Top Cable Tray Manufacturing Machines & Roll Forming Solutions

Navigating the Landscape of Cable Tray Production

The global demand for efficient and robust cable management solutions continues to surge, driven by rapid urbanization, industrial expansion, and the escalating need for reliable power and data infrastructure. This burgeoning market has propelled advancements in manufacturing technologies, making the cable tray manufacturing machine a cornerstone of modern industrial production. These sophisticated machines are pivotal in producing a variety of cable trays—from ladder type and perforated to solid bottom and wire mesh—essential for supporting and protecting electrical cables across diverse sectors. Understanding the nuances of these machines, including their operational capabilities, material handling, and adherence to international standards, is critical for businesses aiming for high-volume, precision manufacturing. The industry trends point towards increased automation, energy efficiency, and the integration of smart technologies, enabling manufacturers to meet stringent project specifications and reduce operational costs.

The evolution of the cable tray manufacturing machine reflects a broader shift towards precision engineering and lean manufacturing principles. Modern machines are designed not only for speed but also for accuracy and flexibility, capable of processing various material thicknesses and types, including pre-galvanized steel (GI), stainless steel (SS), and aluminum. This adaptability ensures that manufacturers can cater to the specific demands of different environments, whether it's the corrosive atmosphere of a chemical plant or the high-load requirements of a data center. Furthermore, the integration of advanced control systems, such as PLC (Programmable Logic Controller) and HMI (Human-Machine Interface), provides unparalleled control over the production process, minimizing human error and maximizing output efficiency. Investing in a state-of-the-art cable tray machine translates directly into enhanced productivity and a competitive edge in the rapidly evolving infrastructure market.

Automatic Cable Tray Roll Forming: A Detailed Process Overview

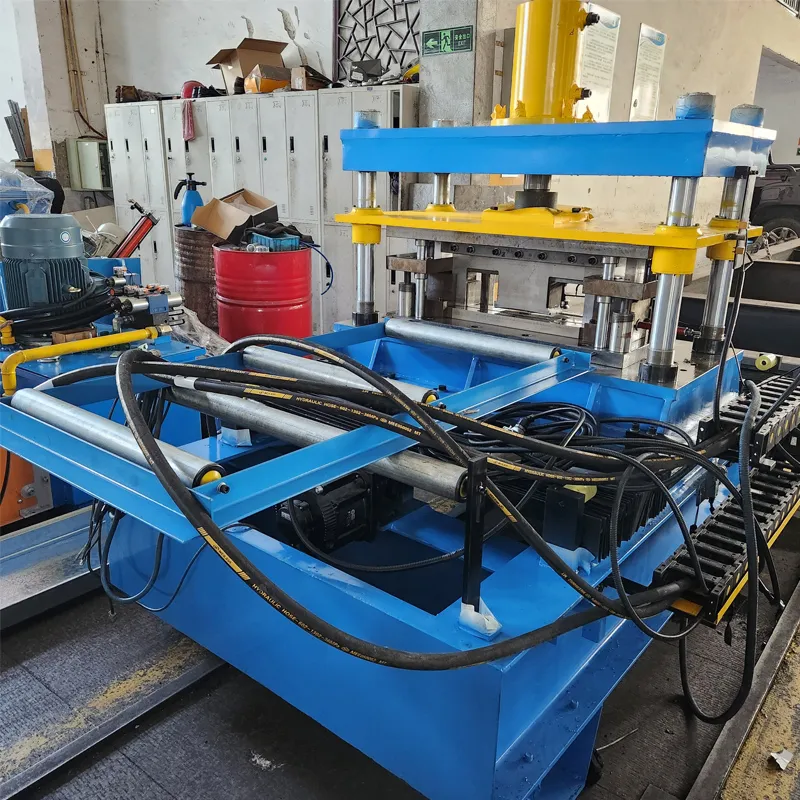

The manufacturing of cable trays using an Automatic Cable Tray Roll Forming Machine is a highly automated and precise multi-stage process, ensuring consistent quality and high production rates. The journey begins with the decoiling of the raw material coil, typically high-strength galvanized steel, stainless steel, or aluminum, which are chosen based on the required corrosion resistance and load-bearing capacity. This material is then fed through a leveling and guiding system to ensure perfect alignment and flatness before entering the core roll forming section. Here, a series of precisely engineered roll dies progressively shape the flat sheet into the desired cable tray profile, minimizing material stress and ensuring dimensional accuracy. This intricate roll forming process, unlike traditional methods like stamping or bending, offers superior precision and material integrity, crucial for meeting industry standards such as NEMA VE 1 and IEC 61537 for cable management systems. The structural integrity achieved through roll forming is paramount for the long-term reliability of the installed cable trays in demanding industrial environments.

