C/Z Purlin Roll Forming Machine-HEBEI YOWIN MACHINERY|Precision Steel Forming, Adjustable Dimensions

Yowin C/Z Purlin Roll Forming Machine: Precision Engineering for Industrial Applications

Yowin, a leading manufacturer in the field of metal forming machinery, presents its C/Z Purlin Roll Forming Machine, a cutting-edge solution designed to meet the evolving demands of the construction and manufacturing industries. This machine combines advanced technology with robust engineering to deliver high-quality purlins and zee sections efficiently and reliably. Below, we explore the product's features, technical specifications, applications, and the company's commitment to innovation.

Product Overview

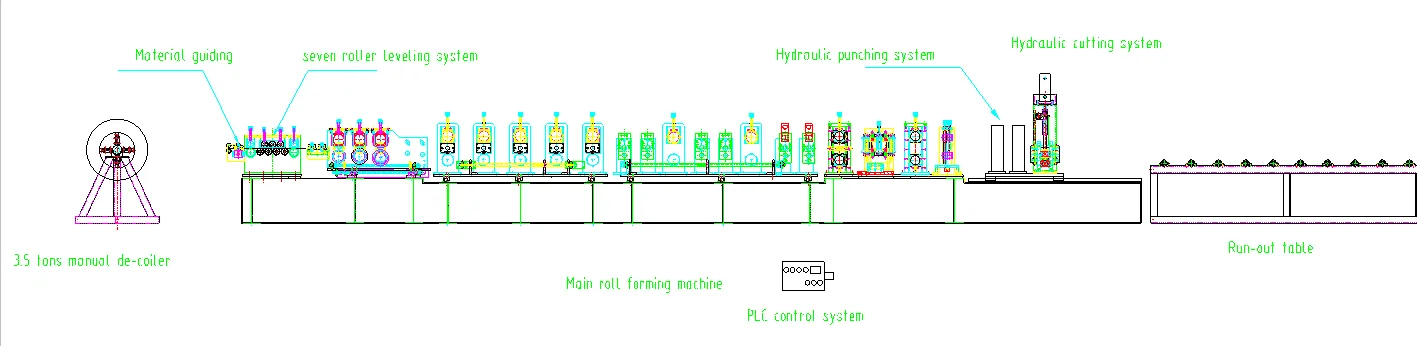

The Yowin C/Z Purlin Roll Forming Machine is a comprehensive system that streamlines the production of cold-formed steel purlins and zee sections. It integrates multiple components, including a passive uncoiler, feed guide, leveling device, and hydraulic punching system, to ensure seamless operation and precision. The machine's modular design allows for easy adjustments, making it suitable for a wide range of applications.

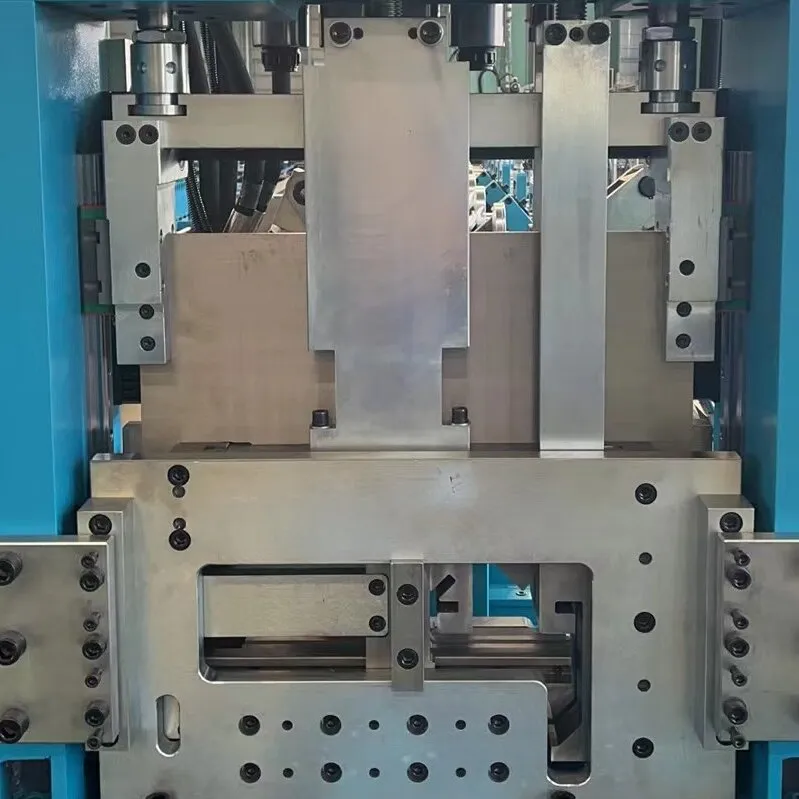

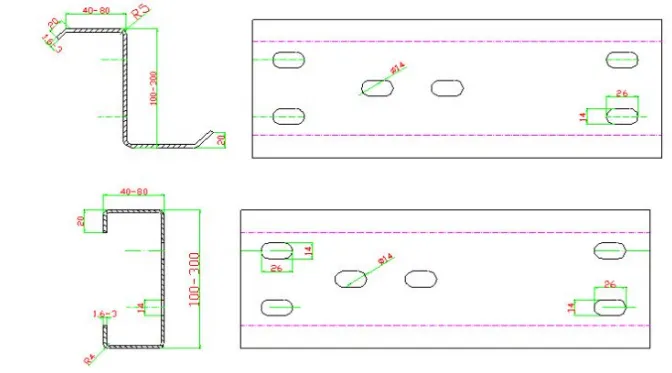

Figure 1: Product Drawing of Yowin C/Z Purlin Roll Forming Machine

Key Components and Features

The machine comprises several critical components, each engineered to enhance performance and durability:

