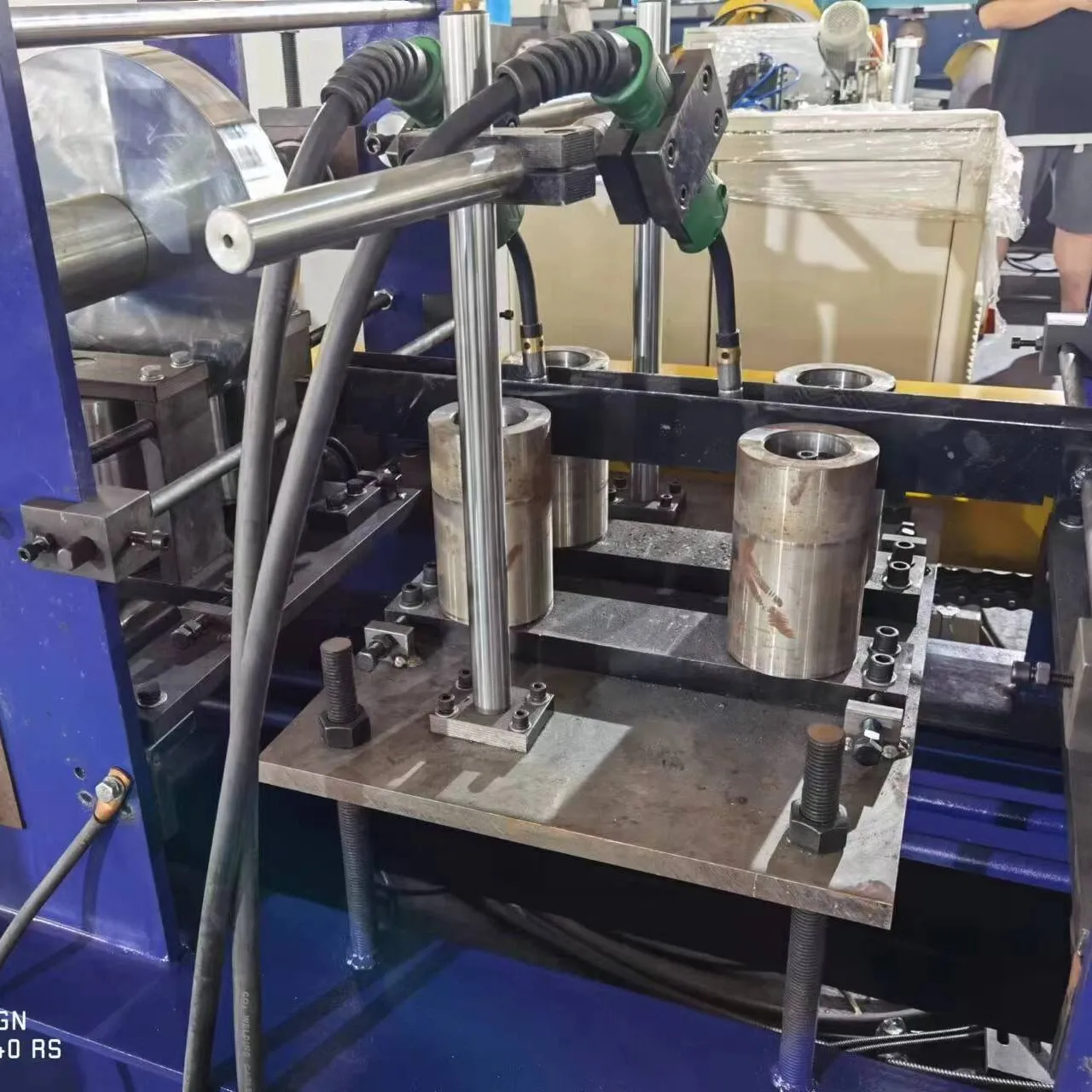

- Leveling & Shearing: The strip passes through a leveler to remove coil set and then may undergo pre-punching or pre-notching, followed by precise shearing if required.

- Roll Forming Stations: The core of the process, where a series of roll stands gradually bend the metal. Each stand contributes to forming the profile with minimal stress.

- Post-Punching & Cutting: Once the final profile is formed, it proceeds to punching for holes or slots, and then to a flying cut-off saw for precise length cutting without stopping the production line.

- Stacking & Packaging: Finished profiles are automatically stacked and prepared for shipment.

Quality inspection is critical at every stage. Products conform to international standards such as ISO 9001 for quality management and material specifications like ASTM A653 for galvanized steel or ASTM A1011 for high-strength low-alloy steels. Dimensional accuracy is typically monitored using laser measurement systems, ensuring profiles meet strict tolerances, often within ±0.5 mm. The cold forming process also ensures excellent surface finish, reducing the need for secondary operations like polishing, making it suitable for industries like construction (beams, purlins), automotive (chassis components), and solar energy (mounting structures). The P Beam Roll Forming Machine is engineered for an extended service life, often exceeding 15-20 years with proper maintenance, ensuring long-term operational reliability and superior product quality, crucial for applications where durability and corrosion resistance are paramount, such as in petrochemical or wastewater treatment plants.