Following the roll forming stages, the shaped profile advances to the punching station, where a high-speed hydraulic or mechanical punching unit creates the necessary holes and slots for ventilation, mounting, and connecting accessories. The precision of this punching process, often controlled by servo motors, is critical for seamless assembly on-site. Subsequently, the formed and punched cable tray profile is cut to the specified length by a hydraulic or servo cutting mechanism, ensuring clean edges and exact dimensions. Throughout this entire sequence, advanced sensors and a sophisticated PLC control system continuously monitor parameters like speed, length, and profile integrity. This closed-loop feedback system allows for real-time adjustments, guaranteeing that the finished product adheres to stringent quality control metrics, including ISO 9001 standards for manufacturing excellence. The final step involves automated stacking and bundling, preparing the finished cable trays for dispatch. This streamlined process minimizes waste and labor costs while maximizing throughput.

Key Technical Specifications and Parameters

Choosing the right cable tray making machine requires a thorough understanding of its technical specifications, which directly impact production capabilities and product quality. A high-performance Automatic Cable Tray Roll Forming Machine is characterized by its ability to handle a wide range of material thicknesses, typically from 1.0mm to 3.0mm, and produce various tray widths and heights. The operational speed, often measured in meters per minute (m/min), is a crucial factor for evaluating output efficiency, with advanced systems reaching speeds of 10-20 m/min or higher. Power requirements, the number of forming stations, and the type of cutting and punching systems (e.g., hydraulic, servo-driven) are also vital considerations. The machine's control system, usually a Siemens or Panasonic PLC with a user-friendly HMI, ensures precise control over every step of the manufacturing process, from coil feeding to finished product stacking.

Typical Automatic Cable Tray Roll Forming Machine Parameters

| Parameter | Typical Range / Value |

|---|---|

| Material Thickness | 1.0 mm - 3.0 mm (Galvanized Steel, Stainless Steel, Aluminum) |

| Production Speed | 10 - 20 m/min (adjustable) |

| Forming Stations | 14 - 24 stations (depending on profile complexity) |

| Punching System | Hydraulic or Servo-driven, multi-station |

| Cutting System | Hydraulic or Servo-driven post-cutting |

| Control System | PLC (Siemens/Panasonic) with HMI Touch Screen |

| Motor Power | 15 kW - 45 kW (main motor) |

| Machine Dimensions | Approx. 12m - 20m (length, depending on configuration) |

| Accuracy | Length tolerance ±0.5mm, Profile tolerance ±0.5mm |

These parameters are crucial for optimizing production capacity and ensuring that the finished cable trays meet specific project requirements, from heavy-duty industrial installations to sensitive data centers. A well-configured cable tray manufacturing machine price often correlates with these advanced features and the overall build quality, reflecting its long-term reliability and performance. Precision components, robust construction, and intelligent control systems contribute significantly to the machine's efficiency and the quality of the end product.

Advanced Features and Technological Advantages

Modern cable tray roll forming machine systems incorporate several technological advancements that set them apart, delivering significant operational advantages. One primary advantage is the integration of advanced automation, which minimizes manual intervention and dramatically reduces labor costs while enhancing safety. Features such as automatic coil loading, integrated leveling, and pre-punching units streamline the entire production flow. Furthermore, the use of high-precision servo motors for feeding and punching ensures exceptional accuracy in hole placement and cut lengths, critical for standardized component assembly. This precision is vital for compliance with international installation guidelines, such as those from NEMA for cable tray systems, ensuring compatibility and ease of installation in complex projects.

Another key advantage lies in the energy efficiency of contemporary machines. Optimized hydraulic systems, energy-saving motors, and intelligent control algorithms significantly reduce power consumption, contributing to lower operating expenses and a smaller carbon footprint. The modular design of many cable tray machine manufacturer offerings allows for easy customization and scalability, enabling manufacturers to adapt their production lines to changing market demands without extensive retooling. For instance, quick-change tooling systems allow for rapid transitions between different cable tray profiles, enhancing versatility. Moreover, remote diagnostics capabilities and IoT integration are emerging features, allowing for predictive maintenance, real-time performance monitoring, and rapid troubleshooting, which collectively boost uptime and extend the machine's operational lifespan, leading to a superior return on investment.

