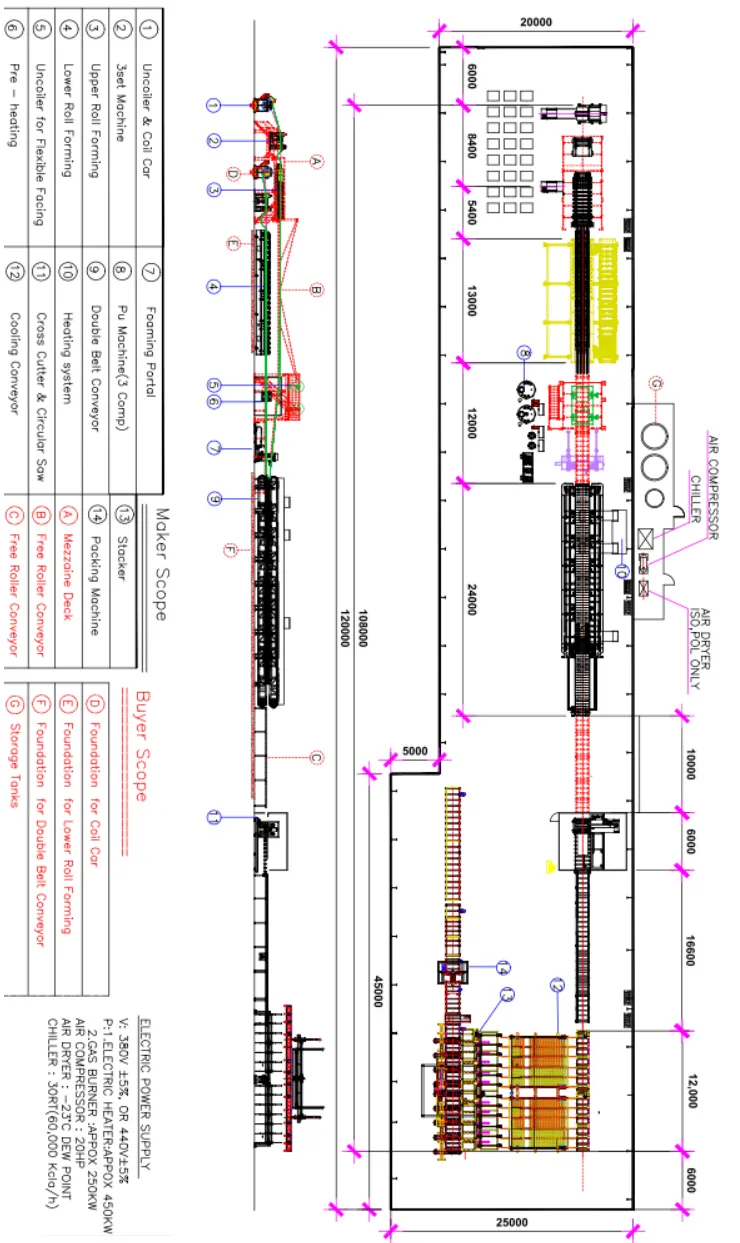

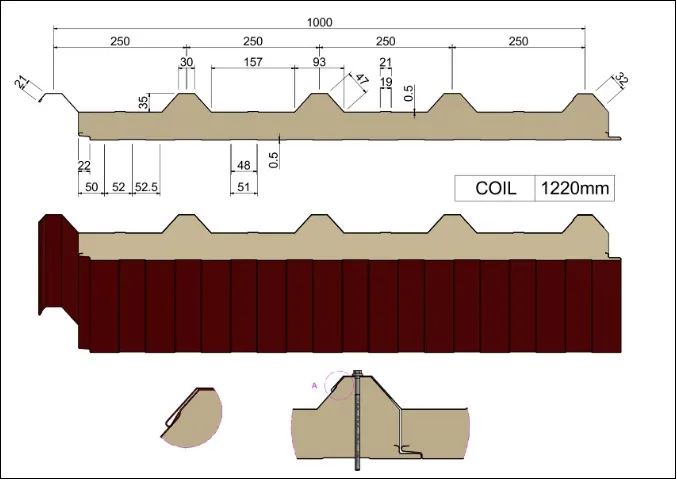

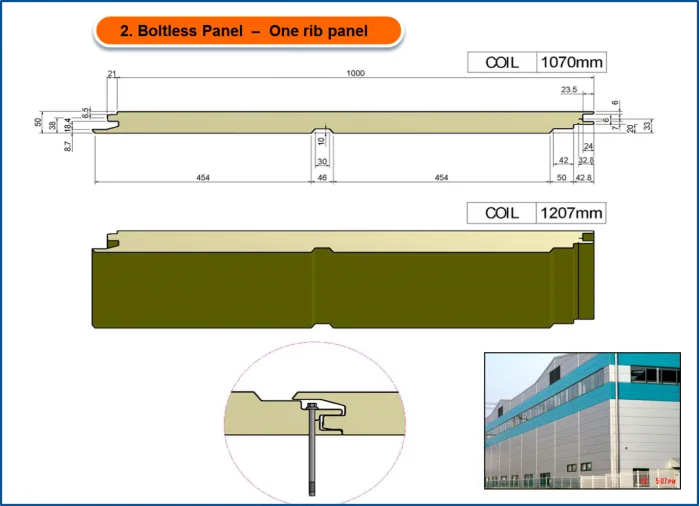

Drawings

Component

| No | Parts & Description | Q’ty |

| A. Roll Forming Line | ||

| 1 | Coil Car and Uncoiler for Upper and Lower (Max. 10 ton) | 2sets |

| - Hydraulic type | ||

| 2 | 3 sets machines for Top and Bottom | 2 sets |

| - Pinch roll/ Shearing | ||

| - Protect film coating device for Top & Bottom facing. | ||

| - 2 sets grooving rolls (Micro and Wide) for Top & Bottom | ||

| 3 | Corona system (Bottom side only) | 1 set |

| 4 | Top Roll Forming machine for | 1 unit |

| - Width fixed type (1,000mm) | ||

| 5 | Roll Forming machines for lower | |

| - Cold Room panel-12 stages | 1 set | |

| - Roof (4 Rib/ 35-250) 24 stages | 1 set | |

| - Boltless panel (Hidden fix) 18 stages | 1 set | |

| 6 | Traverse System by Rail for Lower Roll Forming machine | 1 line |

| 7 | Main body frame (Mezzanine deck) for upper roll forming | 1 unit |

| 8 | Free Roller Conveyors | 3 sets |

| 9 | Electric control | |

| B. Pre-heating system for Steel Facing | ||

| - Pre-heating system by Electric heater | 1 unit | |

| - Housing | ||

