Picture Display

Product Parameters

1.Component

|

NO. |

Machine Name |

Qty. |

|

1 |

Screw loader (For SJZ 80/156 & SJZ 65/132 extruder) |

2 |

|

2 |

SJZ 80/156 conical twin-screw extruder |

1 |

|

3 |

SJZ 65/132 conical twin-screw extruder |

1 |

|

4 |

Mould unit |

1 |

|

5 |

Distributor |

1 |

|

6 |

Embossing roller |

1 |

|

7 |

Temperature controller for Roller |

1 |

|

8 |

Glazed roof tile forming machine (32 pairs modules With ASA film unwinding device) |

1 |

|

9 |

Cutter with PLC |

1 |

|

10 |

Stacker |

1 |

|

11 |

Ridge tile forming machine |

3 |

|

12 |

Oven Chain type |

1 |

|

13 |

Ridge tile moulds |

4 |

|

14 |

Screw loader (For two sets mixer) |

2 |

|

15 |

SRL-Z300/600 Mixer unit (450-550kg/h) |

1 |

|

16 |

SRL-Z500/1000 Mixer unit (700-800kg/h) |

1 |

2.Project evaluation

|

Raw material |

PVC powder, CaCO3, CPE, PE-WAX, Stearic acid , Compound stabilizer ,ACR, paraffin,ASA granule |

|

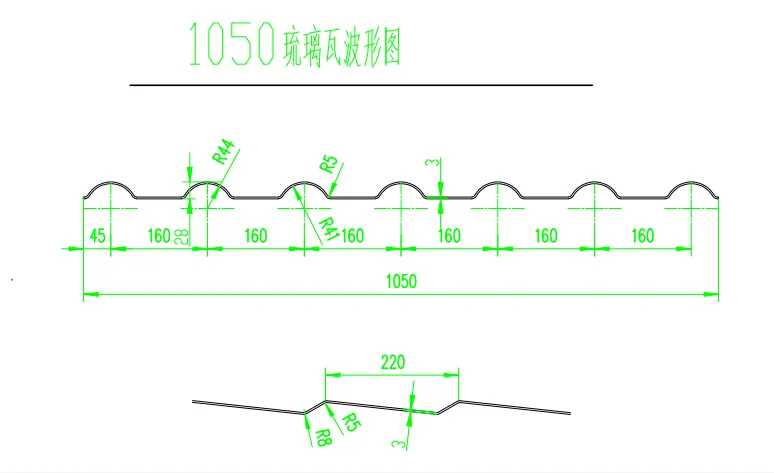

Description final product |

Four-layers PVC&ASA Glazed Roof Tile Width: 1040mm Thickness: 2.0-3.5mm normally |

|

Melt capacity |

400-450kg/h (Depending on CaCO3 proportion) |

|

Central height |

1000-1050mm (Customized) |

3.Work condition (Provided by customer)

|

Warehouse/Workshop |

Machine dimension: 25m(Length)×5m(width) ×3.5m(Height) Construction of foundations, construction works, earthworks, and wall works. Supply of cranes, fork-lifts or other lifting equipment; Mounting materials and tools. |

|

Temperature/ Humidity |

0-35℃/≤95% |

|

Power supply |

3-phase, 380V, 50 Hz |

|

Wire/cables/water hose: |

Wires/cables from power supply to control cabinet of this production line. All electrical cables from control cabinet to each machine. Water hose: supply water to machines and pools. |

|

Cooling Water |

Without dissolved or suspended minerals as phosphor, sulphur, iron, etc. Inflow temperature T1: max. 15℃; Outflow temperature T2: T2=T1+5℃; Hardness: 5-8odH; Reflux: without pressure |

