I.Technical Parameter:

|

No

|

Name

|

Parameter

|

|

1

|

Control model

|

PLC DC control

|

|

2

|

Materials

|

Carbon steel

|

|

3

|

Yield strength

|

≤550 Mpa

|

|

4

|

Thickness

|

0.5-4.5 mm

|

|

5

|

Width

|

500-1500 mm

|

|

6

|

Coil I.D.

|

Φ480-520 mm(Φ508mm)

|

|

7

|

Coil O.D.

|

≤Φ1600mm

|

|

8

|

Coil weight

|

≤20T

|

|

9

|

Line speed

|

≤25 m/min

|

|

10

|

Cutting speed

|

it can cut about 1-2 pieces for 10m per minute;

it can cut about 3 pieces for 6m per minute;

it can cut about 4-5 pieces for 3m per minute;

it can cut about 5-6 pieces for 2m per minute;

it can cut about 7-8 pieces for 1m per minute;

|

|

11

|

Diameter of leveling rollers

|

Φ95 mm

|

|

12

|

Straightener rollers

|

17pcs

|

|

13

|

Material of leveling roller

|

GCr15

|

|

14

|

Harness

|

HRC56°-60°

|

|

15

|

Material of cutter blade

|

H13K

|

|

16

|

Diagonal tolerance

|

±2mm(L=2m)

|

|

17

|

Length tolerance

|

±1.5mm(L=2m)

|

|

18

|

Straighten precision

|

±1mm

|

|

19

|

Power

|

380V/50HZ/3PH

|

|

20

|

area of the whole line

|

25m(L)X7m(W)

|

|

21

|

The direction of whole line

|

From right to left

|

|

22

|

The color

|

Blue

|

|

23

|

Total capacity

|

Around 110KW

|

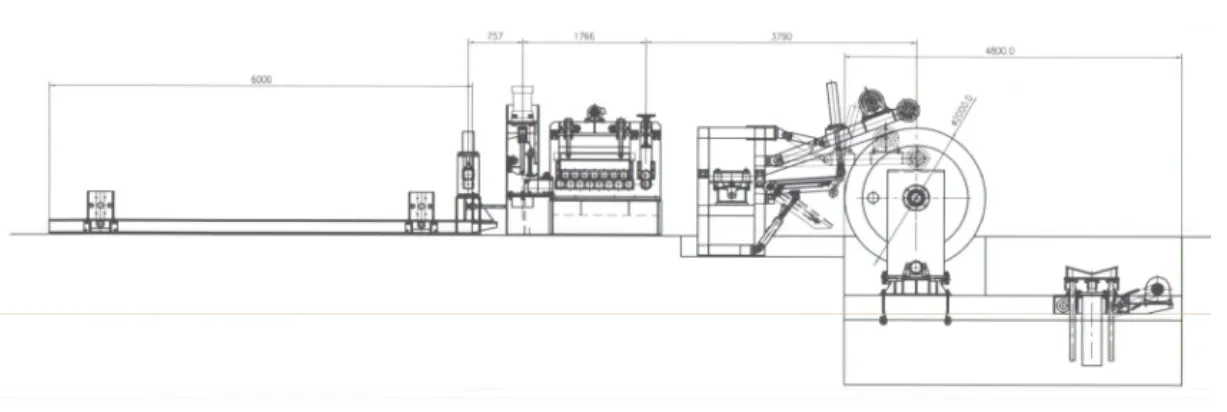

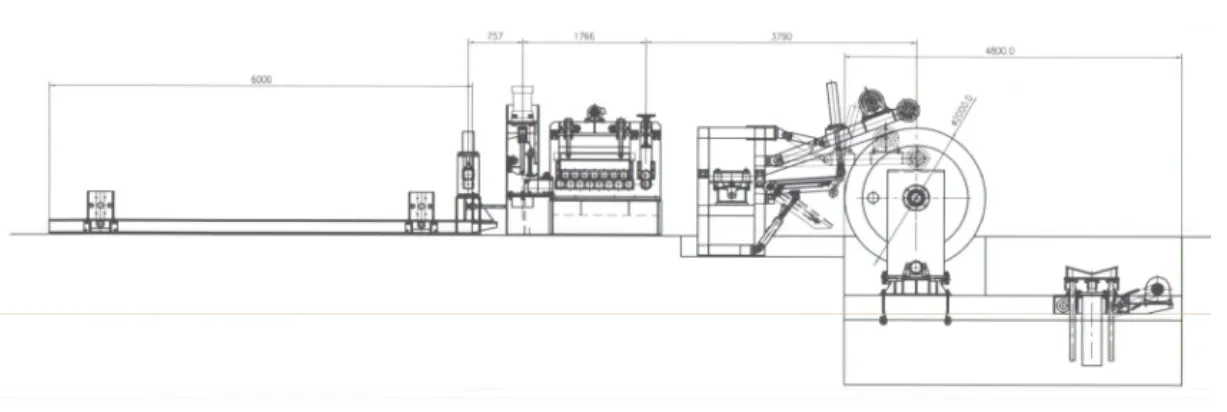

II. The flow of the process

From right to left, they are Uncoiler + coil car—Press device with side guide device—straightener + code device+Film cover device—Hydraulic cutting machine—receivable table .

