Portable Standing Seam Roll Forming Machine-Yowin Machinery|Portable Metal Roofing Production&High-Precision Roll Forming

Portable Standing Seam Roll Forming Machine: Advanced Solutions for Modern Construction

Discover the Portable Standing Seam Roll Forming Machine, a cutting-edge solution designed to revolutionize metal roofing production. Developed by HEBEI YOWIN MACHINERY TECHNOLOGY CO.,LTD., this machine combines portability, precision, and efficiency to meet the demands of modern construction projects. In this article, we explore its technical specifications, applications, and the company's commitment to innovation.

Product Overview

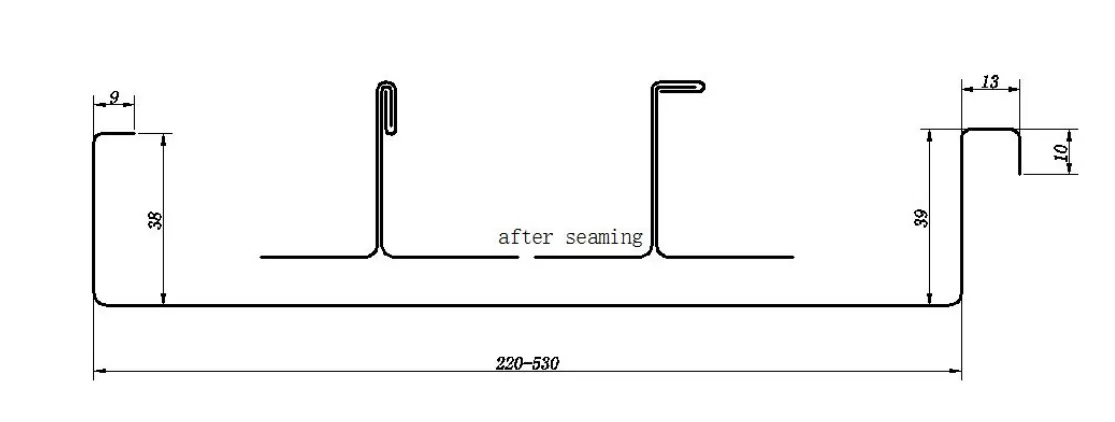

The Portable Standing Seam Roll Forming Machine is engineered to produce high-quality standing seam roofing sheets with exceptional speed and accuracy. Its compact design and lightweight construction make it ideal for on-site operations, reducing the need for extensive infrastructure. The machine's ability to handle materials with a thickness range of 0.4-1.0mm, including galvanized steel (GI) and cold roll steel (CRC), ensures versatility across various projects.

