|

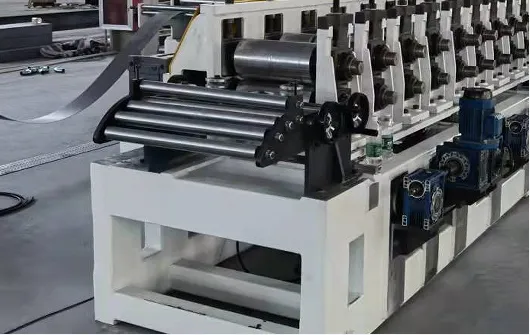

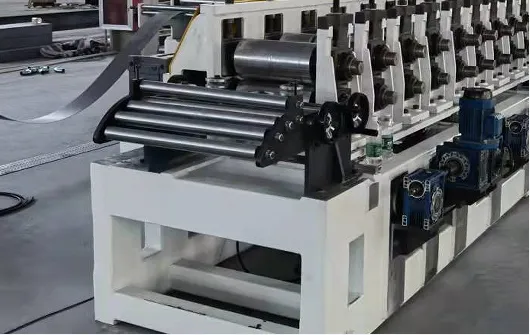

Decoiler with the leveling

- Uncoiler: Active feeding, hydraulic tension

- Capacity: 3T

- Inner diameter of uncoiler support coil: φ 508mm

- Support range: φ 470-530mm

- Steel coil width: ≤ 300mm

- Outer diameter of steel coil: 1300mm

- Hydraulic system power of uncoiler: 1.5KW

- Motor power: 3kw

- Leveling mechanism structure: two roller pinch, seven roller leveling

- Leveling roller shaft diameter: approximately φ 52.5mm

- Leveling roller material: high-quality 40Cr

- Leveling shaft heat treatment method: surface high-frequency quenching treatment

|

|

Servo feeding system with the punching machine

- Servo feeding: Driven by servo motor, feeding to the punching machine

- Servo feeder model: NCF-300

- Steel coil width: maximum 500mm

- Feeding power: 5.5kw (Yaskawa)

- Punch tonnage: JH21-80

- Slider stroke: 160

- Number of trips: 35-50 times/min

- Motor power: 15kw (Siemens)

- Die material: Cr12mov, quenching hardness HRC58-62

- Number of molds: 5 sets

|

|

|

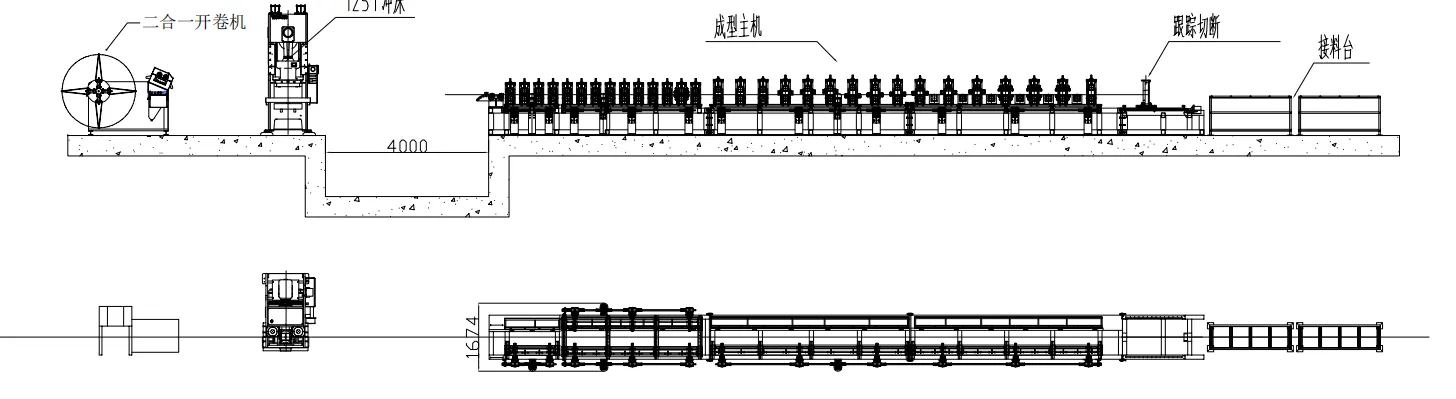

Feeding system

It is set at the beginning of the host to help the operator correctly adjust the direction of the inlet board. You can adjust the left and right side by hand wheels, and the number of feed is displayed.

