I.Technical Parameter:

|

Steel coil parameters |

Control model |

PLC Frequency conversion control |

|

Material |

CR,HR |

|

|

Yield strength |

≤550mPa |

|

|

Steel thickness

|

0.5-3mm |

|

|

Steel width |

500-1700mm(Max) |

|

|

Steel coil I.D |

Φ508mm(480-520mm) |

|

|

Steel coil O.D |

≤Φ1600mm(Max) |

|

|

Steel coil weight |

≤20T |

|

|

Slitter parameters |

knife pivot diameter |

Ф200 mm |

|

Knife pivot material |

40Cr |

|

|

Blades specification |

Φ200mmXφ340mmX14mm |

|

|

Blade material |

H13K |

|

|

Slit parameter |

Max slit quantity |

5pcs(3mm) 8pcs(2mm) 15pcs(1mm) 30 pcs(0.5mm) |

|

Width precision |

≤±0.1mm |

|

|

Min strips width |

30mm |

|

|

Recoiler parameter

|

Recoiler ID |

Φ508mm |

|

Recoiler coil weight |

≤15T |

|

|

Other parameters |

Power |

380V/50Hz/3Ph |

|

Line speed |

30-60m/min |

|

|

Capacity |

About 180 Kw |

|

|

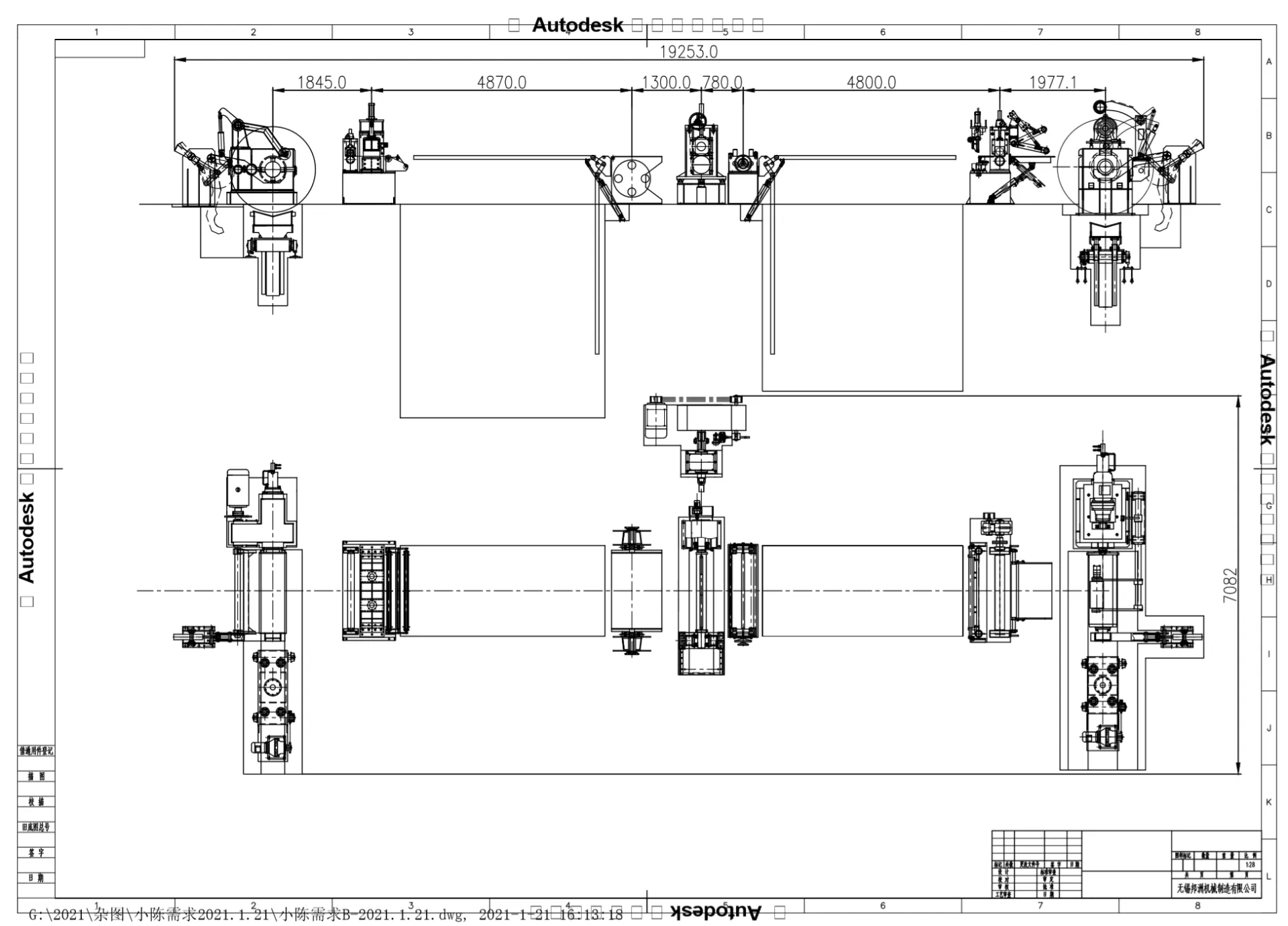

Whole line Dimension |

About 23m(L)X8m(W) |

|

|

Operator needed |

1 mechanical engineer ,2 common workers |

|

|

Line direction |

From right to left(Face to machine) |

|

|

Machine color |

Blue |

II. The flow of the process

From right to left, Uncoiler + coil car—Press and pinch device+Head cutter —Side guide device + slitter + Scrap winder—Tension stand—Recoiler +coil car

III. Composed devices

|

No |

Name |

Quantity |

|

1 |

Hydraulic entry coil car |

1set |

|

2 |

Hydraulic de-coiler |

1 set |

|

3 |

Hydraulic press and pinch device |

1 set |

|

4 |

Cutter |

1 set |

|

5 |

Looper1 |

1 set |

|

6 |

Side guide device |

1 set |

|

7 |

Slitting machine |

1 set |

|

8 |

Scrap winder |

1 set |

|

9 |

Looper2 |

1 set |

|

10 |

Tension stand |

1 set |

|

11 |

Recoiler |

1set |

|

12 |

Hydraulic exit coil car |

1set |

|

13 |

Hydraulic system |

1 set |

|

14 |

Electrical control system |

1 set |

IV、Brief instruction

1.Hydraulic entry coil car

