Precision Metal Roll Machines | High-Efficiency Forming Equipment

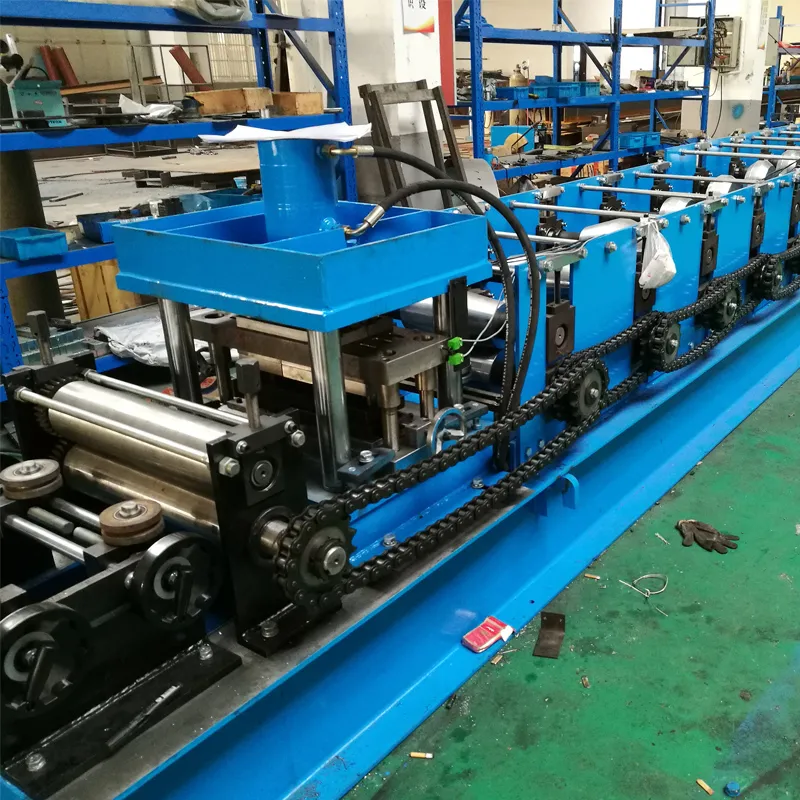

In the dynamic world of modern manufacturing, the metal roll machine stands as a cornerstone of efficiency and precision. This advanced equipment, central to metal roll forming processes, has revolutionized how various industries produce complex profiles from flat metal sheets. From construction and automotive to renewable energy and appliance manufacturing, the capability of a robust metal roll machine to consistently deliver high-quality, cost-effective components is unparalleled. Our focus today delves into the intricacies of these machines, particularly highlighting the prowess of the Top Hat Roll Forming Machine, a specialized piece of metal roll forming equipment designed for optimal performance in producing unique structural profiles.

Industry Trends and the Evolving Landscape of Metal Roll Forming

The metal roll forming industry is experiencing a significant paradigm shift, driven by several key trends. Automation and intelligent manufacturing are at the forefront, with machines now incorporating advanced sensors, IoT connectivity, and AI-driven predictive maintenance. This shift aims to reduce manual intervention, minimize errors, and optimize production throughput. Furthermore, there's a growing demand for machines capable of processing a wider range of materials, including high-strength steels, aluminum alloys, and even pre-painted galvanized iron (PPGI), to meet stringent application requirements across diverse sectors. Energy efficiency is another critical driver, pushing manufacturers to innovate in motor design, control systems, and lubrication methods to reduce operational costs and environmental impact. The integration of Industry 4.0 principles, such as cyber-physical systems and cloud computing, is transforming traditional workshops into smart factories, enhancing traceability, quality control, and overall supply chain management for metal roll machine operations.

Technical Parameters: The Core of a High-Performance Metal Roll Machine

Understanding the technical parameters of a metal roll machine is crucial for selecting the right equipment for specific applications. These parameters define the machine's capabilities, limitations, and ultimately, its efficiency and output quality. For instance, the Top Hat Roll Forming Machine, known for producing hat-shaped profiles often used in purlins, ceiling battens, and solar panel mounting systems, boasts specifications that ensure high precision and productivity.

