-

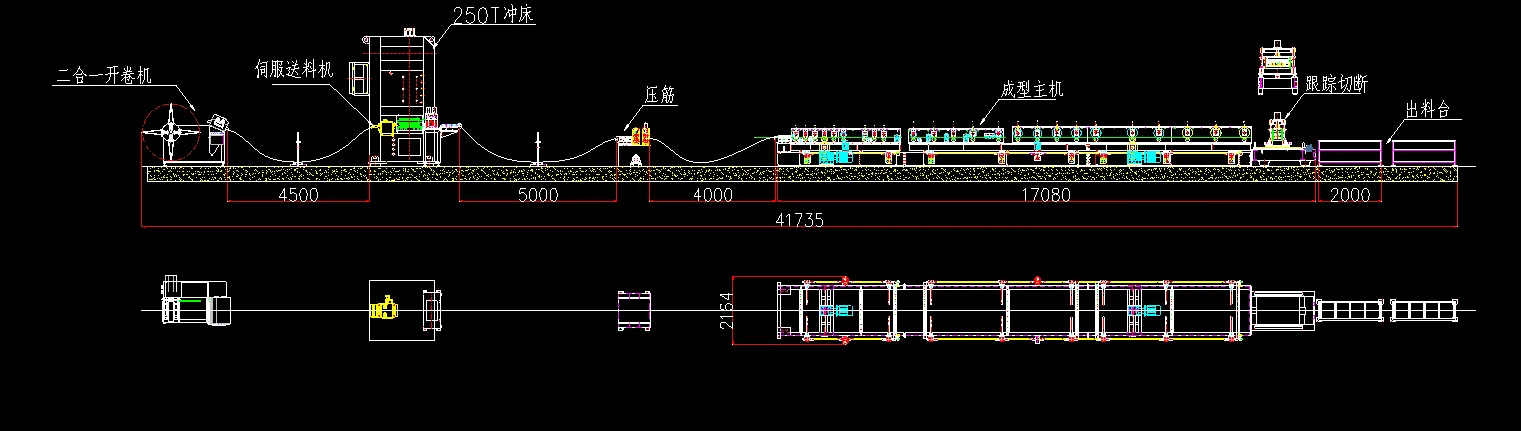

Drawings

-

Curabitur influunt

Component

|

Decoiler cum adtritio machina |

1 set |

|

NCF-CM servo satietas |

1 set |

|

250T apparatus punching cum ferrum mori |

1 set |

|

Servo track hydrau secans DECREMENTUM fabrica |

1 set |

|

Pelagus volumine formatam machinam |

1 set |

|

PLC imperium systema |

1 set |

|

Mensa acceptio (3M*2). |

1 set |

Parametri et specificationem

Et ego.Decoiler cum adtritio machina

Uncoiler: Active pascens, hydrau tensio

Facultas: 10T

Inner diameter of uncoiler support coil: φ 508mm

Support range: φ 470-530mm

Steel coil width: ≤ 900mm

Diameter exterior coil: 1300mm

Hydraulica systematis potentia uncoiler: 1.5KW

Potentia motoria: 7.5kw

Adaequatio mechanismi structura: duo cylindrus ternum, septem cylindrus adaequatio

Leveling roller shaft diameter: approximately φ 52.5mm

Adtritio cylindro materia: summus qualitas 40Cr

Hastile adtritio curatio calor modum: superficies summus frequentia curatio exstinguitur

