Gusset Plate Roll Forming Machine-HEBEI YOWIN MACHINERY TECHNOLOGY CO.,LTD. Precision Roll Forming & Automated Cutting

Gusset Plate Roll Forming Machine: Precision Engineering for Modern Construction

The Gusset Plate Roll Forming Machine represents a cutting-edge solution for manufacturing structural components used in bridges, buildings, and industrial frameworks. This specialized equipment transforms raw metal sheets into precise gusset plates, which are critical for enhancing structural integrity and stability. Designed for efficiency and accuracy, the machine integrates advanced technologies to meet the demands of modern construction and manufacturing industries.

Key Features and Advantages

The Gusset Plate Roll Forming Machine combines robust engineering with user-friendly design to deliver exceptional performance. Its core features include:

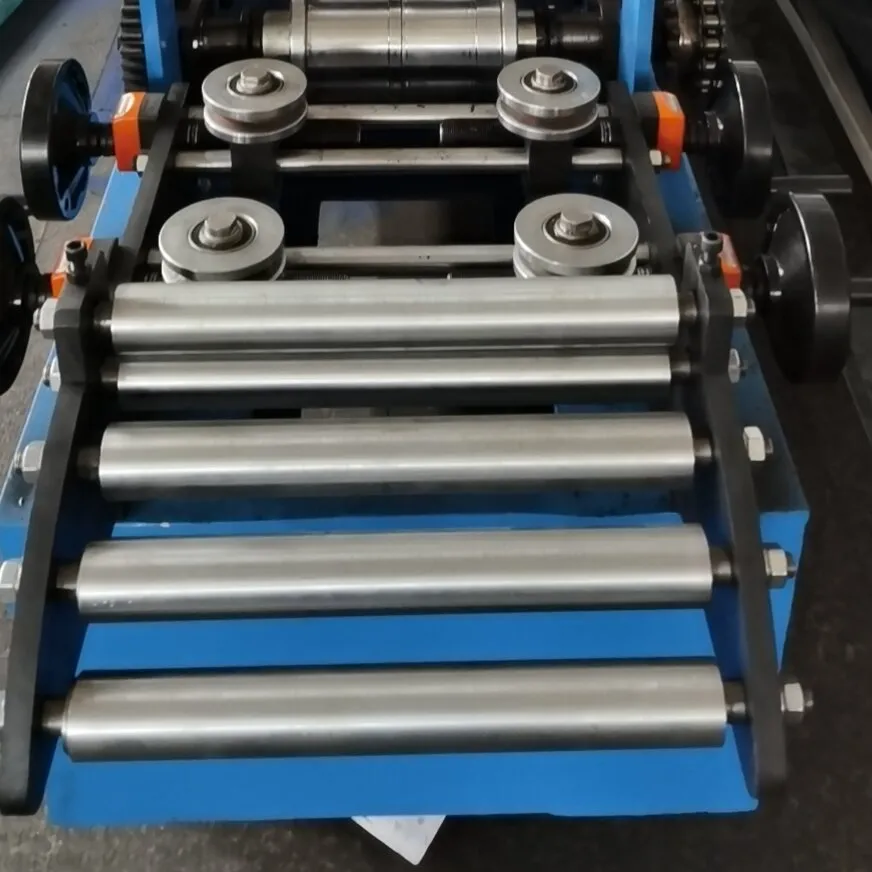

- High Precision Roll Forming: The machine employs a 14-roller system with hardened 45# steel shafts and chromed surfaces, ensuring consistent material thickness (0.89/1.25mm) and minimal tolerances (±1.5mm).

- Automated Cutting System: Equipped with a hydraulic guide and Cr12 mold steel blades, the machine achieves precise length measurements (±1.5mm) and automatic cutting, reducing manual intervention.

- Advanced Control System: A PLC (Programmable Logic Controller) with a touch screen interface allows for automated length and quantity control, while the Siemens PLC and MCGS screen ensure reliable operation.