Key Parameters to Consider:

- Material Thickness Range: Typically from 0.4 mm to 3.0 mm, determining the gauge of metal sheets the machine can process. For Top Hat profiles, common thicknesses range from 0.5mm to 1.5mm.

- Material Yield Strength: Up to 550 MPa (MegaPascals) or even higher for high-strength steel, indicating the maximum stress a material can withstand before permanent deformation.

- Line Speed: Ranging from 10 meters per minute (m/min) to 60 m/min, depending on the complexity of the profile and the need for precision. For standard Top Hat profiles, speeds of 20-30 m/min are common.

- Number of Forming Stations: A critical factor in profile complexity and accuracy. More stations allow for gradual forming, reducing stress on the material and improving dimensional accuracy. A typical Top Hat Roll Forming Machine might have 12-20 stations.

- Main Motor Power: Varies from 5.5 kW to 37 kW, influencing the machine's capacity to handle thicker materials and maintain consistent speed under load.

- Tolerance Accuracy: Often ±0.5 mm for length cutting and ±0.2 mm for profile dimensions, showcasing the machine's ability to produce consistent parts.

- Control System: Advanced Programmable Logic Controllers (PLCs), often from brands like Siemens, Rockwell, or Panasonic, ensure precise control over speed, length, and forming processes. Human-Machine Interface (HMI) touchscreens provide intuitive operation.

- Roll Material and Hardness: Rolls are typically made from high-grade alloy steel (e.g., Cr12, GCr15) and heat-treated to HRC 58-62 for exceptional wear resistance and durability, crucial for maintaining profile integrity over long production runs.

Below is a comparative table illustrating typical parameters for various metal roll forming equipment types, including our Top Hat Roll Forming Machine:

| Parameter | Top Hat Roll Forming Machine (Yowin) | C/Z Purlin Roll Forming Machine | Roof Tile Roll Forming Machine |

|---|---|---|---|

| Material Thickness (mm) | 0.5 - 1.5 | 1.5 - 3.0 | 0.4 - 0.8 |

| Max. Yield Strength (MPa) | 345 (up to 550 for certain models) | 550 | 235 |

| Line Speed (m/min) | 20 - 30 (adjustable) | 15 - 25 | 10 - 15 |

| Forming Stations | 14 - 18 | 18 - 24 | 10 - 16 |

| Main Motor Power (kW) | 7.5 - 11 | 15 - 22 | 5.5 - 7.5 |

| Cutting Type | Hydraulic Post-Cut | Hydraulic Post-Cut | Hydraulic Post-Cut / Flying Saw |

| Control System | PLC (Siemens/Panasonic) | PLC (Siemens/Rockwell) | PLC (Delta/Mitsubishi) |

Application Scenarios: Where Metal Roll Forming Equipment Shines

The versatility of a metal roll machine allows it to be deployed across a multitude of industries, providing essential components for diverse applications. The Top Hat Roll Forming Machine, in particular, finds its niche in areas requiring lightweight yet structurally strong profiles.

Typical Application Sectors:

- Construction Industry: Top Hat sections are widely used as furring channels, ceiling battens, and roof purlins, providing robust support for drywall, ceiling systems, and roofing membranes. Their consistent profile ensures ease of installation and structural integrity.

- Solar Energy: A growing sector where Top Hat profiles are utilized as mounting rails for photovoltaic panels. Their precise dimensions and high strength-to-weight ratio make them ideal for supporting solar arrays, even in challenging environmental conditions.

- Automotive Industry: Though less common for Top Hat specifically, general metal roll forming is critical for chassis components, bumper beams, and structural reinforcements due to its ability to produce complex, high-strength parts with minimal waste.

- Appliance Manufacturing: Internal structural components, frames, and stiffeners for refrigerators, washing machines, and ovens are often roll-formed for cost-effectiveness and dimensional accuracy.