- Passive Uncoiler: Capable of handling up to 5 tons of material, this component ensures smooth feeding of steel coils. It features a hand-cranking mechanism and four-link center outward bracing for stability.

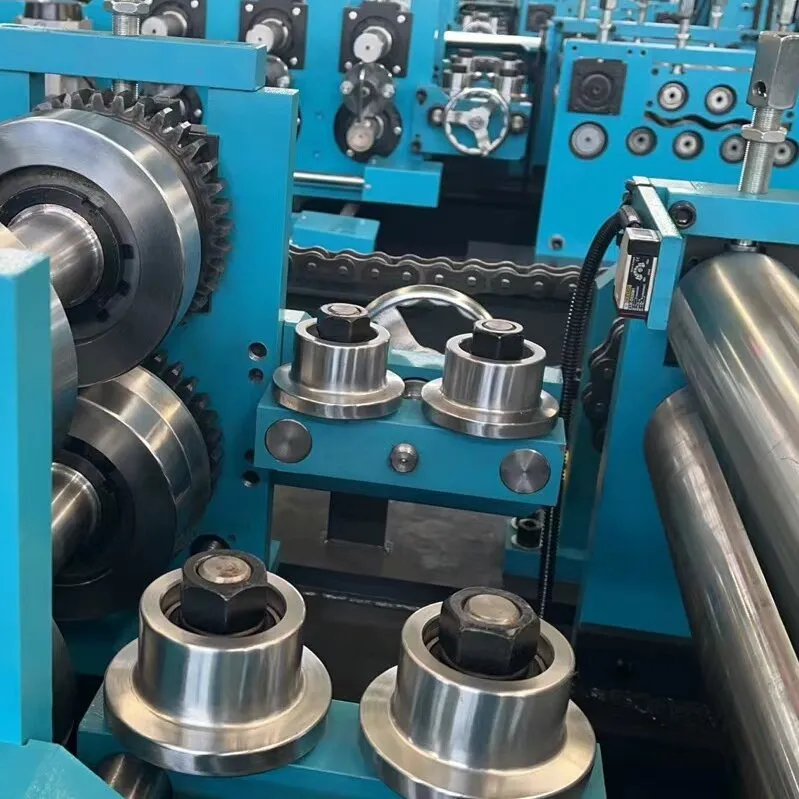

- Feed Guide: Equipped with a shaft and guide wheel system, the feed guide ensures accurate alignment of the steel strip during processing.

- Leveling Device: This device uses a three-roll and four-roll configuration with a solid spindle, heat-treated and polished for precision. It ensures the steel strip is free from distortions before forming.

- Main Forming Machine: The heart of the system, this component can produce C and Z sections with adjustable dimensions. It features 18 composition types, including a waist height forming group, and 13 CZ exchange modules for flexible production.

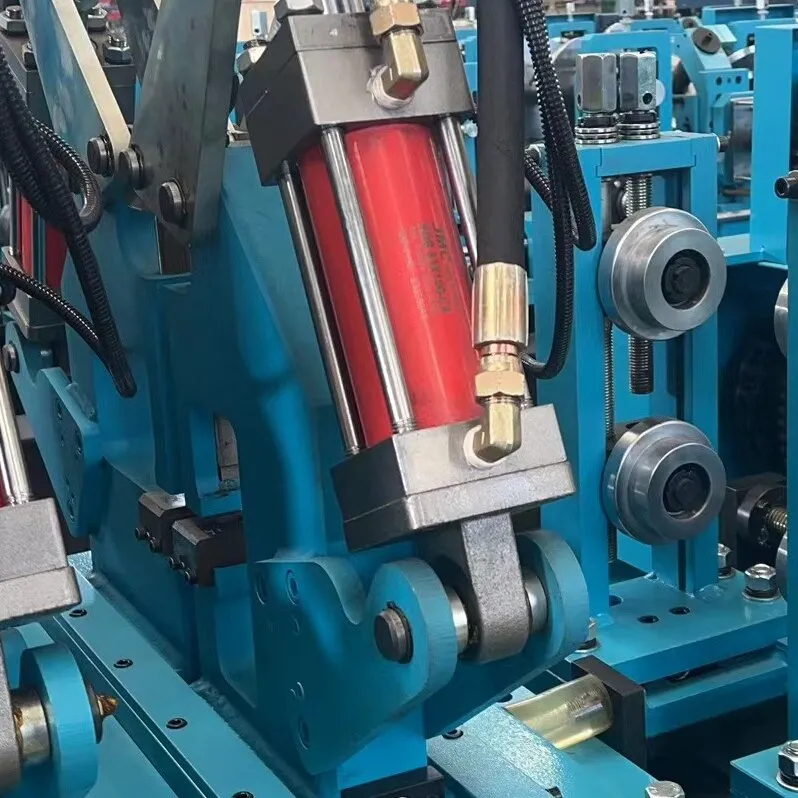

- Hydraulic Punching System: Capable of single and double hole punching, this system uses round and oval holes of varying sizes to meet specific design requirements.

