-

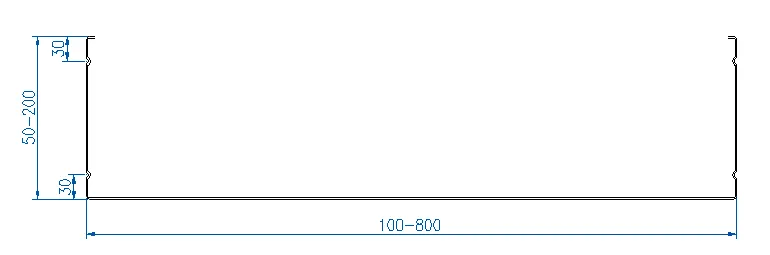

Drawings

-

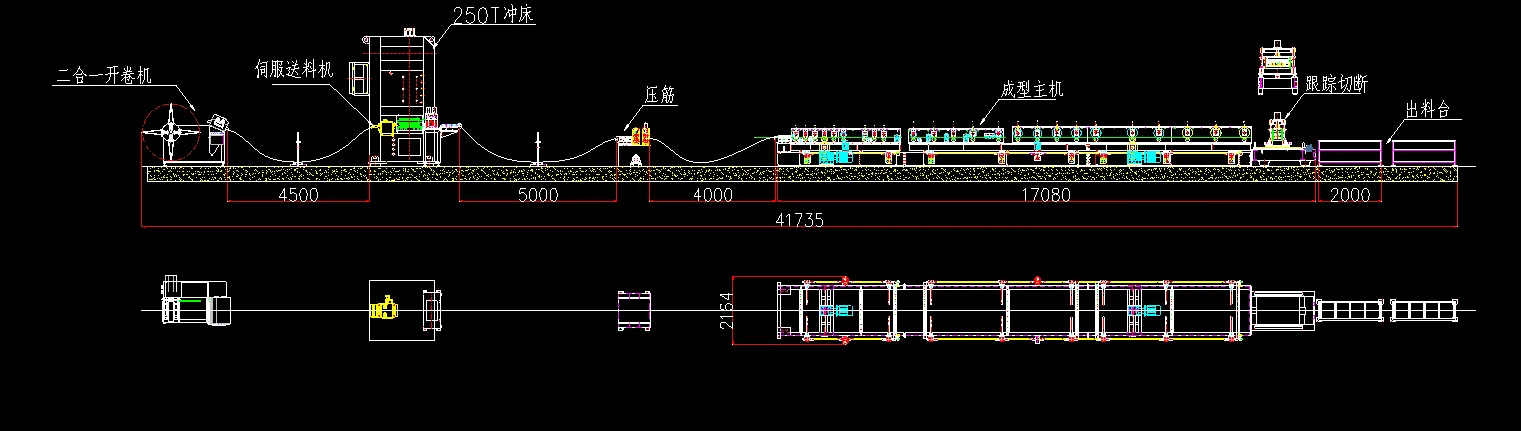

Flow chat

Component

|

Decoiler with leveling machine |

1 set |

|

NCF-900 servo feeder |

1 set |

|

250T punching machine with punch die |

1 set |

|

Servo track hydraulic cutting with Shrinkage device |

1 set |

|

Main roll forming machine |

1 set |

|

PLC control system |

1 set |

|

Receiving table (3M * 2) |

1 set |

Parameters and specification

I.Decoiler with leveling machine

Uncoiler: Active feeding, hydraulic tension

Capacity: 10T

Inner diameter of uncoiler support coil: φ 508mm

Support range: φ 470-530mm

Steel coil width: ≤ 900mm

Outer diameter of steel coil: 1300mm

Hydraulic system power of uncoiler: 1.5KW

Motor power: 7.5kw

Leveling mechanism structure: two roller pinch, seven roller leveling

Leveling roller shaft diameter: approximately φ 52.5mm

Leveling roller material: high-quality 40Cr

Leveling shaft heat treatment method: surface high-frequency quenching treatment

II.NCF-900 servo feeder

|

Name |

Type |

NCF-900mm |

|

Servo feeder system |

1.:Width |

<900mm |

|

2.Thickness: |

0.8-2.0mm |

|

|

3.Speed: |

20m/min |

|

|

4.Feeding length: |

9999.99 |

|

|

5.Feeding accuracy: |

≤1m±0.2 |

|

|

6.Release methods: |

