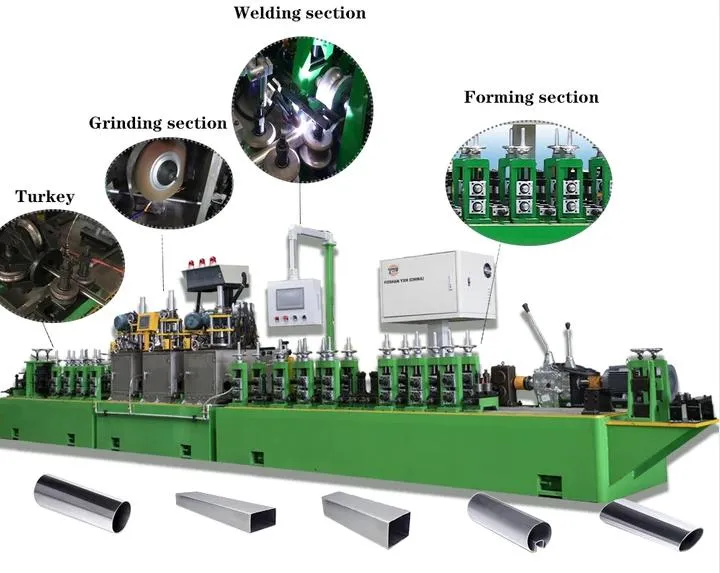

Production technology process:

Flow chat:vHvHvHvvvHvHvH SQSQ MvMvM HvHvHvHvTZTZv

Remarks: V represents horizontal support, H represents vertical support,

M represents grinding seat, TZ represents Türkiye head

Coiling→uncoiling→Guiding→Rough Forming→Fine Forming→ welding→Fine Sizing→Straightening→cutting→Tube dropping

Composed devices for each line:

|

1.Decoiler |

1sets |

|

2.Feeding and roll forming parts:vHvHvHvvvHvHvH |

|

|

A.Feeding guide wheel |

1sets |

|

B.Forming horizontal roller seat |

6 sets |

|

C.Forming vertical roller seat |

7 sets |

|

D.Transmission system (drive motor+gearbox+turbine gearbox+transmission shaft) |

1 set |

|

E. Cooling system (water pipe+spray pipe) (customer provided circulating water tank water pump) |

1 set |

|

F. Electrical cabinet placement platform |

1 set |

|

G. Box base |

1 set |

|

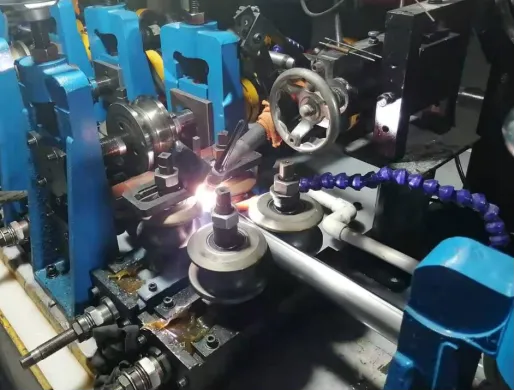

3.Welding part:vvH |

|

|

A.Welding vertical roller seat |

2 sets |

|

B.Welding horizontal roller seat |

1 set |

|

C.Welding gun bracket |

1 set |

|

D. Welding machine placement platform |

1 set |

|

E. Box base |

1 set |

|

F. Welding machine |

1 set |

|

4.Polishing section: MvMvM |

|

|

A.Polishing head |

3 sets |

|

B.Vertical roller seat |

2 sets |

|

C.Cooling system (water pipe+spray pipe) (customer provided circulating water tank water pump) |