| C. High Pressure PU foaming machine -- 4 components | ||

| 1 | High Pressure PU foaming machine (4 components) | 1 unit |

| - 4 Flow meters | ||

| - 1 Mixing head | ||

| - 1 Display on monitor for each component | ||

| - 4 Metering pump units for ISO, Polyol, Pentane, Catalyst1, Catalyst2 | ||

| - 1 Air loading unit | ||

| - 2 Feed pump sets from tank to metering pump | ||

| - Machine Tank system (300L x2sets, 50L x2set) | ||

| 4 Sets of polyol and Iso tanks | ||

| 2 Temperature control System for Polyol & Iso tanks | ||

| 2 Heat exchanger for Polyol & Iso tanks | ||

| 2 Level gauge for each tank | ||

| 4 Feeding pumps | ||

| Necessary parts and accessories for each tank. | ||

| -1set of Water chiller (30RT) ----- Buyer scope | ||

|

D. Foaming portal for mixing head oscillation |

||||||

|

|

- Foaming Portal for oscillating movement of the mixing head |

1 unit |

||||

|

E. Safety control & Monitoring system for Pentane System |

||||||

|

1 |

- 6 sets gas detector (Gas sensor) - Control panel - Ventilation fan unit - Gas suction unit with Fan at Foaming zone - Pentane Cylinder and feeding system (Included) - Ducting system for gas suction to outside --- Buyer scope |