Applications Across Diverse Industries

The versatility of cable trays produced by an advanced cable tray manufacturing machine makes them indispensable across a multitude of industries. In the petrochemical sector, for instance, stainless steel cable trays offer superior corrosion resistance, crucial for protecting vital electrical conduits in harsh chemical environments. Similarly, in metallurgy, heavy-duty perforated cable trays provide robust support for large power cables, with their open design facilitating heat dissipation. For water treatment and wastewater facilities, specialized coated or galvanized trays ensure longevity against moisture and corrosive agents. The ability to produce trays with specific finishes, such as hot-dip galvanized for outdoor use or powder-coated for aesthetic and additional protection, significantly extends their applicability. These machines enable manufacturers to meet stringent industry-specific standards for safety and performance, ensuring reliable cable management in critical infrastructure projects.

Beyond traditional heavy industries, cable trays are foundational in commercial and institutional buildings, data centers, and renewable energy installations. In commercial infrastructure, such as shopping malls and office complexes, solid bottom or perforated trays are used for organized cable routing, often concealed within ceilings or above raised floors. Data centers rely heavily on ladder-type and wire mesh trays to manage vast networks of data and power cables, appreciating their open structure for easy access and ventilation, which prevents overheating. The consistent quality and precise dimensions achieved by a high-end cable tray making machine ensure seamless installation and long-term reliability in these complex, critical environments. This broad applicability underscores the strategic importance of investing in robust and adaptable manufacturing technology to serve an ever-growing array of industrial and commercial demands.

Choosing Your Cable Tray Machine Manufacturer and Customization Solutions

Selecting the right cable tray machine manufacturer is a decision that extends beyond just the initial cable tray manufacturing machine price. It involves evaluating a manufacturer's expertise, track record, and capability to provide comprehensive support and customization. A reputable manufacturer will possess deep industry knowledge, evidenced by years of service and a portfolio of successful installations globally. Their adherence to international quality management systems, such as ISO 9001:2015, is a strong indicator of their commitment to excellence in design, production, and after-sales service. It’s essential to consider factors like the use of globally recognized components (e.g., Siemens, Schneider, Rexroth), robust machine construction for durability, and the availability of spare parts. Furthermore, a manufacturer's capacity for innovation, adapting to new material sciences and automation trends, is crucial for long-term partnership.

Customization is a cornerstone of meeting diverse industry needs. Leading manufacturers offer tailored solutions for their cable tray manufacturing machine systems, including specific profile designs, varying material thickness capabilities, and integrated punching patterns to match unique project specifications. This bespoke approach allows clients to produce specialized cable trays that perfectly fit their application, whether it requires unique dimensions for a constricted space or specific hole configurations for proprietary mounting systems. For instance, some projects might require specific types of return flanges or unique side wall heights, which can be accommodated through custom roll design. The ability to integrate additional features like automatic stacking systems, online welding, or integrated deburring units further enhances the machine's efficiency and the quality of the final product, directly impacting the profitability and market competitiveness of the buyer. Engaging with a manufacturer who prioritizes R&D and offers flexible engineering solutions ensures that your investment continues to meet evolving demands.

Case Studies and Client Success

Our Automatic Cable Tray Roll Forming Machine has been instrumental in the success of numerous projects worldwide, demonstrating its robust performance and reliability. In a recent project for a large-scale data center in Europe, our machine enabled the production of over 100,000 meters of perforated cable trays within a tight 3-month deadline. The client praised the machine's consistent output quality, minimal downtime, and the precision of its punching system, which significantly accelerated the on-site installation process. The ability to produce trays conforming strictly to NEMA standards was a critical factor in the project's success and compliance. This success story underscores the direct impact of high-quality machinery on project timelines and overall operational efficiency, transforming raw materials into critical infrastructure components with unparalleled speed and accuracy.

Another notable application involved a complex infrastructure expansion project in the Middle East, requiring a variety of heavy-duty ladder-type cable trays for an oil and gas refinery. The harsh environmental conditions necessitated galvanized steel trays with specific load-bearing capacities. Our cable tray manufacturing machine, equipped with specialized tooling and reinforced structural components, consistently produced trays that met the rigorous ASTM and ISO standards for corrosion resistance and strength. The client reported a 30% reduction in material waste compared to previous methods and highlighted the machine's user-friendly HMI, which allowed for quick adjustments and minimal operator training. These real-world applications exemplify how investing in a high-performance cable tray machine manufacturer translates into tangible benefits, including cost savings, improved product quality, and enhanced project delivery capabilities across diverse and demanding industrial environments.

