|

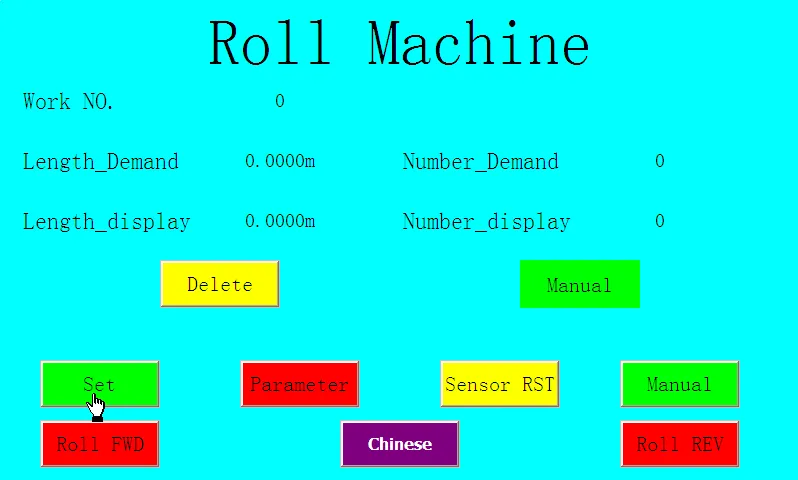

Control system

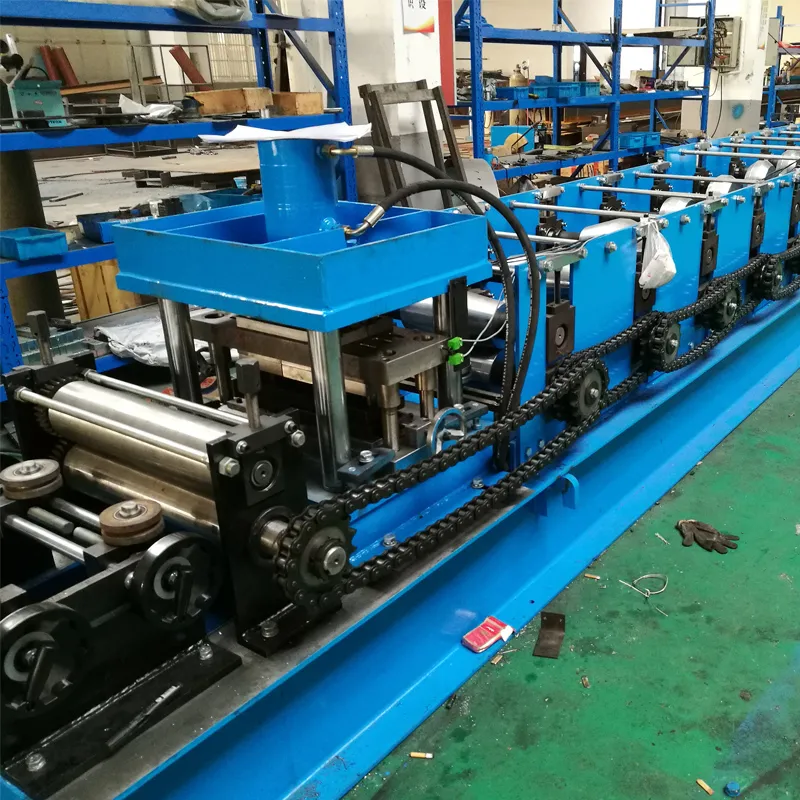

1) Control method: The whole line is controlled by PLC and operated by LCD touch screen. Operators control the production line and modify the control parameters, and can monitor the equipment operating status, operating parameters and fault indications in real time;

2) There are two modes of operation: manual/automatic: manual/automatic switching. A manual operation panel is provided next to the machine to facilitate the operation of workers:

In the manual state, it can perform stand-alone operation, which is convenient for maintenance;

In the automatic state, the whole line of production runs and starts sequentially. .

- Emergency control: It is convenient to install an emergency stop button at the operation place.

4) The design, manufacture and installation of all electrical distribution boxes and control cabinets comply with relevant national or industry safety standards. When all line electrical appliances and equipment are working, the temperature rise shall not exceed the standard rated value of the product. If necessary, install a ventilation fan in the wiring box, and the switch has good overload protection.

5) Distribution wiring: select high-quality shielded wires according to the national standards for strong and weak electrical wiring of industrial equipment.

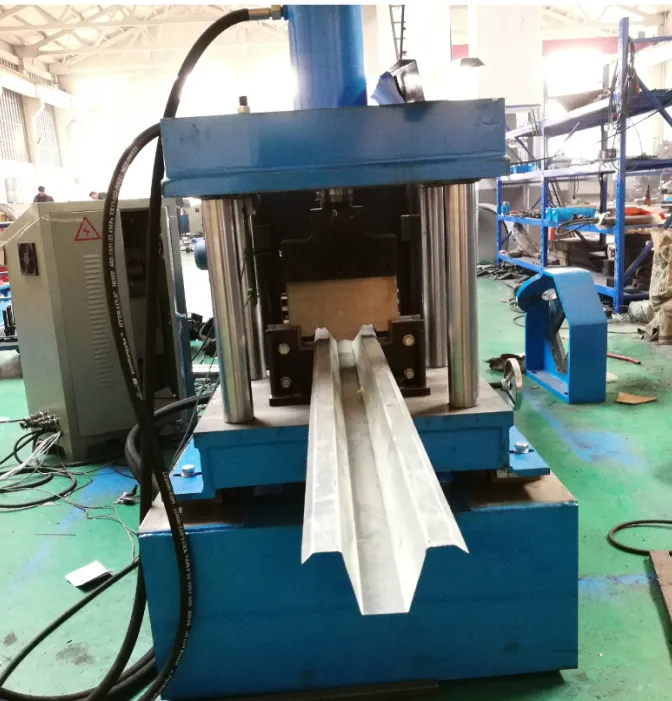

6) Through the program setting, it can: complete the one-time input of the specifications (length, hole position and size) and production quantity of various parts, and automatically calculate the production length and each hole of the profile according to the punching positioning rule provided by us The positioning of the die, the order of the punching die, etc.; at the same time, the strip material in the forming machine at the end of the operation (that is, the strip material between the plate cutting device and the post punching device) should be considered;

7) The program can control the automatic pulling of the material of the material rack, and automatically carry out the forming, punching and cutting. The same profile can be produced continuously, reducing waste;

|