1 unit

|

||||

|

F. Double Belt Conveyor system, 24m |

||||||

|

1 |

Double Belt Conveyor (24m) |

1 line |

||||

|

2 |

Heating system for Double Belt Conveyor - Insulation housing - Auto. temperature control system - Electric Heater |

1 unit |

||||

|

3 |

Side Guide system by driving motor |

1 unit |

||||

|

4 |

Side Block system for total 4 sets. - Roof --------- 50mm ($ 15,000) - Boltless-------- 50mm ($ 12,000) - Cold room ----- 100mm ($ 20,000) - Support block for roof (Magnetic Type) ($ 22,000) ► Other thickness are optional items or Buyer scopes |

4 sets |

||||

|

G. Cross cutter by band saw & Disk saw for roof panel overlapping |

||||||

|

1 |

- Cross Cutter by band saw - Disk saw for roof panel overlapping cutting (Max. 200mm) - Clamping unit - Housing & Dust Collector ------------ Buyer scope |

1 unit

|

||||

|

H. Electric Control System |

||||||

|

|

- Electric control system for seller scopes (incl. Synchronization system) |

1 unit |

||||

|

I. Export Packing & FOB Cost (40' Container × about 20) |

||||||

|

|

- Export standard packing, Local Trucking Cost and Others in China |

|

||||

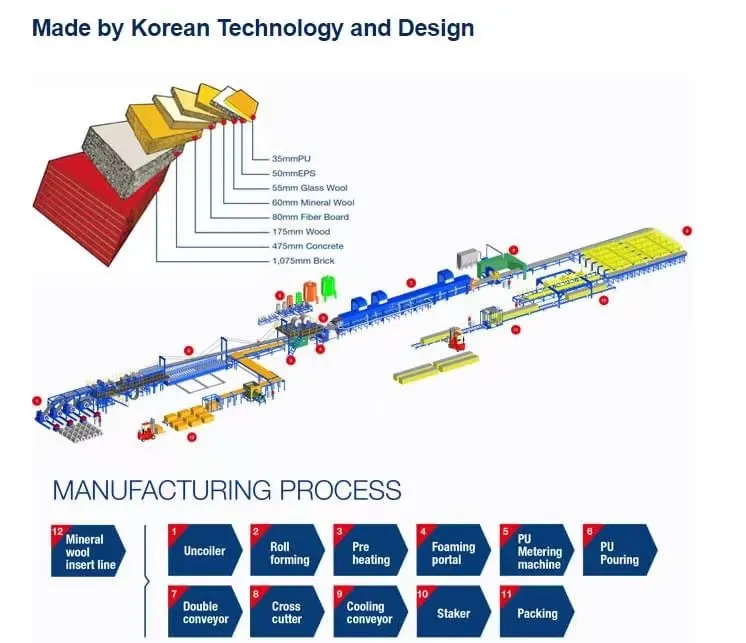

Technical Data

The below data might be a little changeable upon field conditions and manpower.