◆The car can move levelly and vertically, which is convenient for putting the steel coils into the de-coiler.

◆It is driven vertically by hydraulic cylinder with four guide pillars.

◆The level movement is driven by cycloid motor.

◆The capacity of it can reach to 20Tons(MAX)

◆Function: It is used to lift up and down, move forward and back to make it easy to load the coils on decoiler. Hydraulic controls lifting, motor drives moving. The car is controlled on the auxiliary control panel. Its moving speed is 6-7m/min. When the coils on decoiler, the car will return back to the start position. It can also carry back the unfinished coils from decoiler.

Hydraulic head cutter

◆Adopt double type structures, can cut the 3mmX1700 steel plates.

◆Blades are H13K material and the up and down clearances is adjustable.

◆This device is used to shear the head of coils and make the material go through the slitter very conveniently, and it can also be used to cut the big coils into the small coils.

Loop I

◆The roller-table lift up and down by hydraulic.

◆The size of the pit: 3500mm(L)x2000mm(W)x4000mm(D)

|

Item |

Parameters and details |

Note |

|

Power |

55KW AC |

|

|

Shaft |

Φ200 |

|

|

Material of shaft |

40Cr |

|

|

Blade specification |

Φ340×Φ200×15 |

Loop II

◆The roller-table lift up and down by hydraulic.

◆The size of the pit: 3500mm(L)x2000mm(W)x4500mm(D)

Hydraulic exit coil car

◆The car can move levelly and vertically, which is convenient for putting the steel coils into the de-coiler.

◆It is driven vertically by hydraulic cylinder with four guide pillars.

◆The level movement is driven by cycloid motor.

◆The capacity of it can reach to 15tons(MAX)

Hydraulic system

◆Composed of hydraulic oil pump, pipes, connectors, etc

◆Ensure the use of every hydraulic part.

Electrical control system

◆It controls the speed of the whole line. The main operation table can make the whole line change from high to low speed. And it can also make the plate into the machine manually.