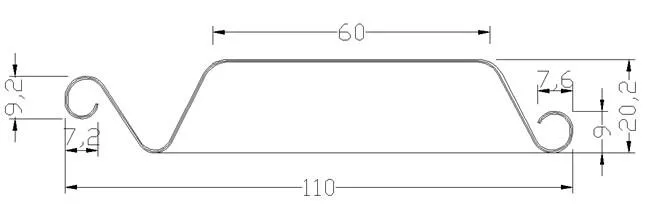

Drawings

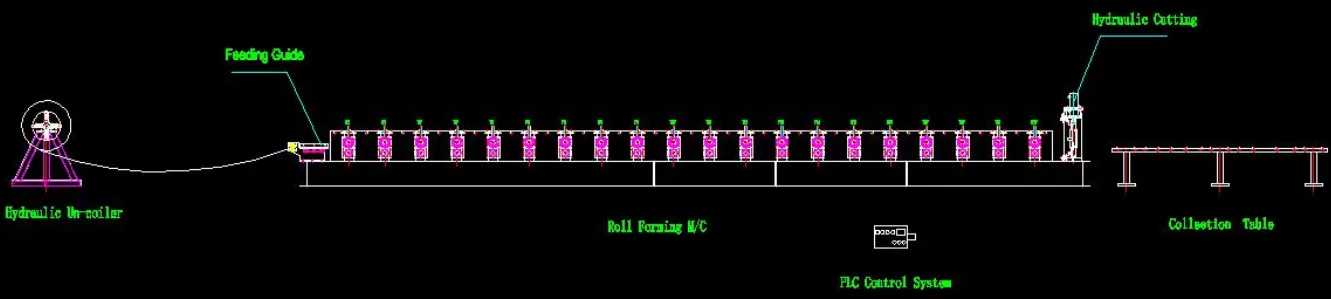

Processes and components

| De-coiler | x1 set |

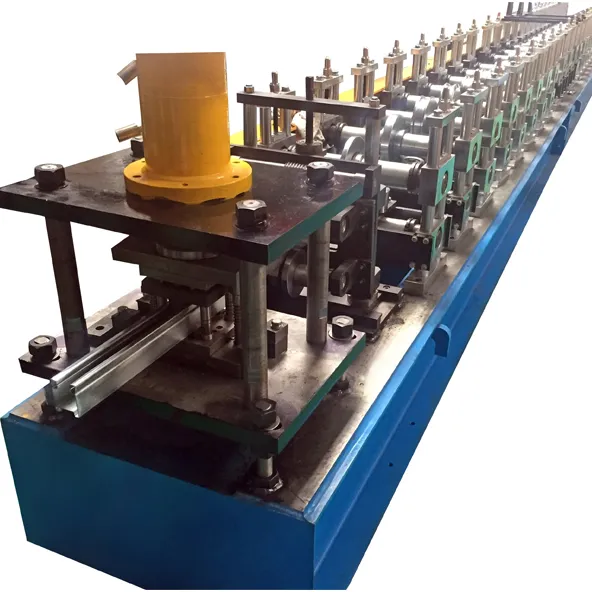

| Main roll forming machine | x1 set |

| Hydraulic cutting system | x1 set |

| Hydraulic station | x1 set |

| PLC Control system | x1 set |

| Run-out table (3M*2) | x1 set |

Working Process

Technical parameters

1.Matching material: color plate,Galvanized steel,Aluminum.

2.Material thickness range: 0.5-1mm

3.Main motor power: 5.5kw

4.Forming speed: 10-15m/min

5.Hydraulic power: 3.0kw

6.Quantity of stands: about 15

7.Shaft Material and diameter: ¢40mm, material is 45# forge steel

8.Material Of the stations: A3 steel

9.Tolerance: 3m+/-1.0mm

10.Way Of Drive: 1.0 inch single chain driving

11.Controlling system: PLC system

12.Voltage: 220V/ 3phase/ 60 Hz

13.Size of the roll forming machine: about 5m*1.0m*1.5 (L*W*H)

Rolling shutter door roll forming machine is a specialized piece of equipment used in the manufacturing of rolling shutter doors. These machines are designed to shape and form metal sheets into the desired profiles that make up the slats of rolling shutters. The process involves feeding metal coils into the machine, which then rolls and shapes the material through a series of rollers to create the final product. This type of machine is essential for producing durable and secure rolling shutters commonly used in commercial and industrial applications.

Using a rolling shutter door roll forming machine offers several advantages, including:

- Efficiency: These machines can produce large quantities of rolling shutter components quickly and consistently, reducing production time and labor costs.

- Customization: Manufacturers can easily adjust the machine settings to create various profiles and sizes, allowing for tailored solutions to meet specific customer needs.

- Quality Control: The automated nature of roll forming ensures high precision and uniformity in the final products, leading to better quality control and reduced waste.

- Durability: The materials processed through these machines are typically robust and long-lasting, making them ideal for security applications.

By investing in a rolling shutter door roll forming machine, businesses can enhance their production capabilities and offer high-quality products to their clients.