|

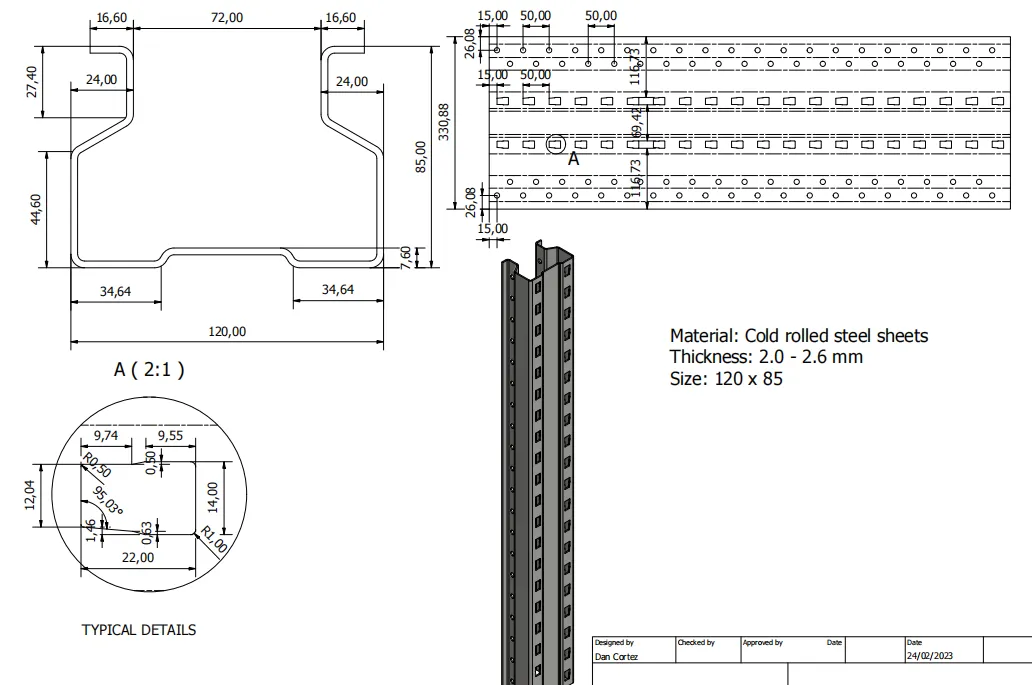

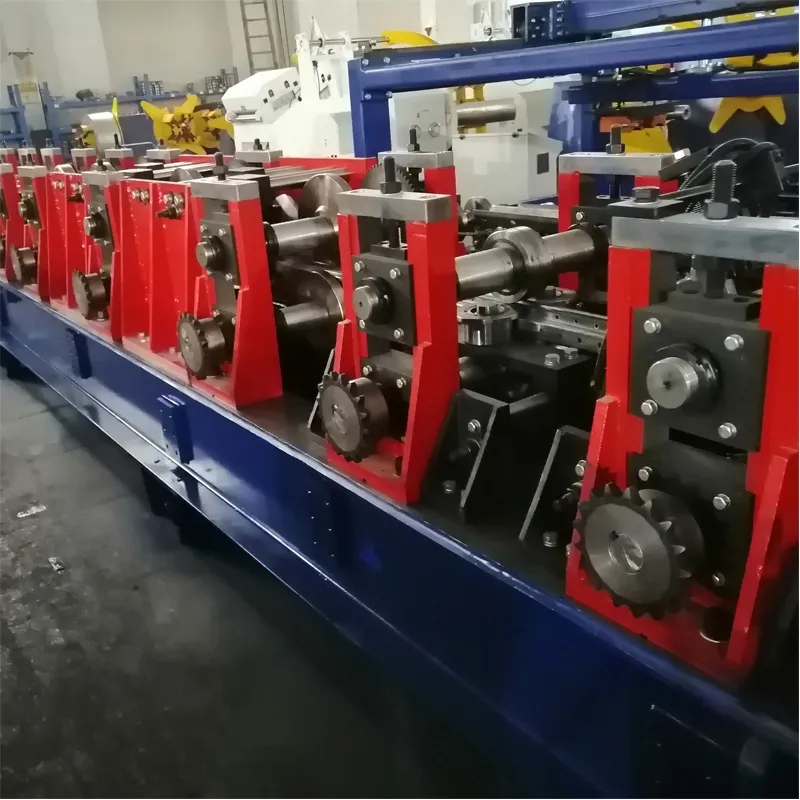

- Main roll forming machine

- Body structure: memorial archway

- Forming motor: 18.5kw

- Drive method: Chain

- Number of forming passes: 18 passes

- Roller material: Cr12mov, quenching hardness 58-62 °

- Shaft material: 40Cr, quenched and tempered (220-260)

- Main shaft diameter: Φ 80mm

- Bearing: Harbin Bearing

- Forming speed: 0-15m/min (excluding punching and shearing)

- Production line speed: approximately 0-8m/min (subject to design)

-

|

|

|

- Hydraulic cuttingwith servo track

- Working mode: servo tracking, hydraulic cutting

- Number of punching and cutting molds: 5 pairs, with blades of different specifications replaced

- Mold material: Cr12mov

- Hydraulic power: 11kw (South China)

- Servo motor power: 5.5kw

|

|

Receiving table

2000mm*2 Simple and powerless (corner steel welding, drum custard)

|

|

|

PLC Control system

1.Inverter: Anchuan (Japan)

2.PLC: Siemens

3.Computer operating panel: MCGS

4.Coder: Omron/Optical Ocean

5.Voltage; 380V, 50Hz, 3PH (can be according to customer requirements)

|