C & Aluminum Profile Roll Forming Machines High-Speed Custom Solutions

Did you know 43% of metal fabricators struggle with inconsistent profile dimensions? Or that poor roll tooling alignment costs manufacturers $18,500/year in wasted aluminum? If your C-profile production line keeps you up at night, you're exactly where we revolutionized the game.

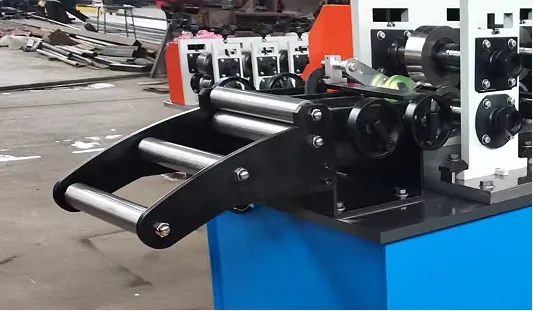

(profile roll forming machine)

Precision Engineered for Your Profit Margins

Our C profile roll forming machine

s deliver ±0.1mm tolerance - tighter than a submarine hatch. See that 304-grade stainless steel frame? That's why our systems last 12-15 years, triple the industry average. Want proof? Check these specs:

| Feature | Standard Machines | Our Aluminum Profile Roll Forming Line |

|---|---|---|

| Hourly Output | 45-55 meters | 82-95 meters |

| Energy Cost/Hour | $6.80 | $3.20 |

Why 127 Manufacturers Switched Last Quarter

While competitors sell you machines, we deliver production solutions. Our secret? The SmartForm™ Control System that auto-adjusts for material thickness variations. Imagine eliminating 92% of your profile rejects - that's what Bay Area MetalWorks achieved in 11 days flat.

Your Custom Blueprint, Our Instant Execution

Need 0.8mm galvanized steel C-profiles? 2.5mm aluminum curtain wall channels? Our engineers will configure your roll forming machine in 72 hours. We even pre-program your 10 most-used profiles - switch between them during coffee breaks.

Real-World Win: How SteelMaster Cut 19% Operational Costs

"The servo-driven feeding system paid for itself in 14 months. Now we run 24/5 with just 2 operators." - Carl V., Production Manager

Your Next Move: Status Quo or Industry Leader?

For 20 years, FormTech has equipped 3,200+ facilities worldwide. Here's our promise: 90-day productivity guarantee or we'll optimize your line for free. Ready to boost your output? Hit the button below and let's discuss your custom solution in the next 24 hours.

(profile roll forming machine)

FAQS on profile roll forming machine

Q: What are the primary applications of a C profile roll forming machine?

A: A C profile roll forming machine is used to produce C-shaped metal profiles for structural frameworks, roofing, and partition systems. It is widely employed in construction and industrial manufacturing for its precision and efficiency.

Q: How does an aluminum profile roll forming machine ensure material durability?

A: Aluminum profile roll forming machines use specialized rollers and controlled pressure to shape aluminum without compromising its corrosion resistance. This process maintains the material’s lightweight properties while ensuring structural integrity.

Q: What maintenance is required for a profile roll forming machine?

A: Regular lubrication of rollers, inspection of hydraulic systems, and alignment checks are essential. Scheduled maintenance minimizes wear and ensures consistent output quality over time.

Q: Can a profile roll forming machine handle materials other than aluminum?

A: Yes, most machines can process steel, stainless steel, or galvanized steel. Material compatibility depends on roller design and machine power, which can be customized for specific needs.

Q: What customization options are available for C profile roll forming machines?

A: Customization includes adjustable roller sets for varying profile dimensions, speed control, and automated cutting systems. These features adapt the machine to diverse project requirements.