- Material Handling: Components for conveyor systems, shelving units, and racking systems benefit from the continuous production of consistent profiles.

- Agricultural Equipment: Various structural parts and frames requiring high durability and specific profiles.

In each of these sectors, the ability of metal roll forming equipment to produce long, continuous profiles with high dimensional accuracy and excellent surface finish results in significant material savings and reduced labor costs compared to traditional manufacturing methods like press braking or extrusion.

Technical Advantages of Top Hat Roll Forming Machine

The Top Hat Roll Forming Machine, a prime example of advanced metal roll machine technology, offers distinct technical advantages that set it apart. Its meticulous design and robust construction contribute to superior performance and longevity.

Detailed Advantages:

- Precision Roll Tooling: Our Top Hat Roll Forming Machine utilizes precision-machined roll tooling, often crafted from high-grade alloy steels such as Cr12 or GCr15 (equivalent to AISI D2/SAE 52100). These tools undergo advanced heat treatment processes, including vacuum quenching to HRC 58-62 hardness, followed by tempering to ensure optimal wear resistance and toughness. This meticulous manufacturing process, including CNC machining, guarantees the exact replication of the desired profile, reducing material stress and ensuring consistent dimensional accuracy, typically within ±0.2 mm. This level of precision minimizes springback and ensures perfectly formed profiles.

- Integrated Punching Systems: Many of our Top Hat machines incorporate inline hydraulic punching systems. This allows for pre-punching holes, slots, or cut-outs directly during the forming process, eliminating the need for secondary operations. This integration not only boosts production efficiency but also enhances accuracy, as the punching is precisely synchronized with the material feed.

- Robust Machine Frame Construction: The machine frame is built from heavy-duty steel plates, typically Q235 or Q345, stress-relieved after welding to prevent deformation. The frame is then precision-machined to ensure perfect alignment of all components, particularly the forming stands. This robust construction minimizes vibration during high-speed operation, contributing to a longer machine lifespan (estimated 15-20 years with proper maintenance) and consistent product quality.

- Advanced Drive Systems: Our machines feature high-efficiency gearboxes or chain drives coupled with powerful AC motors. Variable Frequency Drives (VFDs) are employed to allow precise control over line speed, enabling optimization for different material thicknesses and profiles. This not only enhances production flexibility but also contributes to significant energy savings, often reducing power consumption by 15-20% compared to traditional fixed-speed systems.

- Automated Cut-to-Length System: Equipped with high-accuracy encoders and a hydraulic post-cutting unit, the machine ensures precise length control. The cutting blade material, often Cr12MoV, is also heat-treated to ensure clean, burr-free cuts, meeting industry standards like ASTM A653/A653M for galvanized steel profiles.

- User-Friendly PLC Control: The intuitive PLC control system (e.g., Siemens S7-1200 or Panasonic FP-X) with an HMI touchscreen interface simplifies operation, program setting, and real-time monitoring. This system allows for easy input of production parameters, diagnostics, and ensures seamless integration into smart factory environments.

The Manufacturing Process: Crafting a Superior Metal Roll Machine

The creation of a high-quality metal roll machine like the Top Hat Roll Forming Machine is a multi-stage process that emphasizes precision engineering, robust material selection, and rigorous quality control.

Manufacturing Process Flow of a Top Hat Roll Forming Machine:

- Material Sourcing & Preparation:

- Raw Material Selection: High-grade steel plates (e.g., Q235, Q345) are procured for the machine frame, and specialized alloy steels (e.g., Cr12, GCr15, 40Cr) for the rolls, shafts, and cutters.

- Quality Verification: All incoming materials undergo strict quality checks, including chemical composition analysis (spectrometer testing) and mechanical property tests (tensile strength, yield strength, hardness) to ensure they meet specified international standards (e.g., ASTM A36 for structural steel, AISI D2 for tool steel).