- Hydraulic Cutting System: A stepless shearing system ensures precise cutting of finished products. It utilizes Taiwan Shangyin linear tracks for stability and ease of adjustment.

- PLC Control System: The machine is equipped with a PLC (Omron or Wuxi Xinjie) and a touch screen interface, enabling intuitive operation and real-time monitoring.

- Hydraulic Station: With a 22KW power rating and a 350L fuel tank, the hydraulic station ensures consistent pressure for all operations.

- Receiving Table: Designed with galvanized passive rollers, the receiving table protects the finished product's surface and supports lengths of 3 meters.

Figure 2: Flow Chart of the Roll Forming Process

Technical Specifications

| Component | Specifications |

|---|---|

| Passive Uncoiler | Capacity: 5 tons; Bracing Method: Hand cranking, four link center outward bracing; Brake: Double locking of main shaft |

| Feed Guide | Shaft + Guide Wheel System |

| Leveling Device | Upper three lower four + two lead; Solid spindle with heat treatment and electroplating |

| Main Forming Machine | Width Range: C (80-300 mm), Z (120-300 mm); Waist Height: 40-80 mm; Plate Thickness: 1.5-3.0 mm; Roll Material: GCr15; Shaft Material: 40Cr |

| Hydraulic Punching | Round Holes: Φ14mm, Φ16mm; Oval Holes: 26×16mm, 26×14mm |

| Hydraulic Cutting | Stepless Shearing System; Adjustable Cutting for C/Z Sections (80-300 mm) |

| PLC Control System | PLC (Omron or Wuxi Xinjie), Touch Screen, Relay, Proximity Switch, Length Encoder |

| Hydraulic Station | Power: 22KW; Fuel Tank: 350L; Solenoid Valve: Beijing Huade |

| Receiving Table | 3m × 2 pieces; Galvanized Passive Rollers |

Applications and Industry Use Cases

The Yowin C/Z Purlin Roll Forming Machine is widely used in various industries, including:

- Construction: Production of roof and wall purlins for steel structures, ensuring lightweight and durable solutions.

- Manufacturing: Custom fabrication of Z-sections for industrial equipment and machinery.

- Automotive: Manufacturing of structural components requiring high precision and strength.

- Infrastructure: Fabrication of beams and supports for bridges and highways.

Figure 3: Key Components of the Machine

Company Background: HEBEI YOWIN MACHINERY TECHNOLOGY CO., LTD.

Based in Hebei, China, HEBEI YOWIN MACHINERY TECHNOLOGY CO., LTD. is a trusted manufacturer of metal forming machinery. With a focus on innovation and quality, Yowin has established itself as a leader in the industry, providing solutions that meet global standards. The company's commitment to research and development ensures that its products, like the C/Z Purlin Roll Forming Machine, are at the forefront of technological advancements.

Figure 4: Advanced Engineering of the Machine

Why Choose Yowin?

Yowin's C/Z Purlin Roll Forming Machine offers several advantages:

- Flexibility: Adjustable dimensions and modular design allow for quick changes in production.

- Efficiency: High-speed operation (up to 2m/min) and automated systems reduce downtime.

- Durability: High-quality materials and precision engineering ensure long-term reliability.

- Cost-Effectiveness: Reduced material waste and energy consumption contribute to lower operational costs.

Industry Standards and Certifications

Yowin adheres to international standards for manufacturing and safety. The machine's design incorporates principles of precision and reliability, aligning with guidelines from organizations like the National Institute of Standards and Technology (NIST), which emphasizes the importance of metrology in industrial processes. According to NIST, "Precision measurements are critical for ensuring the quality and consistency of manufactured products" (NIST, 2025). Yowin's commitment to accuracy reflects this principle, ensuring that every purlin meets exacting specifications.

Figure 5: Hydraulic and Drive Components

Conclusion

The Yowin C/Z Purlin Roll Forming Machine exemplifies the synergy of advanced technology and robust engineering. With its versatile design, precision, and efficiency, it is an ideal choice for manufacturers seeking to enhance productivity and product quality. By choosing Yowin, businesses gain access to a reliable partner in the ever-evolving landscape of industrial manufacturing.

References

NIST (National Institute of Standards and Technology). (2025). https://www.nist.gov/

Yowin Machinery Technology Co., Ltd.. (n.d.). https://www.yowinmachine.com

Product Gallery