Pneumatic type |

|

|

7.Roller frame pressing method: |

Spring type |

|

|

8.Feeding roller: |

4-axis, 2-group |

|

|

9.Retaining wheel: |

2 sets, manual adjustment |

|

|

10.Adjusting the width of the retaining material: |

70mm-900mm |

|

|

11.Feeding servo motor |

5.5KW |

|

|

12.Color: |

As customer request |

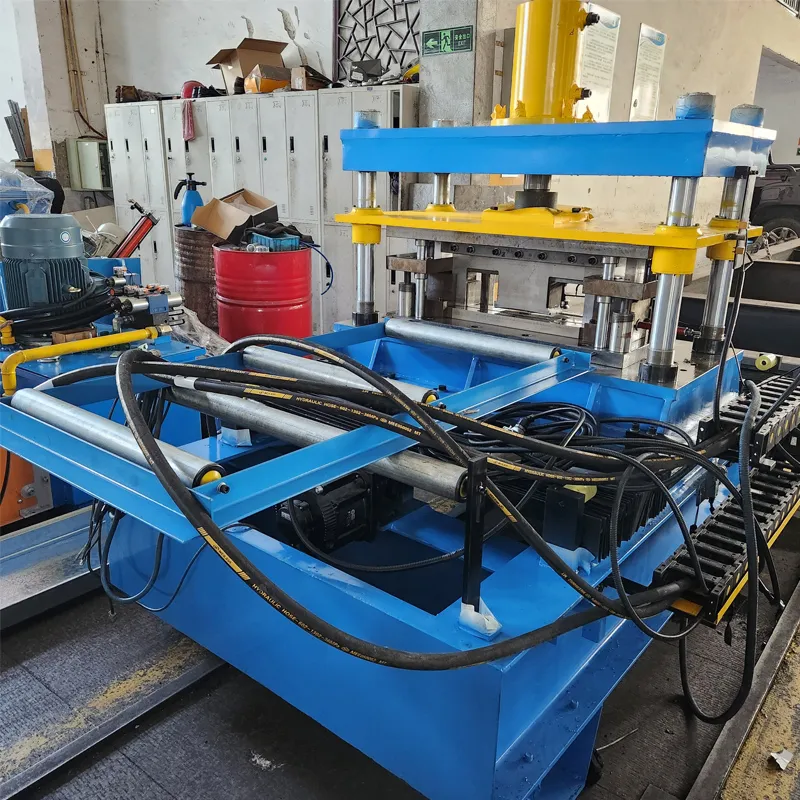

III.250T punching machine with punch die

1.Type:JH21-250

2.Nominal force:250T

3.Rated toque journey:6mm

4.Slide stroke:200mm

5.Stroke times:35

6.Maximum Die Set Height:450mm

7.Adjustment amount of mold installation height:110mm

8.Workbench size:760mm×1400mm

9.Size of the bottom surface of the slider:600×800

10.Main motor power:22kw

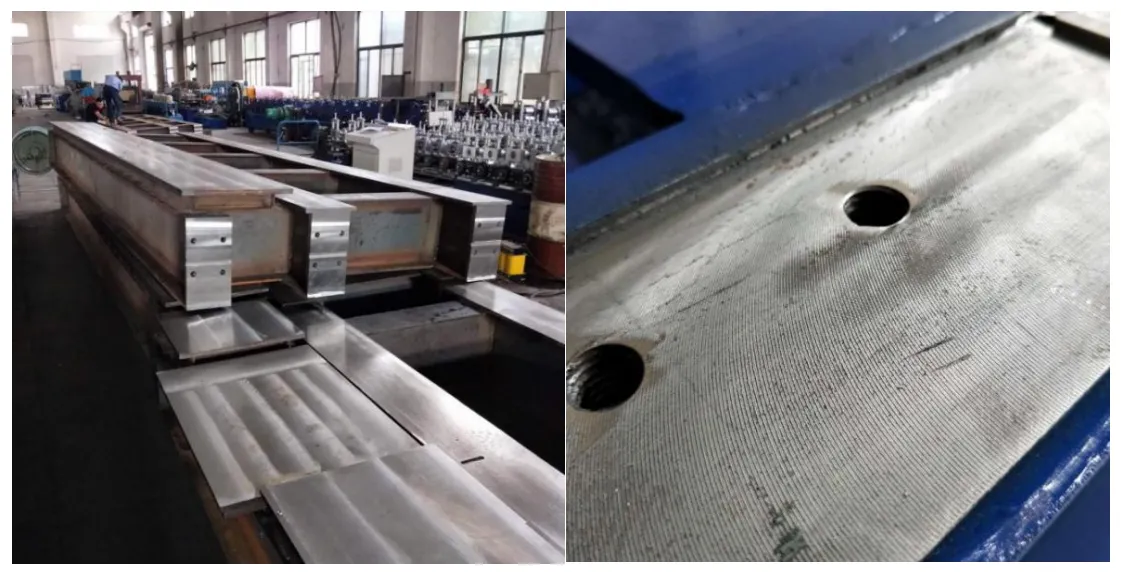

Punching die

1.Punching mold: 1 pair (this mold is a core pulling mold with a step distance of 150mm and a production speed of every

Minute punching times step distance, the height specification of the bridge side is 40/60. When producing different height specifications, the mold adopts core pulling treatment; The width specification of the bridge is 50-600, and the length measurement is ± 1mm

- 2. Material of upper and lower templates (upper and bottom plates): high-quality 45 # carbon steel, ultra precision grinding processing.