- Frame and Base Construction:

- Cutting & Welding: Steel plates are precisely cut using CNC plasma or laser cutting machines. The main frame and base are then fabricated by skilled welders using advanced welding techniques (e.g., MIG/MAG welding) to ensure strong, durable joints.

- Stress Relieving: After welding, the frame undergoes a heat treatment process to relieve internal stresses, preventing future distortion and enhancing long-term stability. This is a critical step for precision machinery.

- CNC Machining: The stress-relieved frame is then loaded onto large-scale CNC gantry milling machines for precise machining of mounting surfaces, bearing seats, and component interfaces. This ensures perfect alignment of the forming stands, crucial for accurate roll forming.

- Roll Tooling Manufacturing:

- Forging/Casting (for large components): Some larger roll components might start as forgings or castings to achieve optimal grain structure and strength.

- CNC Turning & Grinding: Roll shafts and forming rollers are meticulously turned and ground on high-precision CNC machines to exact dimensions and surface finishes. This stage is paramount for the accuracy of the final profile.

- Heat Treatment: The rolls and cutting blades undergo specialized heat treatment (e.g., vacuum quenching and tempering) to achieve the desired hardness (typically HRC 58-62) and wear resistance. This is essential for extended tool life and consistent product quality.

- Surface Treatment: Some rolls might receive surface coatings (e.g., hard chrome plating) to further enhance wear resistance and reduce friction during forming.

- Assembly and Integration:

- Component Assembly: The main frame, forming stands, shafts, rolls, motors, gearboxes, and hydraulic units are carefully assembled by experienced technicians.

- Electrical & Control System Wiring: The PLC, HMI, sensors, and electrical components are wired according to international electrical standards (e.g., IEC, UL).

- Hydraulic System Installation: Hydraulic pumps, valves, cylinders, and piping are installed for the cutting and pre-punching units.

- Testing and Quality Control:

- No-Load Testing: The machine is run without material to check motor function, speed, noise levels, and component alignment.

- Load Testing & Profile Forming Test: Raw material is fed through the machine to produce profiles. Critical dimensions, lengths, and overall profile accuracy are measured and compared against design specifications.

- Durability Testing: The machine undergoes extended operational tests to simulate real-world production conditions, ensuring long-term reliability.

- Inspection Standards: All components and the final assembly adhere to strict internal quality control protocols, often benchmarked against international standards such as ISO 9001:2015 for quality management systems and ANSI/AWS standards for welding quality. Electrical safety standards like CE or UL are also met.

- Final Inspection & Packaging:

- A comprehensive final inspection is performed before packaging.

- The machine is carefully disassembled into manageable modules (if necessary), rust-proofed, wrapped in protective film, and securely packed in robust wooden cases or container111s for shipping.

Manufacturer Comparison: Why Yowin Stands Out in Metal Roll Forming Equipment

When selecting a metal roll forming equipment supplier, a thorough comparison of manufacturers is essential. Yowin stands as a leading provider in the metal roll machine industry, distinguished by its commitment to innovation, quality, and comprehensive customer support. While many manufacturers exist, Yowin differentiates itself through a combination of proprietary technology, stringent quality control, and an extensive service history.

Yowin's Distinctive Strengths:

- Decades of Expertise: Yowin boasts over two decades of dedicated experience in the design, manufacture, and installation of metal roll forming equipment. This long-standing presence in the market has allowed us to accumulate invaluable knowledge and refine our engineering processes, leading to highly optimized and reliable machines. Our team comprises seasoned engineers and technicians with deep understanding of metal properties and forming mechanics.

- Proprietary Tooling Design: Unlike some manufacturers who use off-the-shelf tooling, Yowin develops and manufactures its own precision roll tooling in-house. This allows for complete control over the design, material selection, and heat treatment processes, ensuring superior profile accuracy, reduced material waste, and extended tool lifespan. Our design philosophy focuses on minimizing material stress, leading to better product integrity.