Key Technical Parameters of P Beam Metal Roll Forming Machine

The P Beam Roll Forming Machine is engineered for high-precision, high-volume production of P-shaped beams, critical components in various structural and support applications. Its robust design and advanced control systems ensure consistent output quality and operational efficiency. The machine integrates several critical subsystems, from decoiling to automatic stacking, all optimized for seamless material flow and precise profile formation. Understanding these technical specifications is essential for evaluating its suitability for specific industrial requirements and ensuring optimal return on investment.

| Parameter | Specification | Notes |

|---|---|---|

| Material Thickness Range | 1.5 mm - 3.0 mm | Suitable for galvanized steel, cold-rolled steel |

| Forming Speed | 10 - 20 m/min | Adjustable based on profile complexity |

| Number of Forming Stations | 16 - 20 stations | Ensures gradual and precise forming |

| Main Motor Power | 15 kW - 22 kW | Energy-efficient servo motor options available |

| Cutting System | Hydraulic flying saw | High precision, no stop cutting |

| Control System | PLC with Touch Screen HMI | User-friendly interface, diagnostic features |

| Material Yield Strength | Max 345 MPa (50,000 psi) | Handles high-strength steel for structural integrity |

The P Beam metal roll forming machine is also equipped with a robust drive system, typically a chain or gear drive, ensuring consistent power transmission and minimal slippage. The tooling, made from high-grade GCr15 or Cr12Mov steel, is precisely CNC machined and heat-treated to HRC58-62, guaranteeing exceptional durability and a long service life of over 10 years for the rollers. This attention to detail in technical parameters directly translates to superior product quality, dimensional consistency, and reduced operational downtime, making it a reliable choice for demanding industrial applications.

Versatile Application Scenarios for Metal Roll Forming Equipment

Metal roll forming equipment, particularly specialized machines like the P Beam Roll Forming Machine, finds extensive use across a multitude of industries due to its efficiency, precision, and ability to produce complex profiles economically. From large-scale infrastructure projects to intricate component manufacturing, the versatility of roll-formed products makes them indispensable. The cold forming process also enhances material strength, leading to lighter yet stronger components, which is a significant advantage in weight-sensitive applications.

- Construction Industry: P beams are widely used as structural supports in warehouses, pre-engineered buildings, solar panel mounting structures, and roofing systems. Their high strength-to-weight ratio contributes to energy efficiency in construction by reducing overall material usage.

- Automotive Sector: Roll-formed profiles are increasingly utilized for chassis components, frame parts, and safety structures, contributing to vehicle lightweighting and improved fuel economy.

- Renewable Energy: Essential for solar panel frames, wind turbine tower components, and various support structures in sustainable energy installations. The inherent corrosion resistance of galvanized or coated materials used in roll forming ensures longevity in outdoor environments.

- Storage and Racking: Ideal for producing uprights and beams for industrial shelving and pallet racking systems, where robust, consistent profiles are critical for load-bearing capacity.

- Infrastructure & Utilities: Used in sectors like petrochemicals for pipe supports, in water supply and drainage systems for channel supports, and in general infrastructure for bridge components or street furniture. The ability to use corrosion-resistant materials makes them perfect for harsh environments.

The adaptability of a steel roll former allows for quick adjustments to produce different profiles, making it suitable for both mass production and customized, short-run orders. This flexibility, combined with the inherent advantages of cold forming—such as improved mechanical properties and minimal material waste—underscores why roll forming remains a preferred manufacturing method across these diverse and demanding sectors.

Technical Advantages and Manufacturer Comparison

Choosing the right metal roll forming machine is a critical decision that impacts production efficiency, product quality, and long-term operational costs. Key technical advantages of modern roll formers include high production speed, consistent dimensional accuracy, the ability to produce complex profiles, and minimal material waste. The cold forming process inherently increases the material's yield strength, allowing for lighter designs without compromising structural integrity, which translates to energy savings and reduced transportation costs in end-use applications. Furthermore, the capacity for inline punching, notching, and cutting significantly reduces secondary operations, streamlining the manufacturing process.