- 3. Upper and lower mold materials (punch and die): Cr12MOV

- 4. Heat treatment method for upper and lower molds: quenching HRC58-6

- 5. Material of cutting die upper and lower blades: H13

- 6. Heat treatment method for upper and lower knives: quenching treatment (HRC54-56)

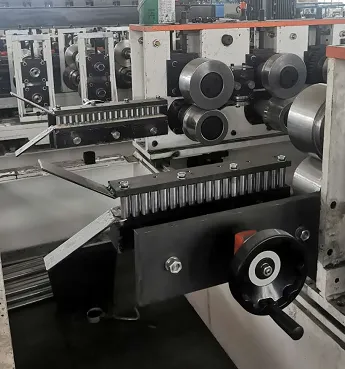

IV.Main roll forming machine

1.Profile section: subject to mutual confirmation

2.Applicable plate: carbon steel, galvanized plate ≤ 2.0mm

3.Applicable plate thickness: 0.8-2.0mm

4.Forming machine frame: High quality steel welded and aging treated

5.Molding machine structure: cast iron memorial archway type automatic traverse

6.Transmission: gearbox

7.Guide feed frame form: side handwheel type, guide roller quenching treatment. (When left and right guides are set at the feed inlet of the main machine, the raw material plates enter the main machine through left and right guides on both sides to maintain the correct position between the raw material plates and the rolling forming system. The guide position can be adjusted manually through a screw mechanism, and the left and right are independently adjustable. When changing specifications automatically, the guide mechanism moves laterally with the main machine.)

8.Shaftsmaterial: 40Cr quenched and tempered (HB220-260)

9.Shaftsdiameter: approximately Φ 60/80mm

10.Mainpower: 15KWx1 unit

11.The total rate of transverse motor is about 0.75kw2 units+1.5kw2 units

12.Linear speed of forming machine: 0-8 meters/min

13.Quantity of the stand: 26(including correction)

14.Production specifications: height 40mm-100mm (adjustable), width 100mm-600mm (adjustable)

15.Roll material: Gcr15mov quenching treatment (HRC58-62)

-

V.Servo track hydraulic cutting with Shrinkage device

-

VI.Receiving table

1.Material receiving roller table structure: angle steel welding, without power

2.Receiving roller diameter: approximately Φ 60mm

3.Transfer roller table specification: 800x1500mmx2 pieces

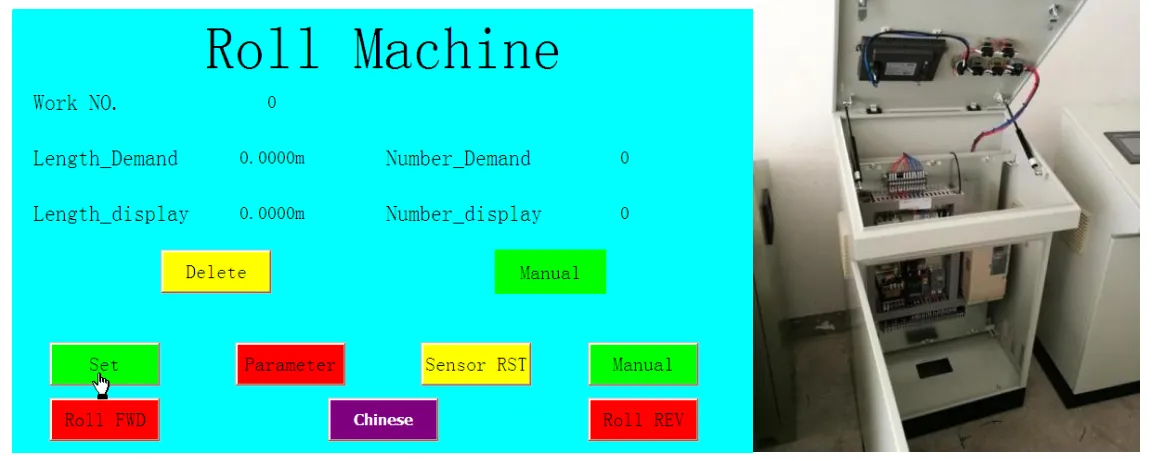

VII.Control system

Adopting PLC control technology and variable frequency speed regulation technology to achieve complete machine automation production. The system provides a friendly human-machine interface, which can set batch, workpiece length, quantity, etc. Operation method: touch frequency+button.

Encoder: Guangyang, with counting and length counting functions.

PLC: Panasonic or Delta, Japan

Frequency converter: Yaskawa or Delta

Master control unit: Schneider

Keys and contactors: Schneider

Touch screen: MCGS