|

Lubrication oil |

Exxon mobile |

|

Compressor |

7.5KW (0.6-0.8Mpa) |

4.Energy consumption

|

Installation power |

Around 300KW (Actual power consumption percentage: 70%) |

|

Cooling Water |

≤20℃, ≥0.3Mpa, 5-6tons/hr |

|

Compressed air |

0.3m3/min, >0.6Mpa |

|

Ancillary staff |

3 Persons/shift (24 hours need 2 shifts) |

5.Technical data

|

No.1 Screw loader |

||

|

Technical specifications |

Rated transmission capacity: 500kg/h Motor power: 2.2KW Pusher motor: 0.75KW Pipe dia: φ 102mm Pipe material: stainless steel |

|

|

Reference photo |

|

|

|

No.2 SJZ 80/156 conical twin-screw extruder |

||

|

|

Screw: Diameter: Diameter conical 80/ 156 mm Quantity: 2 sets Mesh form : Cone mesh Rotating speed: 1-36.9r/min Screw rotation direction: Anti-clock wise outward Features: 38CrMoAlA tempering, nitriding, surface plating hard treatment, strength HV950 and above, very wear-resistant; Screw handle adopts double flat key 180 degree distribution, uniform and reliable operating torque. Barrel: Heating method: Cast aluminum resistance heating ring Heating zones: 5zones Heating power: 24KW Temp range: 50-300℃ Cooling power and zones: 0.37kw×4sets Cooling way: Meter temperature controller, fan cooling |

|

|

|

Features: Barrel is made of double alloy material with tempering, carburizing treatment, hardness up to HV950.The inner surface is plated with hard chromium and polished. Drive system: Motor power: 75KW SIEMENS Work way: AC motor, elastic coupling connection Reducer: DELIN gearbox Debugging mode of main drive motor: Frequency control Features: Gear box is ductile iron and made of 20CrMnTi with nitriding, tooth grinding and other processes. All bearings in the box are international famous brands with long service life, high strength and surface hardness. Exhaust system: Brand of vacuum pump: ACEMIEN, double pump for continuous working Motor power: 3KW Work way: Direct Connector of spare pump: One vacuum pump with spherical connections Feeding system: Work way: Double screw feeding, automatic and quantitative Rotation speed: 0-63r/min Motor power: 1.5KW Features: The feeder is made of stainless steel and perform better than single screw feeder in the uniform and precise quantitative feeding Double screw feeding machine is designed for high calcium products, which will never be bridged in the hopper. Electrical system: Contactor: Schneider Air switch: CHINT Inverter: ABB PLC control: Siemens |

|

Reference photo |

|

|

No.3 SJZ 65/132 conical twin-screw extruder |

|

|

|

Screw: Diameter: Diameter conical 65/ 132 mm Quantity: 2 sets Mesh form: Cone mesh Rotating speed: 1-36.9r/min Screw rotation direction: Anti-clock wise outward Features: Wear-resistant screw is made from double alloy with treatment of conditioning, nitriding, hard chromium plated. The screw handle, connected with the distribution box by spline greatly increases the reliability of transmission torque. Barrel: Heating method: Cast aluminum resistance heating ring Heating zones: 4zones Heating power: 20KW Temp range: 50-300℃ Cooling power and zones: 0.37kw×4sets Cooling way: Meter temperature controller, fan cooling Features: Barrel is made of double alloy, treated by tempering, nitriding and hard chromium plating. The surface hardness is above HV950, which greatly improves the abrasion resistance of barrel and increases service life. Drive system Motor power: 37KW SIEMENS Work way: AC motor, elastic coupling connection Reducer: DELIN gearbox Debugging mode of main drive motor: Frequency control Features: Gear box is ductile iron and made of 20CrMnTi with nitriding, tooth grinding and other processes. All bearings in the box are international famous brands with long service life, high strength and surface hardness. Feeding system Work way: Double screw feeding, automatic and quantitative Rotation speed: 0-63r/min Motor power: 1.1KW Features: The feeder is made of stainless steel and perform better than single screw feeder in the uniform and precise quantitative feeding Double screw feeding machine is designed for high calcium products, which will never be bridged in the hopper. |

|

|

Electrical system: Contactor: Schneider Air switch: CHINT Inverter: ABB PLC control: Siemens |