Product image: Portable Standing Seam Roll Forming Machine

Key Features and Advantages

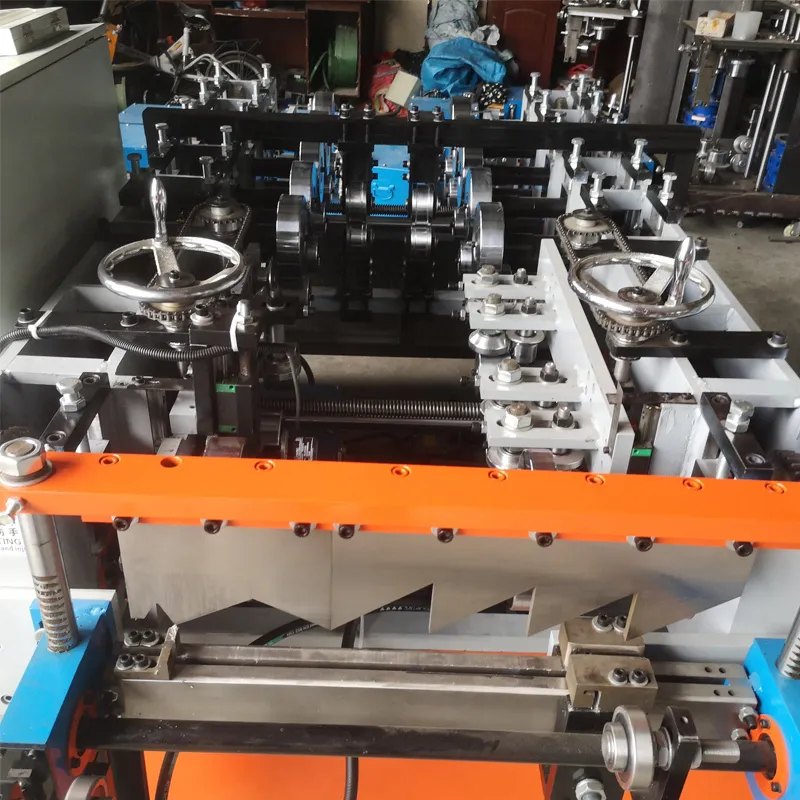

The machine's standout features include its PLC control system, hydraulic cutting mechanism, and modular design. These elements work in harmony to deliver consistent results while minimizing downtime. Below are the core advantages:

- Portability: Weighing approximately 1.5 tons and measuring 2500×1200×1400mm, the machine is easy to transport and set up on-site.

- High Precision: The 8-roller system with chromed 45# steel rollers ensures accurate shaping of metal sheets.

- Automated Control: The PLC system enables automatic length and quantity measurement, reducing human error and increasing productivity.

- Durability: Components like the Cr12 mold steel cutting blades (58-62℃ quenched) and 40Cr shafts (45mm diameter) ensure long-term reliability.

Technical Specifications

| Parameter | Details |

|---|---|

| Material Thickness | 0.4-1.0mm |

| Applicable Materials | Galvanized Steel (GI), Cold Roll Steel (CRC), Yield Strength 345-550MPa |

| Main Motor Power | 4kW |

| Hydraulic Station Power | 3kW |

| Speed Range | 0-15m/min |

| Number of Rollers | 8 (45# steel, chromed) |

| Shaft Material and Diameter | 40Cr, 45mm |

| Cutting Blade Material | Cr12 mold steel (58-62℃ quenched) |

| Weight | Approx. 1.5 tons |

| Dimensions | 2500×1200×1400mm |

Working Process and Components

The machine operates through a seamless workflow, starting with the de-coiler unrolling the metal coil, followed by the roll forming machine shaping it into the desired profile. The hydraulic cutting system ensures precise length measurement and automatic cutting, while the PLC control system manages all operations. A run-out table (3M×2) facilitates smooth material discharge.

Process diagram: De-coiler → Roll forming → Hydraulic cutting → PLC control

Applications

The Portable Standing Seam Roll Forming Machine is ideal for a wide range of applications, including:

- Commercial and industrial roofing projects

- Residential construction with high aesthetic requirements

- Renovation and retrofitting of existing structures

- Temporary or remote site operations

Its ability to produce standing seam profiles with minimal waste makes it a preferred choice for environmentally conscious builders.

Company Background

HEBEI YOWIN MACHINERY TECHNOLOGY CO.,LTD. is a leading manufacturer of metal forming machinery, specializing in innovative solutions for the construction and manufacturing industries. With a focus on quality and customer satisfaction, the company has earned a reputation for delivering reliable equipment that meets global standards.

Company logo: HEBEI YOWIN MACHINERY TECHNOLOGY CO.,LTD.

Industry Standards and Compliance

While the Portable Standing Seam Roll Forming Machine is not explicitly certified by NIST, the principles of precision and reliability it embodies align with the standards upheld by the National Institute of Standards and Technology. NIST's role in developing measurement standards for manufacturing processes underscores the importance of such technologies in ensuring product consistency and safety [1].

Business Terms and Support

- Warranty: 12 months from delivery

- Payment Terms: 30% deposit, 70% balance before shipping

- Production Time: 30 days

- Installation Policy: Customers cover engineer costs (round-trip air tickets, accommodation, $100/day)

Conclusion

The Portable Standing Seam Roll Forming Machine by HEBEI YOWIN MACHINERY TECHNOLOGY CO.,LTD. is a testament to the power of innovation in modern manufacturing. Its combination of portability, precision, and durability makes it an indispensable tool for construction professionals. By adhering to industry best practices and leveraging advanced technology, Yowin Machinery continues to set new benchmarks in the metal forming sector.

References

[1] National Institute of Standards and Technology (NIST) - Research and standards for manufacturing processes.

Product image: Portable Standing Seam Roll Forming Machine

Product image: Hydraulic Cutting System

Product image: PLC Control Panel