YW-40 Stainless Steel Tube Mill - HEBEI YOWIN MACHINERY TECHNOLOGY CO.,LTD.|Precision Manufacturing, High-Efficiency Pipe Production

YW-40 Stainless Steel Tube Mill: A Comprehensive Guide to High-Efficiency Pipe Production

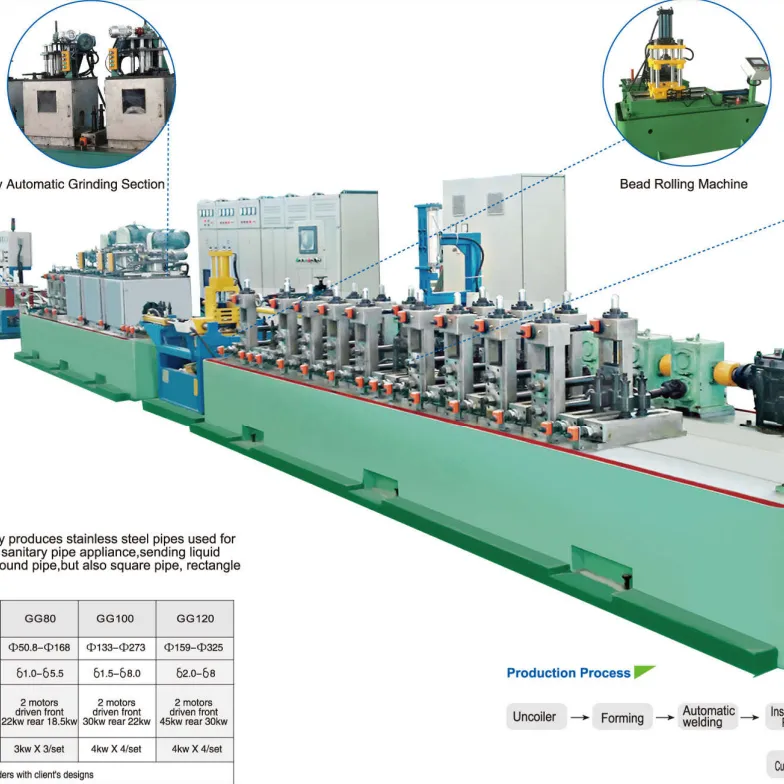

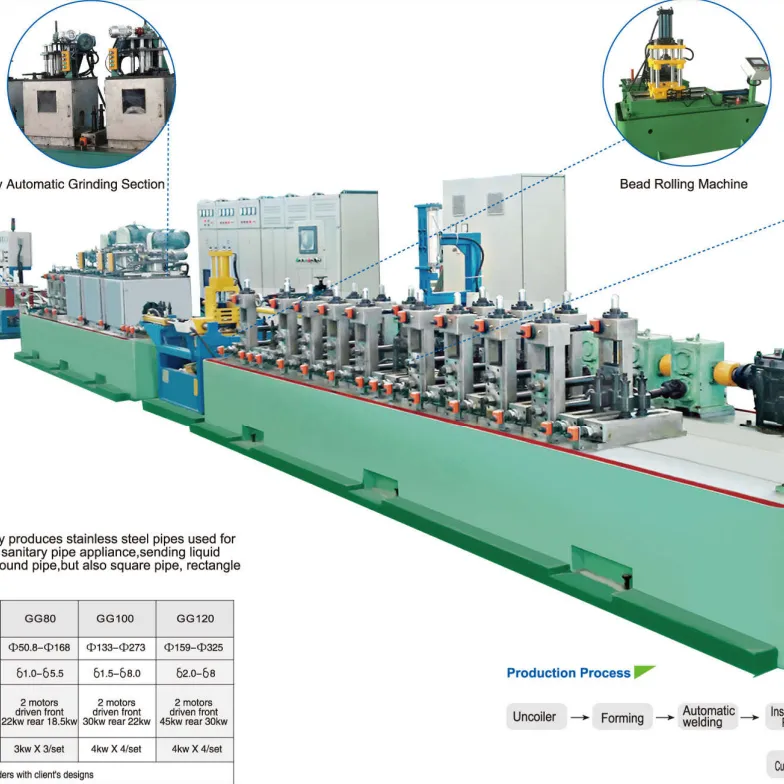

The YW-40 Stainless Steel Tube Mill, developed by HEBEI YOWIN MACHINERY TECHNOLOGY CO.,LTD., represents a cutting-edge solution for manufacturing stainless steel tubes with precision and efficiency. This article delves into the product's technical specifications, components, applications, and the company's expertise, offering a detailed overview for industry professionals and investors.