|

1. Roll Forming Line |

||

|

„ Coil (Raw material) |

: |

Pre-painted steel sheet |

|

„ Coil (steel sheet) thickness |

: Exterior (Lower) facing : 0.4-0.7mm Interior (Upper) facing : 0.4-0.7mm |

|

|

„ Coil weight |

: Max. 10 ton |

|

|

„ Coil width |

: 1070, 1200(1207), 1220mm (3~4 kinds steel) |

|

|

„ Machine length |

: About 40m |

|

|

„ Coil inner diameter |

: Æ508mm |

|

|

„ Coil outer diameter |

: Max Æ1,100mm |

|

|

„ Line speed |

: 0m ~ 8m/min |

|

|

„ Hydraulic pressure |

: Max. 150kg/ cm² |

|

|

„ Pneumatic pressure |

: Approx. 4 ~ 9kg/cm² |

|

|

„ Electric power source |

: 380v or 440v × 50Hz |

|

|

„ Forming type |

: Roof 4 rib and Cold room, Boltless panels |

|

|

„ Pass line (height) |

: 1,250mm from floor |

|

|

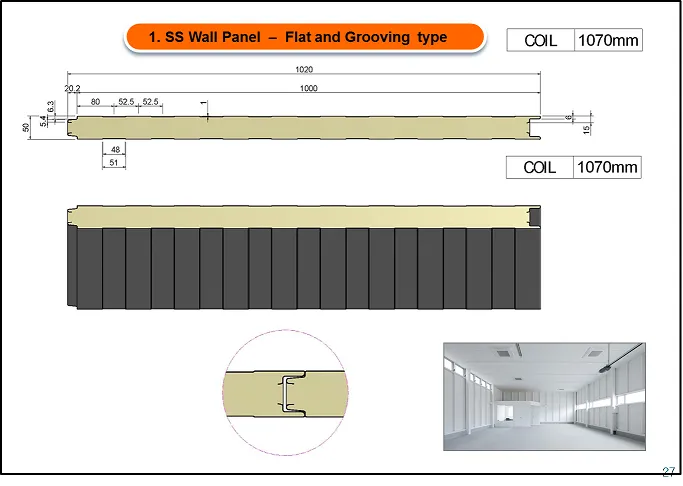

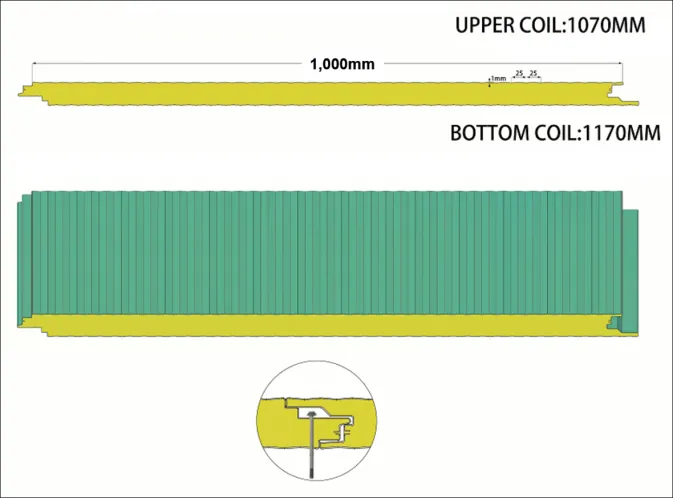

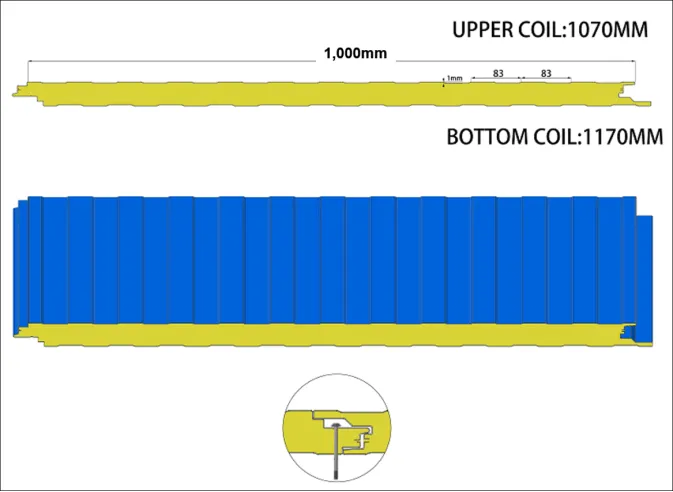

2. Panel & Insulation |

||

|

„ Panel types |

: |

Roof 4 rib and Cold Room panel, Boltless panel |

|

„ Panel length |

: |

Min. 2,000mm ~ Max. 15,000mm |

|

„ Panel width |

: |

Cover width : (Fixed type) - Cold Room 1,000mm - Roof 1,000mm - Boltless 1,000mm |

|

„ Panel thickness |

: |

35~150mm |

|

„ Foam property |

: |

PU/ PIR-rigid foam |

|

„ Foam Density |

: |

Approx. 35~50 kg/m3 |

|

„ Metering unit |

: |

High pressure pump system (2 or 4comp.) |

|

„ PU foam poured by |

: |

Oscillating mixing head |

|

„ Foaming pressure |

: |

Max. 0.5 bar/cm² |

Production Line Layout