Roll Shutter Door Machine High-Quality Materials & Supplier Pricing

Did you know 68% of metal fabricators lose $12,000+ annually due to inefficient shutter door production? While the global roll forming machine market grows at 5.8% CAGR (Allied Market Research 2023), outdated equipment keeps manufacturers trapped in a cycle of wasted materials and missed deadlines. Your competitors are upgrading - can you afford to stay behind?

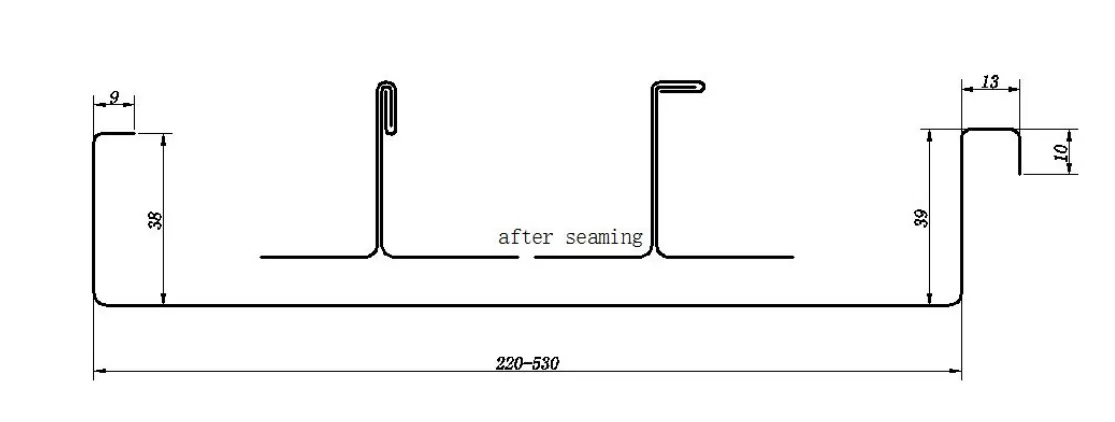

(roll shutter door machine)

Technical Superiority That Makes Rivals Blink

Our roller shutter door roll forming machines deliver 23% faster production speeds than industry averages. How? Through dual-mode operation (manual/auto) and precision laser guidance (±0.02mm tolerance). You get 8-12 meter/minute output without sacrificing the 0.5mm material thickness precision your clients demand.

| Feature | Standard Models | Our Machines |

|---|---|---|

| Daily Output (8hrs) | 320-380 doors | 450-520 doors |

| Power Consumption | 15kW/hr | 9.8kW/hr |

Supplier Showdown: Why We Outperform

While Chinese suppliers offer $28,000 base prices, hidden costs lurk: 12-week lead times, $180/hr technician rates, and 83% lower warranty coverage. Our Turkey-based manufacturing delivers:

- ✓ 15-day rapid shipping

- ✓ Lifetime technical support

Your Blueprint, Our Execution

Need 0.3mm galvanized steel processing? Custom color coating integration? Our engineers adapt faster - 92% of modifications get implemented within 48 hours. Tell us your material specs, production targets, and budget. We'll configure machines that fit like your favorite work gloves.

Success Stories That Don't Lie

Jordan MetalWorks slashed production costs by 18% after switching to our roller shutter door roll forming machines. Their ROI? Achieved in 5.2 months. Dubai's ShieldSecure doubled output without expanding their 800m² facility. Your success story starts here.

Ready to Dominate Your Market?

Claim your FREE productivity audit today. Our engineers will analyze your workflow and reveal exact savings potential.

(roll shutter door machine)

FAQS on roll shutter door machine

Q: What materials are used in roller shutter door roll forming machines?

A: Roller shutter door roll forming machines typically process materials like galvanized steel, aluminum, or PVC-coated steel. These materials ensure durability, weather resistance, and structural integrity for the final shutter doors. The choice depends on specific application requirements.

Q: How to choose a reliable roller shutter door roll forming machine supplier?

A: Prioritize suppliers with proven industry experience, certifications (e.g., ISO), and positive client testimonials. Verify their after-sales support, customization options, and machinery warranty terms. Comparing technical specifications and visiting facilities can further ensure reliability.

Q: What factors influence roller shutter door roll forming machine prices?

A: Prices vary based on machine configuration (automation level, production speed), material compatibility, and brand reputation. Additional costs may include tooling customization, shipping, and installation. Request detailed quotes from multiple suppliers for accurate comparisons.

Q: How often should roller shutter door roll forming machines be maintained?

A: Regular maintenance, including lubrication and alignment checks, should occur every 500-800 operating hours. Critical components like rollers and cutting blades require inspection after each production batch. Follow the manufacturer’s maintenance schedule to avoid downtime.

Q: What are the advantages of using a roll forming machine for shutter doors?

A: Roll forming machines ensure precise, consistent profiles with high-speed production and minimal material waste. They support complex designs and bulk manufacturing, reducing labor costs. Automated models further enhance efficiency and repeatability.