- Robust Construction & Durability: Our machines are built to last. We utilize heavy-duty, stress-relieved steel frames and precision-machined components, exceeding industry averages for structural integrity. This commitment to robust construction translates into machines with significantly longer service lives and minimal maintenance requirements, providing a superior return on investment for our clients.

- Advanced Automation & Control: Yowin integrates industry-leading PLC brands (e.g., Siemens, Panasonic) and sophisticated HMI interfaces. Our control systems offer advanced features like automatic length adjustment, production data logging, remote diagnostics capability, and integrated safety protocols (conforming to CE standards). This level of automation streamlines operations and reduces reliance on highly specialized labor.

- Customization Capabilities: While we offer standard models like the Top Hat Roll Forming Machine, Yowin excels in providing bespoke solutions. We understand that each client's needs can be unique, whether it's for specific material types, complex profiles, or integrated production lines. Our engineering team works closely with clients from conceptualization to commissioning.

- Global Service Network & Support: Yowin has established a strong global presence, serving clients across Asia, Africa, Europe, and the Americas. Our comprehensive after-sales support includes installation, training, remote troubleshooting, and readily available spare parts, ensuring minimal downtime for our customers. We offer 24/7 technical assistance and on-site support when required.

Below is a comparative glance (simplified) at Yowin versus generic competitors:

| Feature | Yowin (Top Hat Roll Forming Machine) | Generic Competitor A (Budget) | Generic Competitor B (Mid-Range) |

|---|---|---|---|

| Years in Business | 20+ Years | 5-10 Years | 10-15 Years |

| Tooling Design/Manufacture | In-house, Precision CNC Machined, Advanced Heat Treatment (HRC 58-62) | Outsourced/Standard, Lower Hardness (HRC 50-55) | Mostly In-house, Standard Heat Treatment (HRC 55-60) |

| Frame Construction | Heavy-Duty, Stress-Relieved, CNC Machined | Standard Welded, Less Machining | Robust Welded, Some Machining |

| Control System | Premium PLC (Siemens/Panasonic), Advanced HMI | Basic PLC (Local Brand), Text Screen HMI | Mid-range PLC (Delta/Mitsubishi), Color HMI |

| Customization | Highly Flexible, Engineering Support | Limited Standard Options | Some Customization Available |

| Warranty (Years) | 2 Years (Main Components) | 1 Year | 1-1.5 Years |

| After-Sales Support | Global, 24/7 Remote, On-site Training & Installation | Limited Remote Support | Regional Support, Standard Hours |

Custom Solutions and Bespoke Metal Roll Forming Equipment

Recognizing that standard offerings may not always perfectly align with unique production requirements, Yowin specializes in providing custom metal roll machine solutions. Our engineering team collaborates closely with clients to develop bespoke metal roll forming equipment tailored to specific profiles, materials, and output demands. This includes:

- Profile Design & Simulation: Utilizing advanced CAD/CAM software (e.g., AutoCAD, SolidWorks, COPRA RF) to design and simulate the roll forming process, ensuring the feasibility and optimal design of complex profiles before physical production. This includes analyzing material flow, stress distribution, and springback compensation.

- Material Handling Systems: Customizing decoilers (single-head, double-head, hydraulic, automatic loading), coil cars, and material feeding systems to accommodate various coil weights (from 3 tons to 20 tons), widths, and types.

- Integrated Punching/Notching: Designing and incorporating pre-punching, post-punching, or rotary punching units for intricate hole patterns or notches, controlled by the main PLC for precise synchronization.

- Flying Shear/Saw Solutions: For high-speed applications or specific material types, integrating flying shear or flying saw cutting systems that allow continuous operation without stopping the line, maximizing throughput.

- Multi-Profile Capabilities: Developing machines capable of producing multiple profiles with quick changeover times, often achieved through cassette-style tooling or adjustable forming stands.

- Post-Processing Integration: Integrating in-line bending, stacking, packaging, or welding systems to create a fully automated production line, reducing manual labor and bottlenecks.