Frequently Asked Questions (FAQ)

-

Q: What materials can your cable tray manufacturing machine process?

A: Our Automatic Cable Tray Roll Forming Machine is designed to process a variety of materials including pre-galvanized steel (GI), hot-dip galvanized steel, stainless steel (SS304, SS316), and aluminum, catering to diverse environmental and load requirements.

-

Q: How customizable are the cable tray profiles?

A: Our machines offer extensive customization options. We can design and integrate specific roll tooling to produce various cable tray profiles, including different widths, heights, flange types, and punching patterns, according to your specific project needs.

-

Q: What is the typical delivery period for a new machine?

A: The standard delivery period for an Automatic Cable Tray Roll Forming Machine typically ranges from 60 to 90 working days, depending on the machine's configuration and customization requirements. Specific timelines are provided upon order confirmation.

-

Q: What kind of after-sales support and warranty do you offer?

A: We provide comprehensive after-sales support including installation assistance, operator training, and remote technical support. Our machines come with a standard one-year warranty on mechanical and electrical components, with options for extended service agreements. We ensure quick response times for parts and service to minimize downtime.

Warranty, Delivery, and Customer Support

Our commitment to client success extends far beyond the sale of a cable tray manufacturing machine. We understand that post-purchase support is crucial for maximizing your investment and ensuring continuous production. Our standard warranty typically covers one year for major mechanical and electrical components, underscoring our confidence in the durability and quality of our engineering. We adhere to clear and efficient delivery protocols, with typical lead times for custom-built Automatic Cable Tray Roll Forming Machines ranging from 60 to 90 working days, depending on specific configurations and the complexity of customized tooling. This timeframe accounts for meticulous design, precision manufacturing, rigorous testing, and quality assurance checks before shipment.

Our dedicated customer support team is available to provide comprehensive assistance, from initial consultation and machine setup to ongoing technical support and maintenance. We offer on-site installation and training services globally, ensuring your team is fully proficient in operating and maintaining the equipment. For urgent issues, remote diagnostic capabilities allow our engineers to troubleshoot and guide your technicians, minimizing downtime and maximizing operational efficiency. We also maintain a readily available stock of critical spare parts, ensuring prompt replacements and reducing potential disruptions to your production schedule. This holistic approach to service ensures that your cable tray making machine operates at peak performance throughout its extensive lifespan, providing long-term value and reliability.

Conclusion and Future Outlook

The demand for high-quality, efficiently produced cable trays continues to grow, making the investment in an advanced cable tray manufacturing machine an increasingly strategic decision for manufacturers worldwide. By leveraging cutting-edge roll forming technology, coupled with precise punching and cutting mechanisms, these machines offer unparalleled productivity, material efficiency, and product quality. The ability to customize profiles, integrate automation, and ensure compliance with international standards positions manufacturers to capture significant market share in critical infrastructure projects across various industries. As the industry moves towards more integrated and intelligent manufacturing, the role of sophisticated machinery will only expand, driving innovation in design, material usage, and operational sustainability. Partnering with an experienced and reliable cable tray machine manufacturer is paramount to navigate this evolving landscape and secure a competitive advantage.

Choosing the right cable tray manufacturing machine is a long-term investment that promises substantial returns through enhanced production capabilities, reduced labor costs, and superior product quality. The integration of smart manufacturing principles, predictive maintenance, and energy-efficient designs will continue to shape the next generation of these essential machines. For any enterprise looking to scale its cable tray production or enhance its product quality, selecting a machine that embodies precision, durability, and technological foresight is essential. This forward-looking approach ensures that your operations remain at the forefront of the industry, capable of meeting the dynamic demands of a globally interconnected world.

References

- National Electrical Manufacturers Association. (NEMA VE 1-2017). _Metal Cable Tray Systems_.

- International Electrotechnical Commission. (IEC 61537:2006). _Cable management systems - Cable tray and cable ladder systems_.

- International Organization for Standardization. (ISO 9001:2015). _Quality management systems — Requirements_.

- ASTM International. (Various standards for steel and aluminum materials, e.g., ASTM A653/A653M for galvanized steel).

- The Engineering Handbook. (2018). _Roll Forming Process and Applications_. CRC Press.