III. Composed devices

|

No

|

Name

|

Quantity

|

|

1

|

Hydraulic entry coil car

|

1set

|

|

2

|

Hydraulic de-coiler

|

1 set

|

|

3

|

Hydraulic press and pinch device

|

1 set

|

|

4

|

Side guide device

|

1 set

|

|

5

|

Four-fold Leveler

|

1 set

|

|

6

|

Hydraulic cutter

|

1 set

|

|

7

|

Receivable table on ground

|

1 set

|

|

8

|

Pneumatic system

|

1 set

|

|

9

|

Hydraulic system

|

1 set

|

|

10

|

Electrical control system

|

1 set

|

IV、Brief instruction

- 1.Hydraulic entry car

◆The car can move levelly and vertically, which is convenient for putting the steel coils into the de-coiler.

◆It is driven vertically by hydraulic cylinder with four guide pillars.

◆The level movement is driven by cycloid motor.

◆The capacity of it can reach to 20Tons(MAX)

◆Function: It is used to lift up and down, move forward and back to make it easy to load the coils on decoiler. Hydraulic controls lifting, motor drives moving. The car is controlled on the auxiliary control panel. Its moving speed is 6-7m/min. When the coils on decoiler, the car will return back to the start position. It can also carry back the unfinished coils from decoiler.

|

|

|

2.Hydraulic de-coiler

◆Structure:Hydraulic expand and shrink to tight the inner hole of steel coils,Inner diameter:508mm.

◆The max capacity: 20T with hydraulic supporting stand.

◆4KW motor drive the coils running.

◆Function: Fixed the coil to achieve unwinding function, with brake. The car makes the inner holes of steel coils aim at the de-coiler center. The hydraulic expand and shrink de-coiler is driven by hydraulic, to tight the inner hole of steel coil.

|

- 3.Hydraulic press and pinch device

◆Two hydraulic cylinders controlled unwinding rubber roller lifting.

◆Hydraulic shovel head, hydraulic power shovel-head ect feeding steel plates.

◆Hydraulic pressing & guiding device: Driven by 15KW cycloid reducer motor. Setting manual clutch. Pinch roller pressed by hydraulic cylinders.

Drive mode using the lower roller drive. The diameter of hydraulic cylinder is: φ100

◆Structure: It is welding by steel plates and profiled bar

|

|

|

- 4. Side guide device

◆Connect with pinch and press device

◆It is composed of the frame, guide roller, adjustment device, movable platform and multi-roller wheel

◆The vertical rollers on the both sides guide the sheet right into the straightener.

◆Both sides of guiding vertical rollers adjust by the both ends of the screw by manual. The adjusting width is: 500-1650mm.

|

- 5. Fourfold straightening machine (45KW AC)

◆It is composed of 17 leveling rollers, 4 groups of supporting rollers, 2 pinch rollers ,driving device and frame. Both sides of each rolling wheel is transmitted by needle pins all are the main force rollers. The rollers diameter is φ95mm

◆The function of the supporting roller is to balance the leveling rollers force and reduce the friction to the rollers.

◆The working rollers can be adjusted the gap electrically which is controlled by 2 hand wheel to ensure the leveling quality.

◆Driving model: all the independent rollers and gear box are driven by 75Kw DC motor.

|

|

|

6.Cutter

◆Shear model: cut from up to down hydraulically which is cooperate with the signal direct from the feeder and shear automatically.

◆Adopt gap adjusting design to cut the materials and can shear 4.5mm steel plate safely.

|

- 7. Receivable table on ground

◆The length of plates can range from 1000-10000mm (which can be customized)

◆The width can be ranged from 500 to 1650mm.

◆Equipped with simple pneumatic stack to neat the sheets

|

|

|

8.Pneumatic system

◆The pneumatic system is composed of the air power (prepared by the buyer), air source treatment components , solenoid, relevant pipeline and air cylinder, etc. The components are adopted high quality products.

◆Technical parameters: stress of air source: 0.5-0.8Mpa. The capacity: 1m³ /min(compressive state)

|

- 9. Hydraulic system

◆Ensure the using of every hydraulic part.

◆The working pressure of the hydraulic system is 6.3-16Mpa.

|

- 10. Electrical system

◆Adopt PLC control mode, it is controlled the whole line fixed-length cutting by codes and count automatically.

|