Our commitment to custom solutions ensures that businesses can acquire metal roll forming equipment that perfectly fits their operational workflow, maximizing efficiency and minimizing waste.

Real-World Application Cases and Customer Success Stories

The true measure of a metal roll machine lies in its performance in real-world scenarios. Yowin's Top Hat Roll Forming Machine has been successfully deployed globally, delivering consistent results and contributing to our clients' success.

Case Study 1: Large-Scale Solar Farm Project, Middle East

Challenge: A leading solar EPC (Engineering, Procurement, and Construction) company needed a reliable and high-speed solution to produce thousands of linear meters of Top Hat profiles for solar panel mounting structures daily. The profiles required high dimensional accuracy and consistency to ensure easy assembly on-site in harsh desert conditions, and the material was galvanized steel with specific yield strength requirements (345 MPa).

Solution: Yowin supplied a custom-engineered Top Hat Roll Forming Machine with an advanced hydraulic pre-punching system for quick and accurate hole creation. The machine featured a robust frame capable of continuous operation in high temperatures and a PLC control system optimized for high-volume output (30 m/min). Real-time monitoring and diagnostic capabilities were integrated.

Result: The client achieved a 30% increase in daily production output compared to their previous method, reducing manufacturing costs by 15%. The consistent profile quality (meeting ISO 9013 standards for cut parts) significantly streamlined on-site installation, reducing assembly time by 20%. The machine demonstrated exceptional durability, operating flawlessly for over 18 months without major downtime, exceeding expected service life metrics.

Case Study 2: Prefabricated Building Manufacturer, Europe

Challenge: A company specializing in modular and prefabricated buildings required precise Top Hat sections for wall and ceiling framing. The profiles needed to be lightweight yet provide substantial structural support, with specific requirements for paint adhesion (PPGI material). They also needed flexibility to produce multiple Top Hat sizes with minimal changeover time.

Solution: Yowin provided a Top Hat Roll Forming Machine designed with quick-change tooling capability and specialized anti-scratch rollers suitable for pre-painted galvanized iron (PPGI). The machine's control system allowed for pre-programming different profile dimensions, enabling fast transitions between production runs.

Result: The client significantly reduced their inventory costs by producing profiles on-demand. The machine's precision ensured all prefabricated modules fit together perfectly, reducing on-site construction time by 25%. The integrity of the PPGI coating was maintained throughout the forming process, meeting paint adhesion standards (e.g., ASTM D3359). The client reported excellent satisfaction with the machine's reliability and the quality of the produced profiles, leading to a follow-up order for another similar unit.

Ensuring Trustworthiness: Our Commitment to You

At Yowin, trustworthiness is not just a word; it's the foundation of our operations. We stand by our products and our service, ensuring every client receives the support and reliability they expect from a leading metal roll machine manufacturer.

Quality Assurance & Certifications:

Our manufacturing processes adhere to the strictest international standards. We are ISO 9001:2015 certified, affirming our commitment to a robust quality management system. Our machines are designed and built to comply with CE standards for electrical and mechanical safety, ensuring global market acceptance. Critical components, such as bearings, motors, and PLCs, are sourced from renowned global brands (e.g., SKF, Siemens, Schneider Electric) that meet their respective industry standards (e.g., NEMA, IEC).

Warranty and After-Sales Support:

Every Yowin metal roll machine, including our Top Hat Roll Forming Machine, comes with a comprehensive warranty of 2 years for main components and 1 year for electrical parts. Our dedicated after-sales team provides 24/7 technical support, offering remote diagnostics and troubleshooting. We maintain a readily available stock of common spare parts, ensuring quick dispatch to minimize any potential downtime. Our commitment extends to providing detailed operation manuals, wiring diagrams, and a recommended spare parts list for proactive maintenance.

