- Manual decoiler

- Uncoiler: passivum unwinding, manual tensis

- Facultatem oneris afferens uncoiler: 5T

- Inner diameter of uncoiling machine: φ508mm

- Rolling range: φ460-530mm

- Rolling width: ≤500

-

|

|

|

- Ratio pascendi

- 1. Gubernata pascens : Cum lateralis cylindrus genus principale machinae cibationis diverticulum praebetur ducibus dextra laevaque, duo latera bracteae materiae rudis intrant machinam principalem a dextra et a dextra, ita ut laminam materiam rudis et volvulum systematis formandi rectam positionem teneant. Dux positio cochleae manualis mechanismo aptari potest, et laeva et dextra independenter aptabiles sunt. Dux volvunt exstinguitur.

-

- Adaequatio mechanismi compages: ancipiti ancipiti umbilici ternum, septem scutulis adaequandis

- Diameter of leveling shaft: Φ80 (Harbin Bearing)

4. Materia de aequandi hastili: 40Cr exstinguitur et temperata (HB220-260)

5.Surface curatio methodi aequandi hastile: super-finiens post altum frequentiam exstinguendi, chromium durum curationis plating

6. Methodus componit medium inter superiores et inferiores scutulis: Turbine elevator commensurationem

-

|

|

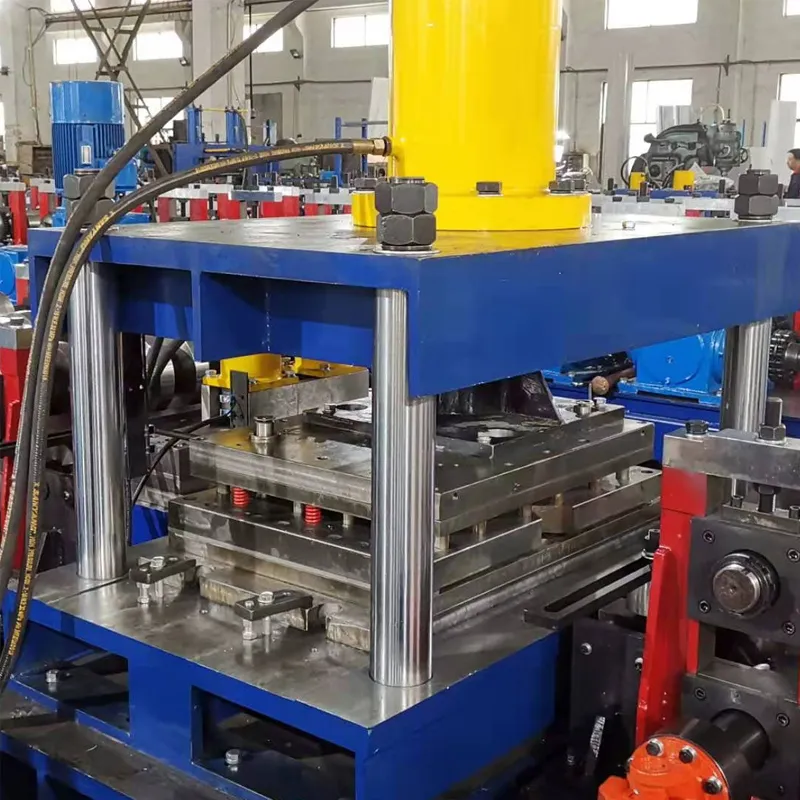

HYDRAULICUS systema pulsandi

1.Punching mechanism compages: quattuor columnae hydrau pulsare (prima lamina ferrum pulsare temperatur post welding)

2.Punching mori: I par

3.Material of upper and lower mortem of punch mori: SKD11 (HRC58-62)

4. Materia formularum superiorum et inferiorum: qualitas summus chalybis carbonis extinctionis et temperationis, processui super-finiens.

