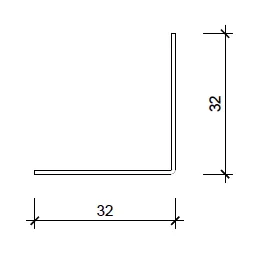

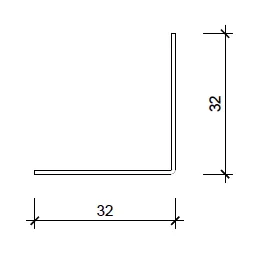

Drawing:

Processes and components

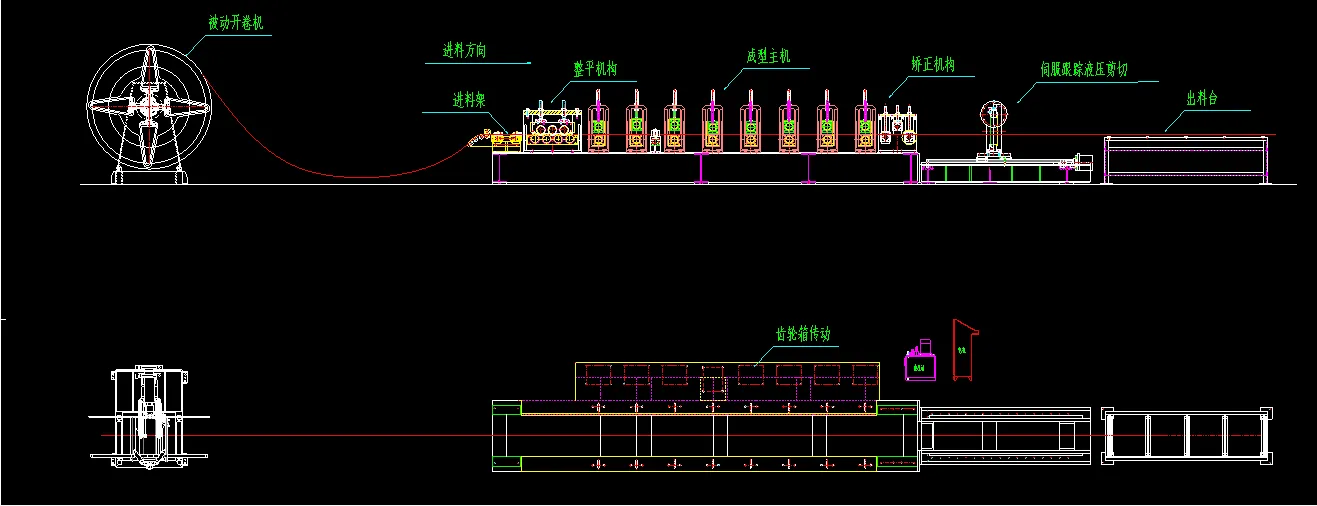

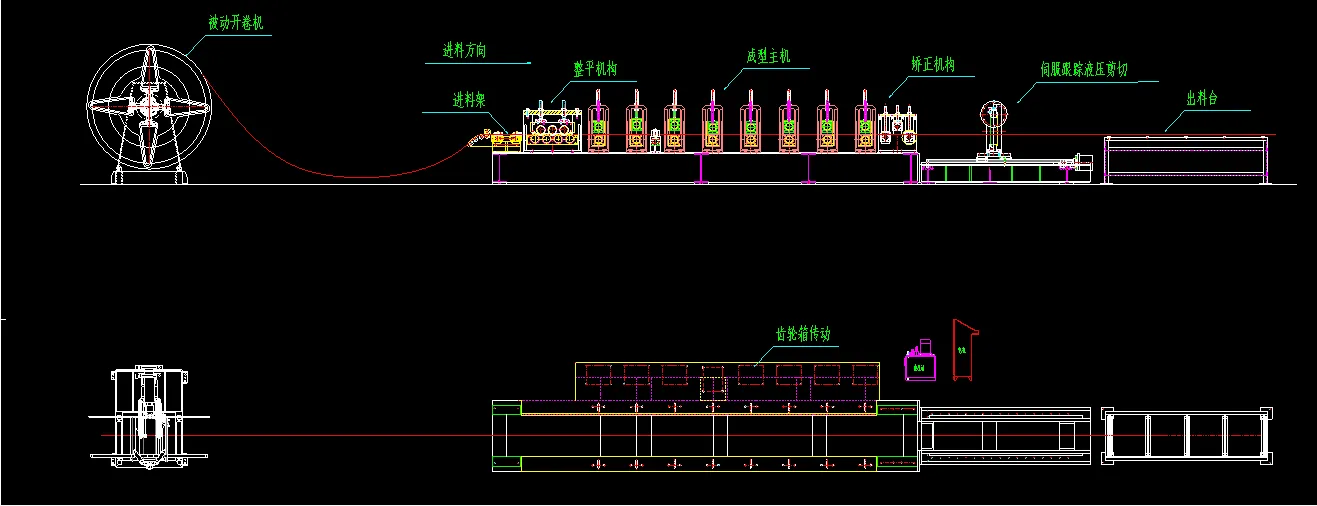

| Double hydraulic de-coiler |

x1 set |

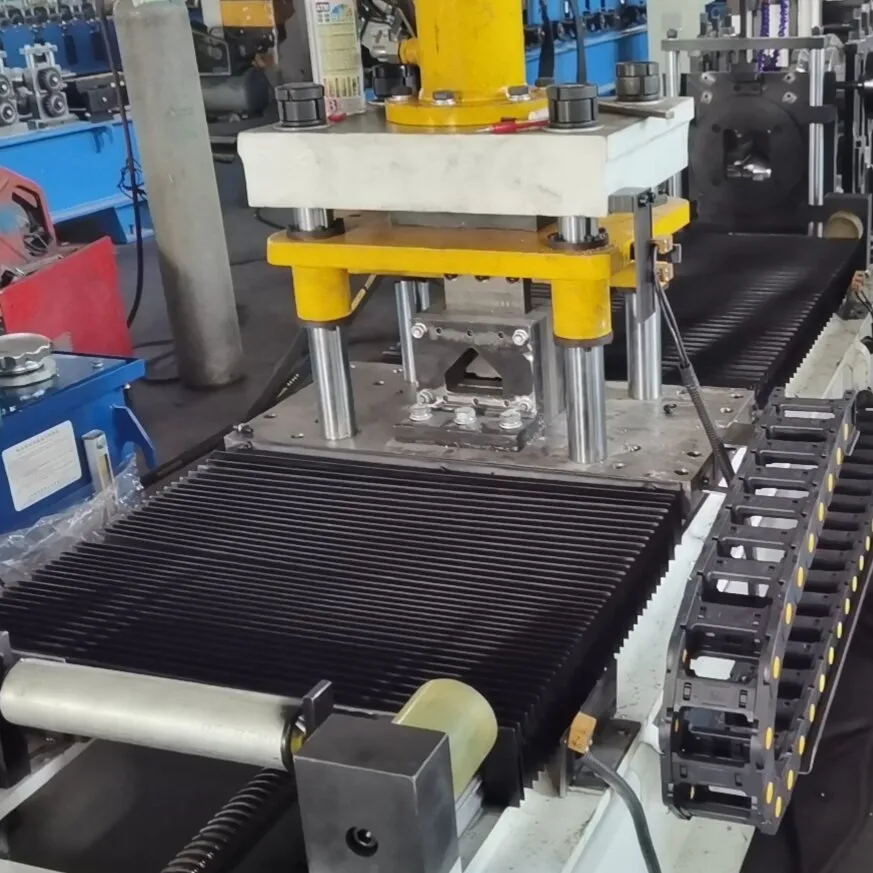

| Main roll forming machine x1set Servo follow cutting system |

x1 set |

| Hydraulic station |

x1 set |

| PLC Control system |

x1 set |

| Simple receive table |

x1 set |

| Cooling device |

x1 set |

Working Process

Technical parameters

1.Matching material: hot roll Q235/GI coil/black coil

2.Material thickness:1.2-2.2mm

3.Main motor power:37kw

4.Forming speed: 60m/min

5.The width of the plates:according to the drawings (18*18~45*45)

6.The formed width:according to the drawings

7.Roll stations:8 roller station

8.Shaft Material and diameter: material is 40Cr,¢60mm

9.Way of drive: gearboxdrive

10.Controlling system:PLC

11.Voltage: 380v ,50hz ,3ph ( as customer require)

12.Material of forming rollers: Cr12.

13. Material of cutter blade: Cr 12 mould steel with quenched treatment HRC58-62

14.Hydraulic station:11 kw

|

Angle Purlin Roll Forming Machine is a specialized piece of equipment used in the manufacturing of angle purlins, which are structural components commonly used in construction and building frameworks. These machines take flat steel sheets and roll them into the desired angle shape, providing strength and support for various applications, including roofing and wall systems.

|

|

Angle Purlin Roll Forming Machines are typically designed to work with various types of steel, including mild steel, galvanized steel, and stainless steel. The choice of material often depends on the specific application and environmental conditions the purlins will be exposed to. It’s essential to select the appropriate material to ensure durability and structural integrity.

|

|

|

The primary benefits of using an Angle Purlin Roll Forming Machine include:

1.Efficiency: The machine automates the process of forming angle purlins, significantly reducing production time compared to manual methods.

2.Precision: These machines are designed to produce consistent and accurate dimensions, ensuring that the angle purlins meet specific engineering requirements.

3.Cost-Effectiveness: By streamlining the manufacturing process, businesses can reduce labor costs and material waste, leading to overall savings.

|