|

|

Photo of machine |

|

|

|

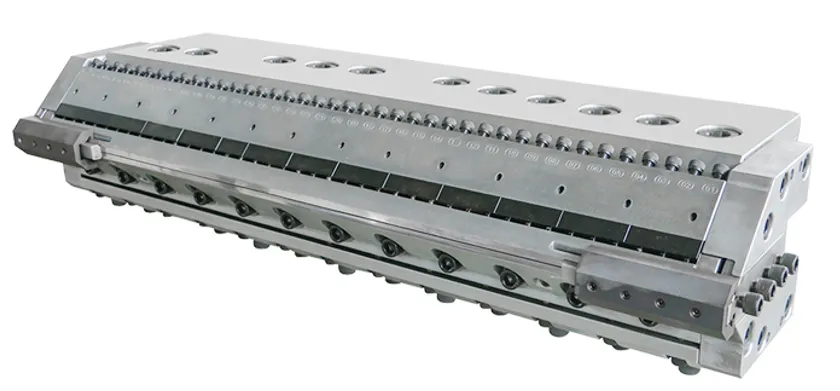

No.4 Mould unite |

||

|

Technical specifications |

23 |

|

|

Reference photo |

|

|

|

No.5 Distributor |

|

|

Technical specifications |

The distributor is designed as a block The overall flow channel is designed with 3d melt flow simulation software, produced in processing center, reached micron level, ensuring the one-time manufacturing of the mold and greatly reducing the number of mold repairs.

|

|

Reference photo |

|

|

No.6 Embossing roller |

|

|

Technical specifications |

Speed: 1-5m/min Driving motor: 1.5k×2sets Dimension of roller: φ295mm×1300mm Up roller is Embossing roller, the down roller is mirror Roller. Roller surface treatment by hard chrome plated (depth 0.10-0.15) Control System: ABB inverter The spiral runner is used in the roller, and the temperature of the whole surface is uniform, which ensures the embossing quality of the products. The upper and lower rollers are respectively driven by two motors assembly to ensure the synchronization of the upper and lower rollers |

|

Reference photo |

|

|

No.7 Temperature controller for Roller |

|

|

Reference photo |

|

|

No.8 Glazed roof tile forming machine |

|

|

Technical specifications |

Quality of module: 64 PCS (32 Pairs) normally Material: Aluminum alloy Extrusion Line speed: 0-3m/min Max haul-off power: 50KN Driver Motor power: 2.2KW Adopt ABB frequency inverter control Cooling mode: Fan cooling, 0.55Kwx8sets External connecting gas source exhaust amount: 0.67m3/min Exhaust pressure: 0.7MPa Moving of Forward and Backward Range: ±750mm Moving Motor power: 0.37KW Molding machine is designed with protective shell, safety and nice looking. Aluminum molding module is made of high quality aluminum alloy materials, one-time processing in processing center, versatility, strong interchangeability. driver module rack using 40Gr material, with surface quenching and black finished treatment, has higher strength and hardness. The transmission system use a pair of left and right hand to the turbine reducer in the module on both sides of the synchronous drive, transmission balance, reliable, convenient. The whole line is driven by a motor, advance and retreat Die set has air cooling device inside, which cool the back of the module directly and effectively. The distance of upper and lower modules can be manually adjusted to adjust the fullness of waveform. |

|

Reference photo |

|

|

No.9 Cutter with PLC |

|

|

Technical specifications |

Cutting mode: saw cutting motor power: 2.2KW Lateral saw-input :0.37KW Pneumatic control Equipped with special adjustable locator in order to ensure the accuracy of the location of each cut. Underfeed of the saw: The center of gravity of the machine get lowered and the operation become more stable. The dust is easy to be concentrated together by the dust suction fan, reducing the dust during cutting. The transverse feed is guided by precise light rod, which can be adjusted by motor deceleration system. The cutting speed can be adjusted according to the thickness of different products to ensure the aesthetic appearance of the product. Electrical control uses microcomputer automatic control, high reliability, without mistakes. Man-machine interface screen is convenient for adjusting cutting parameters and operation. |