II.NCF-CM servo satietas

|

Nomen |

Type |

NCF-900mm |

|

Servo satietas ratio |

1.: Latitudo |

<900mm |

|

2.Thickness |

0.8-2.0mm |

|

|

3.Speed: |

20m/min |

|

|

4.Feeding longitudinem |

9999.99 |

|

|

5.Feeding accuracy |

≤1m±0.2 |

|

|

6.Release modi |

Genus pneumaticum |

|

|

7.Roller frame modum premendi |

Ver genus |

|

|

8.Feeding cylindro |

4-axis, 2-group |

|

|

9.Retaining rota |

2 sets, manuale commensuratio |

|

|

10.Adjusting latitudine retinendi materia |

70mm-900mm |

|

|

11.Feeding servo motricium |

5.5KW |

|

|

12.Color: |

Ut Lorem petitionem |

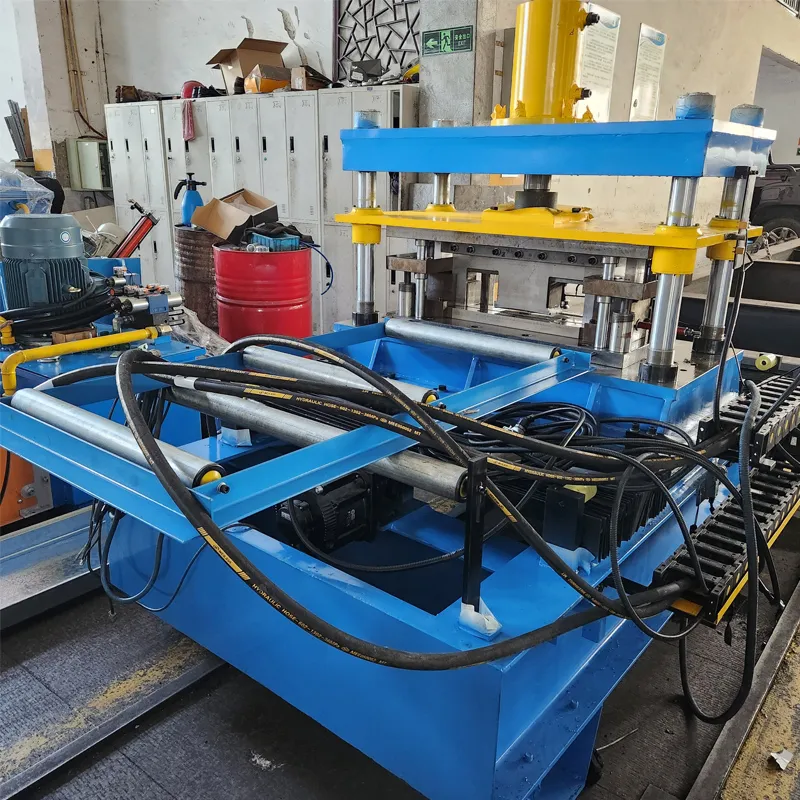

III.250T machina pulsandi per ferrum mori

1.Type:JH21-250

2.Nominal vis: 250T

3.Rated toque iter: 6mm

4.Slide ictum: 200mm

5.Stroke times: 35

6.Maximum Die Set Height:450mm

7.Adjustment amount of fingunt institutionem altitudo: 110mm

8.Workbench size:760mm×1400mm

9.Size of the bottom surface of the slider:600×800

10.Main motricium potentia: 22kw

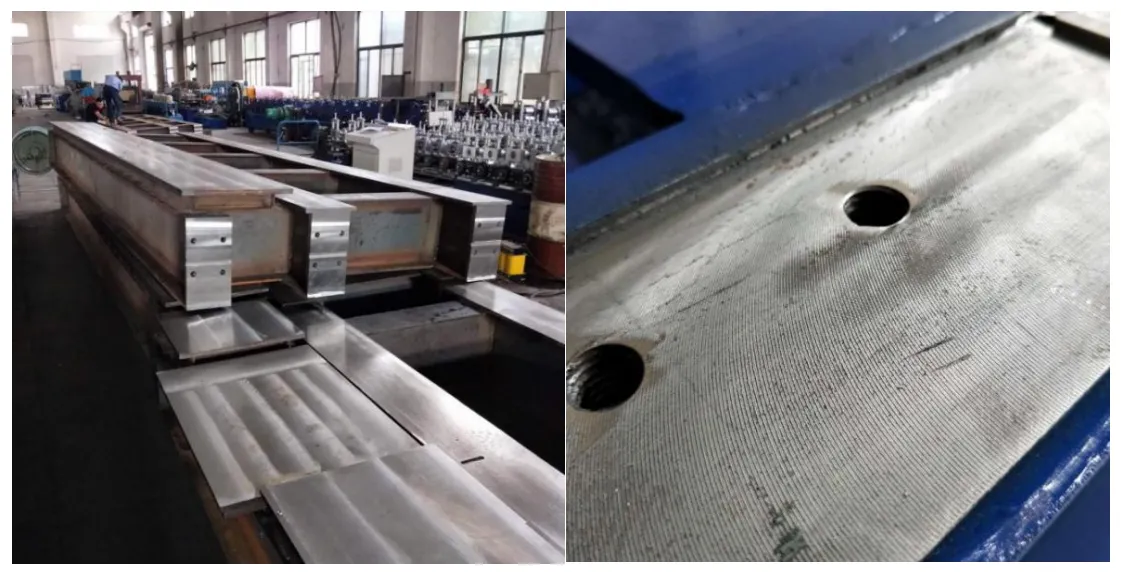

Punging mori

1.Punching fingunt: 1 par (haec forma est core forma trahens cum gradum distantiae 150mm et celeritas productio omnis

Minute punching times step distance, the height specification of the bridge side is 40/60. When producing different height specifications, the mold adopts core pulling treatment; The width specification of the bridge is 50-600, and the length measurement is ± 1mm

- 2. Materia templates superiorum et inferiorum (laminae superioris et inferioris): qualitas summus 45 # chalybe carbonis, ultra praecisionem processus stridor.