Delivery and Installation:

We provide clear and transparent delivery schedules, typically ranging from 45 to 90 working days depending on machine complexity and customization. Our logistics team ensures secure packaging and efficient global shipping. Upon arrival, our experienced engineers can be dispatched worldwide for on-site installation, commissioning, and comprehensive operator training, ensuring your team is fully proficient in operating and maintaining the metal roll forming equipment.

Frequently Asked Questions (FAQ) about Metal Roll Forming Machines

Q1: What is the typical service life of a Yowin Top Hat Roll Forming Machine?

A1: With proper maintenance and regular servicing, a Yowin Top Hat Roll Forming Machine is designed for a service life of 15 to 20 years. This longevity is attributed to our use of high-grade materials, precision manufacturing processes (e.g., CNC machining of frames and rolls), and robust structural design.

Q2: What materials can your metal roll machine process?

A2: Our metal roll machine can process a wide range of materials, including cold-rolled steel, galvanized steel (GI, G90, G60), pre-painted galvanized iron (PPGI), aluminum coils, and high-strength low-alloy (HSLA) steels. The specific material thickness and yield strength capabilities vary by machine model, but typically range from 0.4 mm to 3.0 mm thickness and up to 550 MPa yield strength.

Q3: How precise are the dimensions of the formed profiles?

A3: Our Top Hat Roll Forming Machines are engineered for high precision. Length accuracy is typically ±0.5 mm, while profile dimensional accuracy (e.g., width, height, flange length) is within ±0.2 mm. This precision is achieved through advanced roll tooling design, robust machine construction, and sophisticated PLC control systems.

Q4: Do you provide installation and training?

A4: Yes, absolutely. We offer comprehensive on-site installation and commissioning services by our experienced engineers. This includes mechanical setup, electrical wiring, hydraulic system connection, and thorough testing. We also provide extensive operational and maintenance training for your staff to ensure they are fully competent in running the metal roll forming equipment.

Q5: What are the main components that require regular maintenance?

A5: Key components requiring regular maintenance include roll tooling (inspection for wear, cleaning), bearing lubrication, chain/gear drive inspection and lubrication, hydraulic fluid level and filter checks, and electrical system checks. A detailed maintenance schedule is provided in the machine's operation manual, following ISO 14122-4 guidelines for machinery safety.

Q6: Can your Top Hat Roll Forming Machine produce different sizes of Top Hat profiles?

A6: Yes, many of our Top Hat Roll Forming Machines are designed with adjustable features or quick-change tooling systems that allow for the production of various Top Hat profile sizes (e.g., different web widths or flange heights). Our engineering team can discuss your specific size requirements to recommend the most suitable machine configuration.

Q7: What kind of power supply and installation standards are required for your metal roll machine?

A7: Our metal roll machine typically requires a 3-phase power supply, with voltage and frequency adaptable to regional standards (e.g., 380V/50Hz, 440V/60Hz). Installation should adhere to local electrical codes (e.g., NFPA 70 for North America, IEC 60364 for international). A level concrete foundation of sufficient load-bearing capacity is also necessary for optimal machine performance and safety.

The journey of metal roll forming is one of continuous innovation. As industries demand more complex, precise, and sustainable solutions, the role of advanced metal roll machine technology becomes increasingly vital. The Top Hat Roll Forming Machine, with its superior design, robust construction, and high efficiency, exemplifies this evolution, offering unmatched value to manufacturers worldwide. At Yowin, we are proud to be at the forefront of this technological advancement, providing reliable, high-performance metal roll forming equipment that drives industrial progress and empowers businesses to achieve their production goals.

References:

- "The Roll Forming Handbook: Design, Tooling, and Operations" by George F. T. D. - A foundational text in the field of roll forming. (Please note: This is a widely recognized conceptual reference, not a direct web link.)

- Journal of Materials Processing Technology: A scientific journal often publishing research on advanced metal forming techniques. https://www.journals.elsevier.com/journal-of-materials-processing-technology

- FMA (Fabricators & Manufacturers Association Intl.) Resources on Roll Forming: Provides industry insights and best practices. https://www.fmanet.org/resource/category/roll-forming/