|

|

|

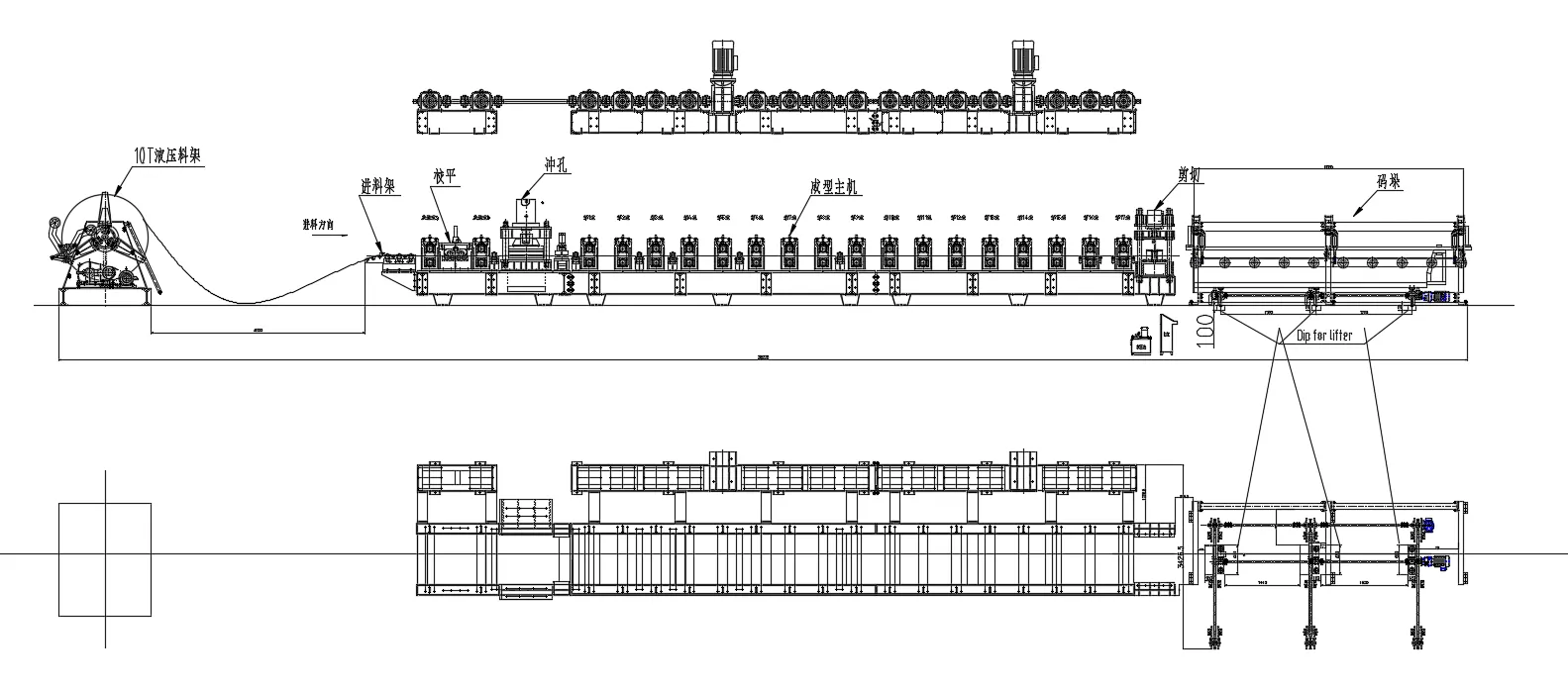

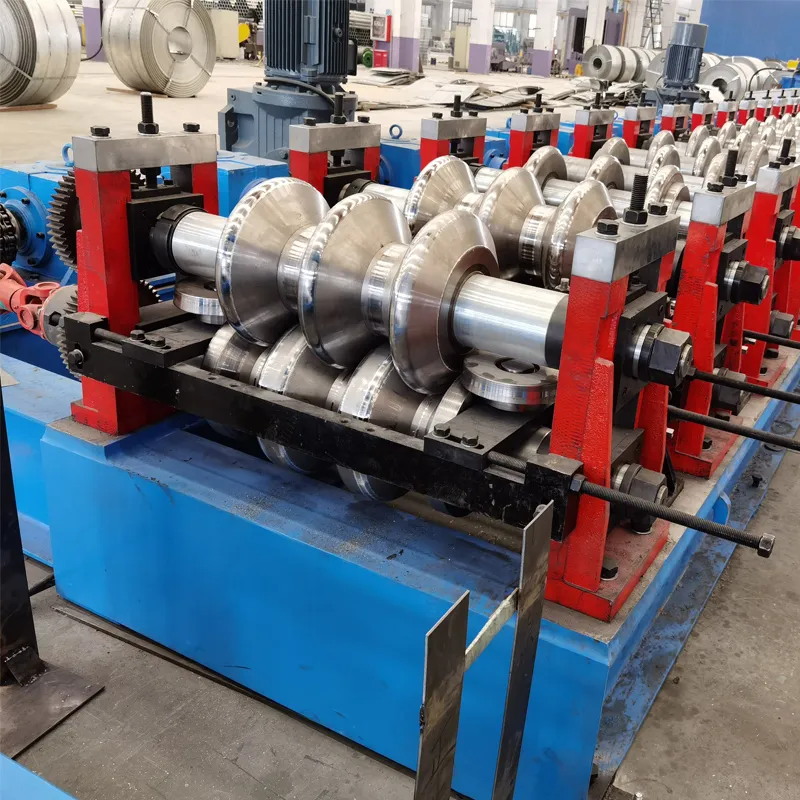

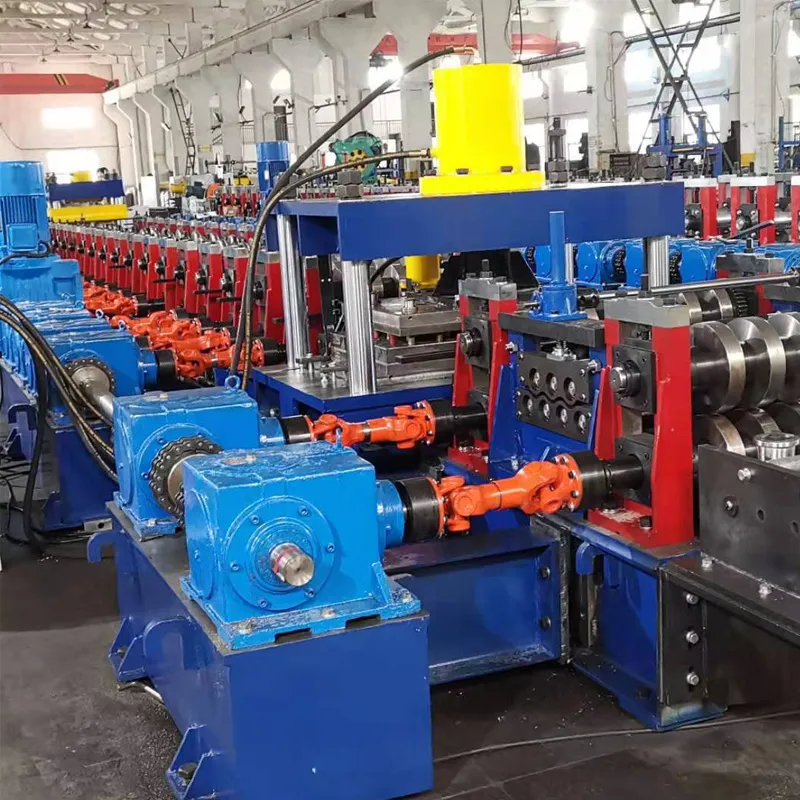

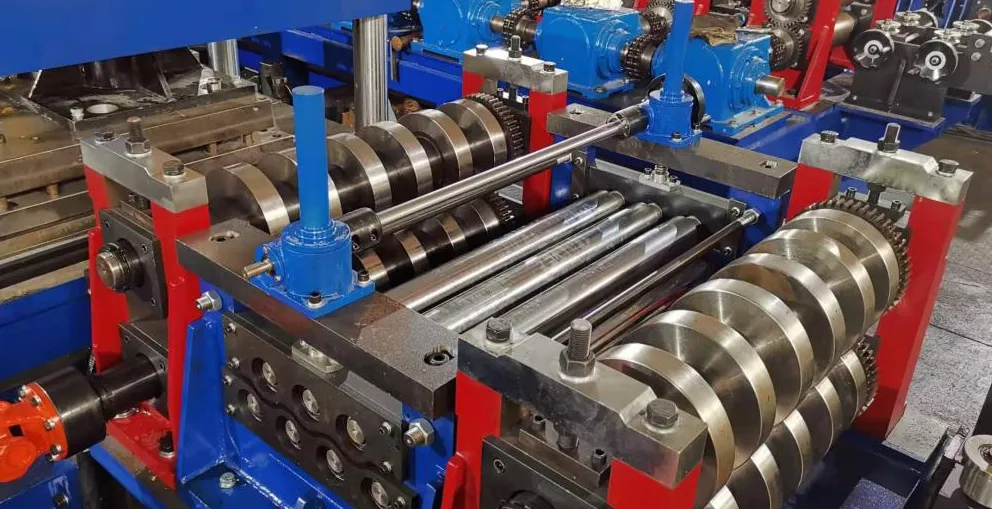

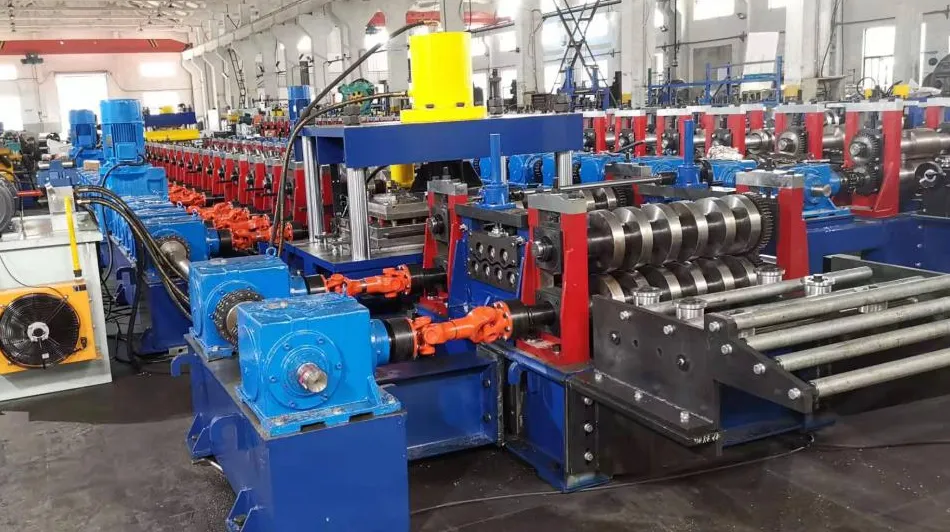

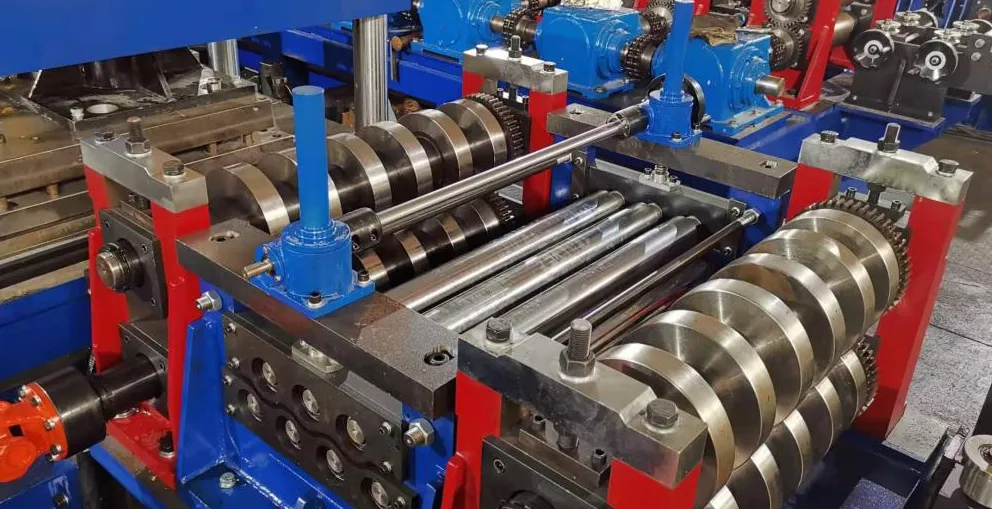

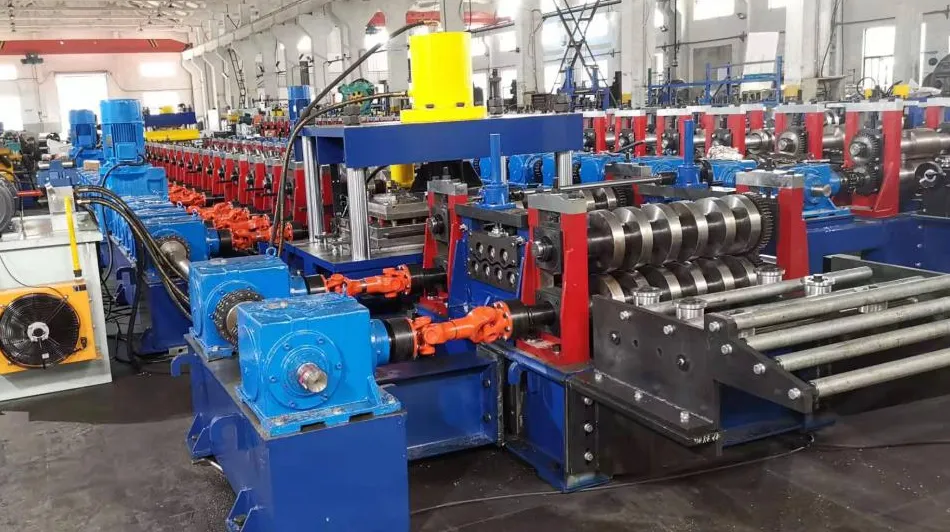

Roll machinatio

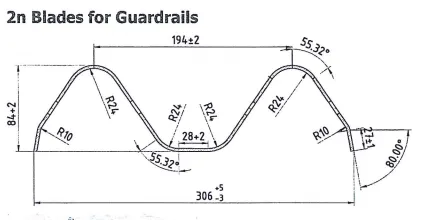

- Matching material: according to the drawing

- Materia crassitudo range: 3mm

- Pelagus motricium potentia: 30kw

- Formans celeritatem: 0-15m / min (includere pulsare)

- 5. Quantitas stat: circiter 12

6.Material of formatione scutulis: Gcr15

- Telum materiale et diametrum: ¢80mm,

materia : 40Cr curatio exstinguendi et temperandi (HB220-260);

8.Tolerance: 3m+-1.5mm

9.Controlling systema: PLC

- 10. Voltage: 220V/ 3phase/ 60 Hz

- 11. Roll caloris curatio methodus: curationis exstinguiendi (HRC58-62)

- 12. Forma processus methodi Roll: processus torno CNC

13.Forming machinae structuram: arcus ferreos gearbox transmissio

14.Gear arca exemplar: GY230 genus calces arca

|

|

Hydraulica sectione

1.Cutting modum: hydrau secans formans

2.Shear materia lamina: Cr12mov curatio exstinguitur (HRC58-62)

- 3.Hydraulic station power: 22KW

4.Hydraulic station structure: duo circuli

- 5.Hydraulic statione oleum sentinam: Poopus sentinam

6.Solenoid valvae: Beijing Huade (24V voltage salutem)