- 3. Materiae formae superioris et inferioris (ferrum et mori): Cr12MOV

- 4. Methodus curationum caloris formas superiores et inferiores: exstingui HRC58-6

- 5. Material secandi mori laminas superiores et inferiores: H13

- 6. Methodus curationis caloris cultelli superioris et inferioris: curatio exstinguiendi (HRC54-56)

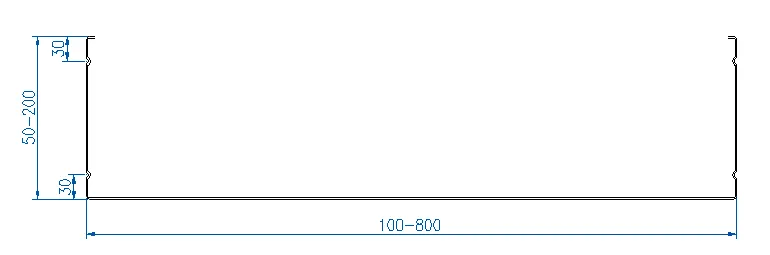

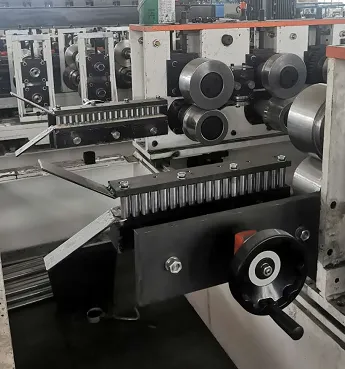

IV.Main roll formatam machinam

1.Profile section: mutuae confirmationis subiectum est

2.Applicable plate: carbon steel, galvanized plate ≤ 2.0mm

3.Applicable laminae crassitudine: 0.8-2.0mm

4.Forming machinae frame: High quality chalybe iuncta et senescente tractata

5.Molding machina compages: ferrea emittere arcui genus automatic traicere

6.Transmission: gearbox

7.Guide pascere frameam formam: latus handwheel genus, dux cylindrus exstingui curatio. (Cum sinistrae dextraeque duces ponuntur ad pascuum diverticulum machinae principalis, laminae materiales intrant machinam principalem per laevam et dextram utrinque ad rectam positionem inter laminas materiales rudis et volvens ratio formandi. Dux positio manually per cochleam mechanismum accommodari potest, et dextra laevaque independenter aptabiles sunt. Mutato specificatione automatice, dux machina mechanismus movetur lateraliter.

8.Shaftsmaterial: 40Cr extincta et temperata (HB220-260)

9.Shaftsdiameter: approximately Φ 60/80mm

10.Main potestatem: 15KWx1 unit

11. Totalis rate transversus motor est circa 0.75kw2 unitates+1.5kw2 unitates

12.Linear celeritatem formandi apparatus: 0-8 metris / min

13.Quantity of the stand: 26(including correction)

14.Production specifications: altitudo 40mm-100mm (adjustable), latitudo 100mm-600mm (adjustable)

15.Roll material: Gcr15mov curatio exstinguibilis (HRC58-62)

-

V.Servo track hydrau secans DECREMENTUM fabrica

-

WE.Accipiens mensam

1.Material accepto cylindro tabulae structurae: glutino ferro angulus, sine potentia

2.Receiving roller diameter: approximately Φ 60mm

3.Transfer cylindrus mensam specificationem: 800x1500mmx2 pieces

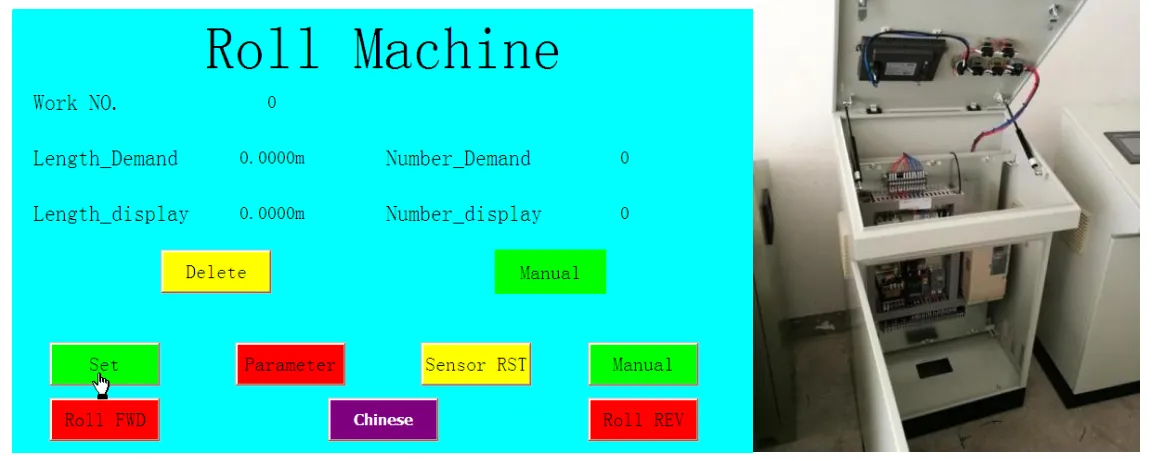

VII.Control system

Adoptatione PLC potestate technologiae et variae frequentiae velocitatem moderandi technologiam ad perficiendam machinam automationem perficiendam. Systema amicabilem machinam humanam instrumenti praebet, quae massam, workpieces longitudinem, quantitatem, etc. Operationis modum praebet: frequentiam+button tangat.

Encoder: Guangyang, munera numerandi et longitudinem numerandi.

PLC: Panasonic vel Delta, Iaponia

Frequency converter: Yaskawa vel Delta

Magister ditionis unitatis: Schneider

Claves et contactores: Schneider

Tactus screen: MCGS