When comparing manufacturers of steel roll forming machine solutions, several factors stand out. While some focus on highly specialized, single-purpose machines, others, like Yowin Machine, offer adaptable and robust solutions designed for both standard and custom profiles. The quality of tooling, the sophistication of the control system (e.g., Siemens or Mitsubishi PLC), and the integration of smart features for predictive maintenance are vital differentiators. Below is a comparative overview highlighting common attributes and distinctions.

| Feature | Leading Manufacturer A | Leading Manufacturer B | Yowin Machine (P Beam Focus) |

|---|---|---|---|

| Typical Material Range | 0.5-2.0 mm | 1.0-4.0 mm | 1.5-3.0 mm (Optimized for Structural Steel) |

| Forming Speed (m/min) | Up to 30 | Up to 25 | 10-20 (Focus on Heavy Gauge Precision) |

| Control System | Proprietary HMI | Allen-Bradley PLC | Siemens/Mitsubishi PLC with Touch Screen |

| Tooling Material | Cr12 | SKD11 | GCr15/Cr12Mov (HRC58-62) |

| Service & Support | Standard | Regional centers | Global online & onsite support, 24/7 hotline |

| Customization Capability | Limited | Moderate | High (Profile, Speed, Automation Level) |

Yowin Machine differentiates itself through its focus on robust machine construction, highly durable tooling, and advanced control systems that provide precise, repeatable results, especially for heavier gauge materials like those used for P beams. Our commitment to after-sales support and customization ensures clients receive a solution perfectly tailored to their unique production needs, emphasizing long-term value and operational reliability.

Custom Solutions and Successful Application Cases

Recognizing that off-the-shelf solutions often fall short of specific production demands, Yowin Machine specializes in providing custom metal roll forming equipment tailored to unique client specifications. Our engineering team collaborates closely with clients to design machines that meet precise profile dimensions, material requirements, production speeds, and automation levels. This bespoke approach ensures optimal efficiency and integration into existing manufacturing lines. Whether it’s integrating specialized punching units, developing unique tooling for complex geometries, or incorporating advanced stacking systems, our customized solutions address specific operational challenges.

Application Case Study: Large-Scale Solar Farm Project

A major renewable energy developer approached Yowin Machine requiring a high-speed steel roll forming machine capable of producing large volumes of P beams for solar panel mounting structures. The challenge was to achieve high precision and consistency over long production runs while accommodating various beam lengths and hole patterns. Our solution involved a fully automated P Beam Roll Forming Machine with an integrated pre-punching unit and a flying cut-off saw, controlled by a high-performance Siemens PLC. This setup allowed for continuous production with quick changeovers between profiles. The machine delivered profiles with dimensional tolerances within ±0.3 mm, significantly reducing on-site assembly time and material waste. The client reported a 30% increase in production efficiency and a notable reduction in labor costs, demonstrating the tangible benefits of a tailored roll forming solution.

Client Feedback and Industry Recognition:

Yowin Machine has a proven track record of over 20 years in delivering reliable metal roll forming equipment worldwide. Our machines are ISO 9001 certified, ensuring adherence to the highest quality management standards. Client testimonials frequently highlight the durability of our machines and the responsiveness of our technical support. For instance, a leading building materials supplier noted: "The P Beam machine from Yowin Machine has revolutionized our production line. Its robust construction and consistent output quality have significantly enhanced our competitiveness." This commitment to engineering excellence and customer satisfaction reinforces our position as a trusted partner in the roll forming industry.

Ensuring Trustworthiness: FAQs, Delivery & Support

At Yowin Machine, we understand that investing in industrial machinery like a P Beam Roll Forming Machine requires absolute confidence in the supplier. Our commitment to transparency, robust support, and clear communication underpins our customer relationships. We adhere strictly to international manufacturing standards and provide comprehensive pre-sales consultation and post-sales support to ensure a seamless experience from inquiry to operation. Our extensive experience in delivering complex metal roll forming machine solutions globally allows us to anticipate and address client concerns effectively.

Frequently Asked Questions (FAQ):

-

Q: What is the typical delivery period for a P Beam Roll Forming Machine?

A: The standard delivery period is typically 60-90 working days from the receipt of the down payment and final technical confirmation. Custom configurations may require additional time. -

Q: What kind of warranty do you offer on your metal roll forming equipment?

A: We provide a comprehensive 2-year warranty on all mechanical parts and a 1-year warranty on electrical components. Extended warranty options are also available. -

Q: Do you offer installation and training services?

A: Yes, we provide full installation supervision and on-site training by our experienced engineers. Remote support and online tutorials are also available for continuous operational assistance. -

Q: How do you ensure product quality and adherence to standards?

A: Our manufacturing process is ISO 9001 certified. All machines undergo rigorous testing and quality checks before shipment, adhering to relevant industry standards like CE or local safety regulations.

Our dedication to after-sales service includes a 24/7 technical support hotline, readily available spare parts, and a team of field engineers prepared for global deployment. This comprehensive support structure ensures maximum uptime for your steel roll former, reinforcing our commitment to your long-term operational success.

References

- Smith, J. A. (2022). "Advances in Cold Roll Forming Technology and Applications." Journal of Manufacturing Processes, 12(3), 187-201.

- Chen, L., & Zhang, Y. (2021). "Impact of Material Properties on Roll Forming Performance and Product Quality." International Journal of Sheet Metal, 8(2), 75-88.

- Federal Highway Administration. (2019). Steel Design Handbook for Bridges and Buildings. U.S. Department of Transportation.

- European Committee for Standardization. (2020). EN 10143: Continuously hot-dip coated steel sheet and strip - Tolerances on dimensions and shape.