7.Cooling methodus systematis hydrau: aeris refrigerationem

|

|

|

- Automatic tassatori

-

1.Stacker length: 4.3 meters

2. Summa structura tassatori: tubus quadratus glutino cum cylindro labens

3.Lifting motricium: 3KW

4.Traverse motricium: 1.5KW

5.Cylinder adductius vacua

6.Electrical system control: principale electrica components adopt notae notae

|

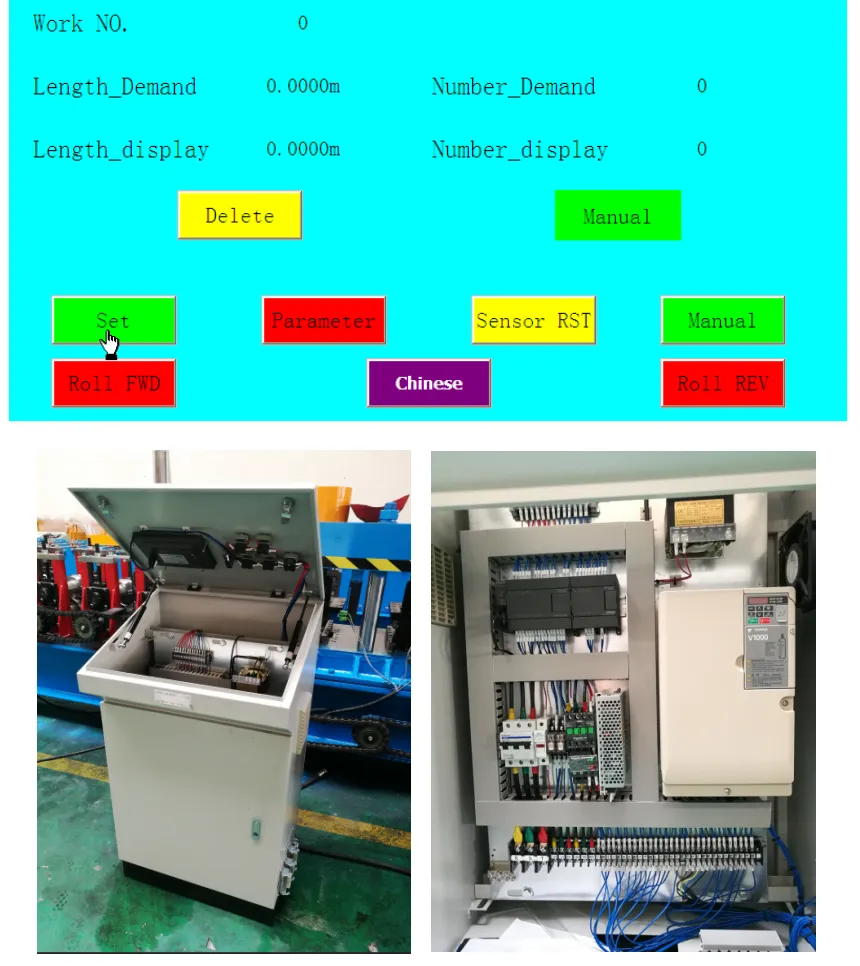

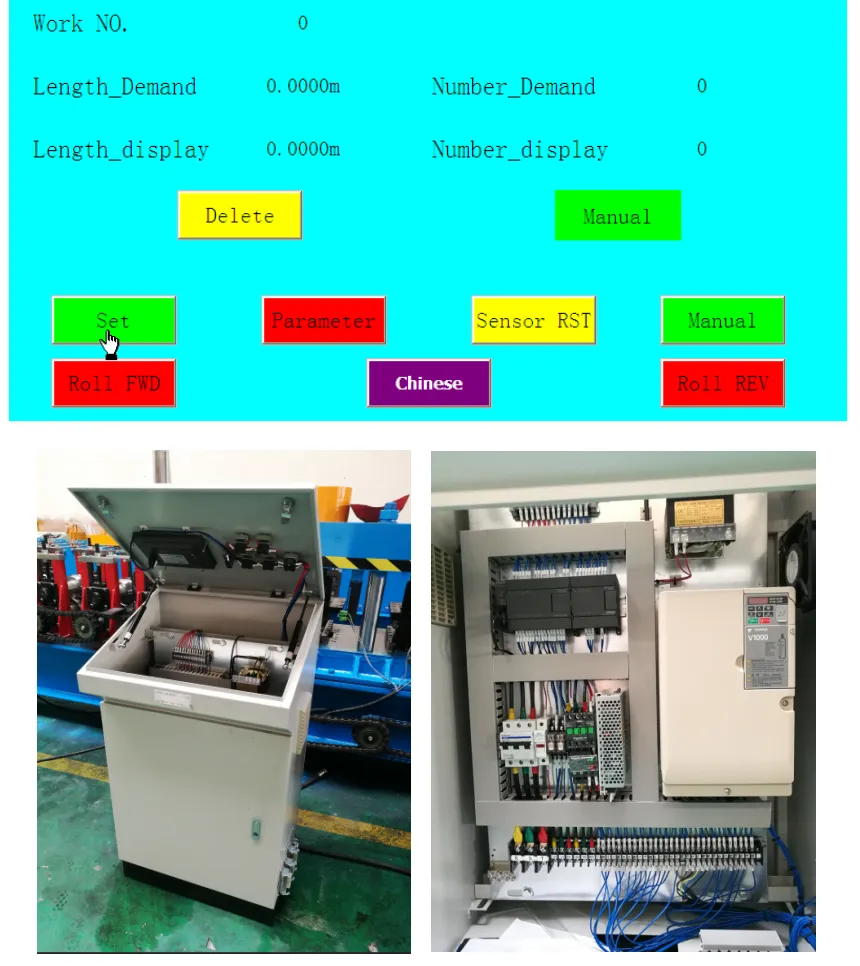

- Imperium systema

-

1.Inverter: Yaskawa (Iaponia)

2. computer PLC imperium adoptat: Panasonic

3.Computer panel operatio: MCGS

- Encoder: Learning

5.Voltage: 220V/ 3phase/ 60 Hz

6.Otherae electricae partes: omnes notae notae domesticae utuntur

|

|