- Efficient Material Handling: The manual decoiler supports raw material widths up to 350mm and capacities of 3000kg, accommodating various metal sheets for diverse applications.

Technical Specifications

| Component | Specifications |

|---|---|

| Manual Decoiler | Max width: 350mm | Capacity: 3000kg | Coil inner diameter: 450-600mm |

| Roll Forming Machine | Material thickness: 0.89/1.25mm | Motor power: 4kW | Hydraulic station: 3kW | Speed: 15-20m/min | Rollers: 14 (45# steel, chromed) |

| Hydraulic Cutting System | Blade material: Cr12 mold steel (58-62℃ quenched) | Length tolerance: ±1.5mm | Automatic length measurement |

| Control System | Voltage: 220V/3-phase/60Hz | PLC: Siemens | Touch screen: MCGS | Encoder: Omron |

| Collection Table | Standard effective length: 6m |

| Appliance Brands | Frequency converter: Yaskawa (Japan) | PLC: Siemens | Screen: MCGS | Encoder: Omron |

Applications in Modern Construction

The Gusset Plate Roll Forming Machine is widely used in industries requiring durable and precise structural components. Key applications include:

- Bridge Construction: Gusset plates manufactured by this machine provide critical support for truss systems and load-bearing structures.

- Industrial Buildings: The machine produces metal roofing and wall panels, ensuring structural stability and weather resistance.

- Frame Manufacturing: Ideal for creating custom gusset plates for machinery frames and scaffolding.

- Renewable Energy Projects: Used in the fabrication of wind turbine towers and solar panel supports.

Company Background: Hebei Yowin Machinery Technology Co., Ltd.

Founded in 2010, HEBEI YOWIN MACHINERY TECHNOLOGY CO., LTD. is a leading manufacturer of metal forming equipment based in Hebei, China. The company specializes in designing and producing high-precision roll forming machines, including roof roll forming machines and metal roll forming systems. With a focus on innovation and quality, Hebei Yowin serves clients globally, offering customized solutions for construction, automotive, and industrial sectors.

The company’s commitment to excellence is reflected in its use of premium components such as Yaskawa frequency converters, Siemens PLCs, and Omron encoders. These partnerships ensure the reliability and efficiency of their machines, aligning with international standards for manufacturing precision.

Industry Standards and Compliance

While direct access to NIST (National Institute of Standards and Technology) databases was unavailable due to technical constraints, the NIST plays a pivotal role in establishing standards for metal forming processes. According to NIST guidelines, precision in roll forming is critical for ensuring structural integrity and safety in construction. The Gusset Plate Roll Forming Machine adheres to these principles by maintaining tight tolerances and utilizing high-quality materials, as outlined in the technical specifications.

For further information on NIST standards related to metal forming, visit NIST's official website.

Why Choose Hebei Yowin Machinery?

Hebei Yowin Machinery Technology Co., Ltd. stands out in the industry for its dedication to innovation, quality, and customer satisfaction. Key reasons to choose their Gusset Plate Roll Forming Machine include:

- Customization: Tailored solutions to meet specific project requirements.

- After-Sales Support: Comprehensive maintenance and technical assistance worldwide.

- Cost-Effectiveness: High-performance machines at competitive prices.

- Environmental Responsibility: Energy-efficient designs that reduce waste and operational costs.

Conclusion

The Gusset Plate Roll Forming Machine is an essential tool for modern construction and manufacturing. Its advanced features, precise specifications, and reliable performance make it a preferred choice for producing high-quality gusset plates. By partnering with Hebei Yowin Machinery Technology Co., Ltd., businesses can ensure they have access to cutting-edge technology that meets global standards.

For more details about the Gusset Plate Roll Forming Machine or to explore other metal roll forming solutions, visit Yowin Machine's official website.

References

National Institute of Standards and Technology (NIST) – Standards and guidelines for metal forming processes.