|

Reference photo |

|

|

No.10 Stacker |

|

|

Technical specifications |

Material: stainless steel Length: 3000mm |

|

Reference photo |

|

|

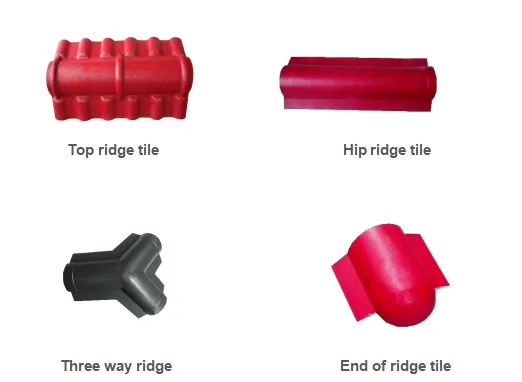

No.11 Ridge tile forming machine |

|

|

Technical specifications |

Cylinder control upside-downside Ridge tile mould: Alloy aluminum For 4 kinds of ridge tile of Glazed tile |

|

Reference photo |

|

|

No.12 Oven Chain type |

|

|

Technical specifications |

Length:3500mm, Width:1700mm Heating power 26KW, Transmission power: 0.75KW Capacity: 500 pieces within 8 hours High efficiency |

|

Reference photo |

|

|

No.13 Ridge tile moulds |

|

|

Reference photo |

|

|

No.14 Screw loader |

|

|

Technical specifications |

Rated transmission capacity: 500kg/h Motor power: 2.2KW Pusher motor: 0.75kw Pipe dia: φ 102mm Pipe material: stainless steel |

|

Reference photo |

|

|

No.15 SRL-Z300/600 Mixer unit |

|||

|

Mechanical parts |

|||

|

Hot-mixing |

Cold mixing |

||

|

Total volume(L) |

300 |

Total volume(L) |

600 |

|

Effective volume(L) |

225 |

Effective volume(L) |

380 |

|

Mixing time(min) |

8-10 |

Mixing time(min) |

8-10 |

|

capacity(KG/H) |

450-550 |

capacity(KG/H) |

450-550 |

|

Heating method |

Self-fiction |

Cooling method |

Inter layer water, cooling water ring |

|

Electrical parts |

|||

|

Hot mixing motor power(KW) |

55 |

||

|

Cold mixing motor power(KW) |

7.5 |

||

|

Speed controller for Hot mixing motor |

ABB inverter |

||

|

Motor |

DAZHONG |

||

|

Air switch |

CHINT |

||

|

Button |

DELIXI |

||

|

|||

|

No.16 SRL-Z500/1000 Mixer unit |

||||||||||||||||||||||||

|

Mechanical parts |

||||||||||||||||||||||||

|

Hot-mixing |

Cold mixing |

|||||||||||||||||||||||

|

Total volume(L) |

500 |

Total volume(L) |

1000 |

|||||||||||||||||||||

|

Effective volume(L) |

330 |

Effective volume(L) |

500 |

|||||||||||||||||||||

|

Mixing time(min) |

8-10 |

Mixing time(min) |

8-10 |

|||||||||||||||||||||

|

Capacity(KG/H) |

500-750 |

Capacity(KG/H) |

500-750 |

|||||||||||||||||||||

|

Heating method |

Self-fiction |

Cooling method |

Inter layer water, cooling water ring |

|||||||||||||||||||||

|

Electrical parts |

||||||||||||||||||||||||

|

Hot mixing motor power(KW) |

75 |

|||||||||||||||||||||||

|

Cold mixing motor power(KW) |

15 |

|||||||||||||||||||||||

|

Speed controller for Hot mixing motor |

ABB inverter |

|||||||||||||||||||||||

|

Motor |

DAZHONG |

|||||||||||||||||||||||

|

Air switch |

CHINT |

|||||||||||||||||||||||

|

Button |

DELIXI |

|||||||||||||||||||||||

|

Spare part list (free of charge)

|

||||||||||||||||||||||||