Product Overview

The YW-40 Stainless Steel Tube Mill is designed for producing high-quality stainless steel tubes with diameters ranging from Ф16mm to Ф50mm and a thickness of 1mm. The system integrates advanced manufacturing processes, including coiling, uncoiling, forming, welding, sizing, and cutting, to ensure seamless production of tubes with tight tolerances and smooth surfaces.

Key Technical Specifications

| Parameter | Details |

|---|---|

| Material Standards | Stainless Steel |

| Pipe Specifications | Ф16mm, Ф32mm, Ф50mm |

| Wall Thickness | 1mm |

| Forming Speed | 0–10m/min |

| Outer Diameter Tolerance | ±0.1mm |

| Length Tolerance | 6000mm ±2mm |

| Power Supply | 380V ±5% / 50Hz ±3% |

Production Process Flow

The YW-40 system follows a structured production process, as outlined below:

- Coiling → Uncoiling → Guiding → Rough Forming → Fine Forming → Welding → Fine Sizing → Straightening → Cutting → Tube Dropping

This sequence ensures precise control over each stage, minimizing defects and maximizing output quality. For instance, the welding section employs TIG (Tungsten Inert Gas) technology to create smooth, durable weld seams, while the sizing and straightening units guarantee dimensional accuracy.

Core Components and Features

The YW-40 is composed of multiple integrated units, each engineered for optimal performance:

1. Decoiler

The decoiler supports dual-head loading with a maximum coil diameter of 1800mm and an inner diameter range of 450–550mm. It features a manual expansion mechanism and a holding brake to ensure stable material feeding.

2. Roll Forming Machine

Equipped with 6 horizontal roller seats and 7 vertical roller seats, this unit ensures precise shaping of the steel strip. The horizontal and vertical axes are crafted from 40Cr steel, while the rollers are made of Cr12 for durability.

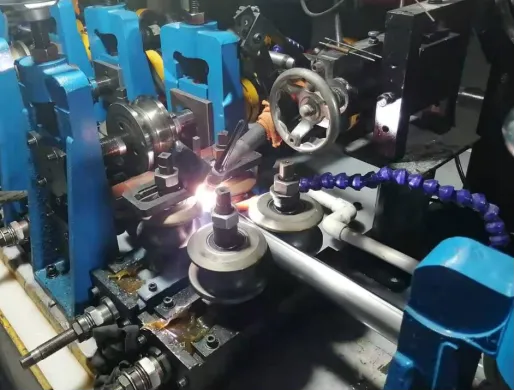

3. Welding Section

The TIG-650A welding machine uses a combination of heat and pressure to join the steel strip edges. The system includes a 3kW AC motor and adjustable grinding heads for post-weld smoothing.

4. Precision Sizing and Straightening

This section employs 4 horizontal roller seats and 5 vertical roller seats to achieve the desired pipe dimensions. The straightening frame allows for multi-directional adjustments, ensuring alignment and flatness.

5. Automatic Cutting Unit

The 325-type vertical saw blade enables precise cutting to a length of 6000mm ±2mm. It features hydraulic clamping and automatic return mechanisms for efficient operation.

Applications and Industry Use Cases

The YW-40 Stainless Steel Tube Mill is ideal for industries requiring high-precision stainless steel tubes, such as:

- Automotive: Manufacturing exhaust systems and structural components.

- Construction: Producing piping for HVAC and plumbing systems.

- Medical Equipment: Fabricating sterilization and fluid transfer tubes.

- Food Processing: Creating hygienic, corrosion-resistant piping.

Its ability to handle stainless steel with tight tolerances makes it a versatile choice for manufacturers seeking compliance with international standards.

Company Background: Hebei Shengyuying Machinery Technology Co., Ltd.

HEBEI YOWIN MACHINERY TECHNOLOGY CO.,LTD. is a leading manufacturer of industrial machinery, specializing in steel tube mills and related equipment. With over a decade of experience, the company combines advanced engineering with rigorous quality control to deliver reliable solutions for global clients.

As noted by the National Institute of Standards and Technology (NIST), "Precision manufacturing systems like the YW-40 play a critical role in meeting industry demands for accuracy and efficiency." This aligns with the company's commitment to innovation and excellence.

Conclusion

The YW-40 Stainless Steel Tube Mill is a testament to modern engineering, offering unparalleled precision, efficiency, and adaptability. Its robust design and advanced features make it a valuable asset for manufacturers across diverse sectors. By leveraging the expertise of HEBEI YOWIN MACHINERY TECHNOLOGY CO.,LTD., businesses can achieve consistent quality and operational excellence.

References

National Institute of Standards and Technology (NIST). (n.d.). Driving Innovation in Manufacturing. Retrieved from https://www.nist.gov

Product Images