1 set |

|

5.Precision sizing section+straightening section: HvHvHvH TZ1 TZ12v |

|

|

A.Precision sizing horizontal arm |

4 sets |

|

B.Precision sizing vertical roller seat |

3 sets |

|

C.Transmission system (drive motor+gearbox+turbine gearbox+transmission shaft) |

1 set |

|

D. Cooling System (Water Pipe+Spray Pipe) (User made Water Tank Pump) |

1 set

|

|

E. Box base |

1 set |

|

F. Straightening frame |

2 sets |

|

6.325 type vertical saw blade cutting table |

1 set |

|

7.Unloading rack |

1 set |

|

8.Electrical Control System (Mechanical) |

1 set |

|

9.Random accessories: spacer, foot screw, shim, faucet, etc |

1 set |

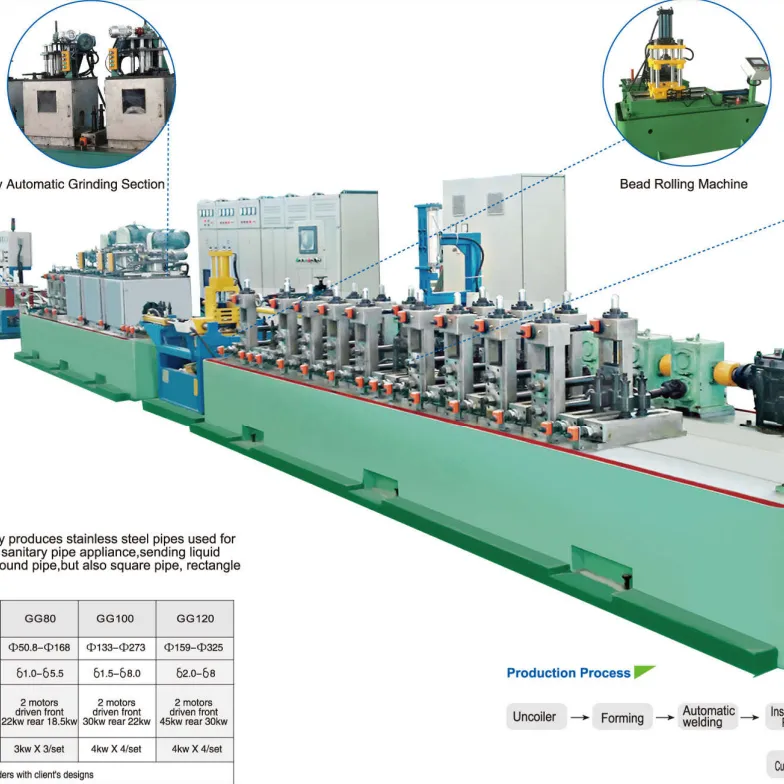

Main parameter:

|

Material Standards for Pipe Manufacturing: |

stainless steel |

|

Pipe specification: |

Pipe:Ф16mm,Ф32mm,Ф50mm |

|

Pipe thickness: |

1mm |

|

Forming speed: |

0m—10m/min |

|

Material limitations: |

A:ID:Ф450-520mm |

|

B:OD:Ф1800mm max |

|

|

C Width:max160mm |

|

|

D:weight:1800kg max |

|

|

Pipe length: |

6m |

|

Outer diameter tolerance: |

±0.1mm |

|

length tolerance: |

6000mm±2mm |

|

Outer weld seam: |

Polish smooth |

|

inside weld |

Not handled |

|

Main voltage of production line: |

380V±5%V/3 50HZ±3%HZ |

|

Control voltage of production line: |

220V±5%V/2 50HZ±3%HZ |

|

operation direction: |

To be determined and confirmed in the contract |

|

Color |

To be determined and confirmed in the contract |

Detailed configuration instructions:

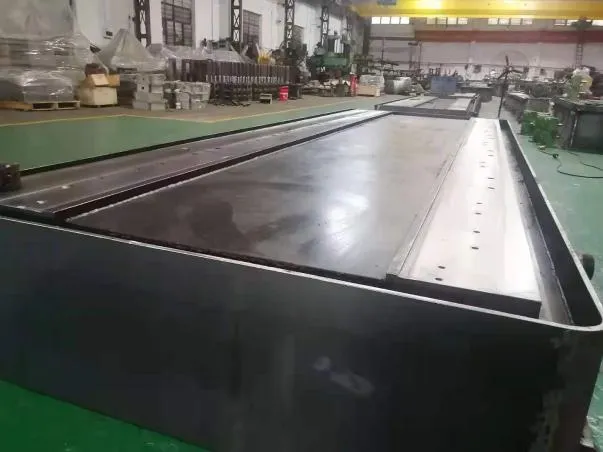

1.Unit base

1.1.Structure: The main chassis panel has a longitudinal tile shaped structure, which avoids the soft state of large flat panels and increases strength to prevent deformation. Steel ensures the high strength of the unit foundation and prevents deformation in the later stages of use. Improve the long-term accuracy of the unit. The transmission machine base and the main machine base are of a separate structure.

1.2.Material: Base panel steel plate: 25mm, side panel: 10mm, inner lining reinforcement plate: 8mm.

2.Decoiler

3.Roll forming machine

4.Welding TIG-650A

5.Grinding of external welds

6.Precision sizing and straightening

7.Automatic cutting unit

8.Unloading rack

9.Electronic control system

10.Rollers

|

10.1. Material: cr12mov 10.2. Manufacturing process: refined bar material - blanking - rough turning - CNC finishing - vacuum quenching - wire cutting keyway - secondary finishing hole - inspection - marking - packing Hardness: HRC60°~ 63°. The mold does not contain bearings |